Bikelab Report #2 – the Sun Lab and LED Taillights

This second issue of the Bikelab Notes, published during my time building BEHEMOTH at Sun Microsystems, focuses on the high-brightness LED taillight assemblies. These were not commercially available at the time, so this was a hack. I also commented on the wonderful facilities that Sun provided and answered a few reader questions. This was an exquisite phase of the project, surrounded daily by interesting people who came by the lab to volunteer, observe, or share a bit of brainstorming.

Bikelab Notes #2

December 16, 1990

©1990 by Steven K. Roberts

ROBERTS’ LAW OF APPLIED MOBILE GIZMOLOGY: If you take an infinite number of very light things and put them together, they become infinitely heavy.

A Booming Alias

Well, this has certainly struck a chord! As of this writing, 367 people have responded to the announcement of reports from the bikelab. This is gratifying, and a little scary: now my blithe prediction of weekly publication has to be taken a little more seriously. <gulp>

You know, there is something subtle about this whole Grand Turing Machine project that I am just now beginning to appreciate. I touched on it in Issue #1 (where I commented that I am just project coordinator for the REAL wizardry that must be credited to industry), and it was brought into sharp focus by an article in the Oct 1 issue of EDN about Richard Stallman of the Free Software Foundation. It spoke of the hacker ethic, which encourages cooperation and free sharing of information with the general intent of building the best tools possible, unhampered by legal constraints.

I believe in this, but I’ve also seen the awesome power of competition. It therefore seems that the best stance for me to take in publications about BEHEMOTH is to protect the intellectual property of my corporate sponsors, but otherwise disseminate the concepts and design details as widely as possible — either for free, or in value-added form via the <plug>print edition of Nomadness</plug>. Industry has made this enterprise possible by contributing ideas — and it’s only fair for me to complete the cycle, so to speak, by freely sharing information in return.

And this publication is the vehicle for that. Enjoy, and please feel free to redistribute this without charge and write with feedback and questions…

Feedback and Questions

This regular column will present a few specific reader comments in each issue. To maximize your chances of getting a letter published, please make your questions well-focused (I’ve had some that require about 10K of text for a cogent answer). I do edit for clarity and brevity…

From Brian Lloyd of Telebit:

Last time I spoke with you, I enquired about sources for recumbent bikes. I find the riding position on standard safety bicycles too uncomfortable (I have a neck and back malady that causes problems with the head-up riding position). I would like to construct a smaller version of your bike without all the features you carry. I would probably limit it to a single processor, cellular phone, and two meters. There has to be a way for those of us without millions of $$$ to accomplish some of the same things that you have.

One other item: the product that we (Telebit) have recently unveiled will be of interest to you. It is an IP router that establishes its link with the network using on-demand dial-up links. Imagine that someone in the Internet needs to establish a session with your bike (mail, transfer a file, etc.). They simply route the packet to one of our NetBlazers and it calls your bike via cellular phone. Likewise you can initiate the connection via CellBlazer from your bike. Imagine having your built-in SPARCstation on the Sun network wherever you go but having the phone connection active ONLY when there is traffic going back and forth.

Wow! I want one. I’m rapidly getting addicted to the Big Network… these are some pretty powerful tools. They are changing my expectations about how datacomm from the bike should work: stopping at the occasional pay phone and plugging in the cups no longer seems particularly appealing. The product you describe sounds like pure magic, and the ideal solution for this nomadic application. Where do I sign? (NOTE to readers: We have since spoken and this looks like it will indeed happen… watch future issues for details.)

As to the recumbent, a good approach is to contact Dick Ryan about the Ryan Vanguard recumbent. It costs about $1,000 and is one of the best made commercial recumbents I have ever seen. The company is in Malden, MA. Two other resources of note are the Recumbent Bicycle Club of America and the International Human Powered Vehicle Association. Both have excellent publications.

A brief comment on the bike’s TCP/IP link from Courtney Duncan, N5BF:

Yeah, Cellblazer-like things are leaving hams in the dust. You’re going to be able to remotely mount just about anything in the world just so you can talk to me on e-mail about how to make an amateur 1200 baud twice-per-day satellite connection (that will only work after lots of trying).

Hmm.

Responding to my comment about starting the next journey with RAGBRAI (across Iowa in July), Chuck N6GAL inquired:

Does this mean you’re not starting the grand tour from here? Will there be no opportunity for those of us still chained to our desks to spend a few days riding with you?

Actually, there will be some kind of shakedown in this end of the world before July. I rode all the way to Sunnyvale last week to visit Trimble Navigation and do an open house with Ampro, and even that short flat ride demonstrated how badly I’ve gotten out of shape. I’m planning a one-week loop to Pinnacles National Monument sometime in the spring, and everyone interested is invited… I’ll post the details to this alias as they develop. Hope you can come along!

Now a power management question from Larry Fiedler here at Sun:

I understand that you rip out the power supplies on the computers and use your own +5V supply from the bike. Does this cause you any problems, or is it as straightforward as I think? I suppose you need to solder in a power switch. Is there much voltage level fluctuation, and if so does this ever cause a problem?

Basically correct — I run a raw +12 (more or less) battery bus throughout the whole bike, and then spot-regulate with dedicated DC-to-DC converters tweaked to each load (MAX638 for most of the 5-volt stuff). It’s hardware intensive, but maximizes conversion efficiency. The switching is all electronic via FETs, under control of FORTH tasks in the 68HC11 systems. Another benefit of this is minimization of noise propagation — trash in one area is not likely to become global.

Finally, this from Joe Reed, N9JR, somewhere in Wisconsin…

Thanks for issue 1 – it blew me away. Sounds like a ham dream! Now since you have the HF antenna problem licked, are you running PacketCluster and have you developed the ability to QSY to the DX spot frequency? That might make mobile dx’ing a bit easier on a busy highway. Depending on the transceiver you use it should be a fairly simple programming task

<grin> Well, now there’s an angle! Actually, I’m not much of a DX chaser — my pleasure in ham radio is making friends, and the frenzy of a pile-up seems to accomplish quite the opposite if you’re not careful. Being on the bike in strange places might put ME in the hotseat, come to think of it… and an endless succession of “QSL, you’re 5-9 in Kamchatka, QRZed?” doesn’t sound like much fun, especially if there’s an expectation of QSL cards….

Seriously, though — automatic control of the transceiver (an Icom 725) is no problem… it all happens via a serial line reachable through the network by any of the console processors. I’m sure some interesting applications for that will develop!

Snapshot of the Bikelab

I’ve had a number of questions about the project environment here, and before going into this week’s feature tech article I think a quick description of the lab is in order.

It’s wonderful! Sun has provided about 1200 square feet of windowless lab space in the relatively unpopulated MTV-4, along with all necessary hooks to the outside world. The windowless part is not as bad as it sounds — it keeps me from getting seduced by sunny days. Lighting is a blazing array of FLUORESCENTS (inevitably, an acronym: Fiendish Lights, Uniformly Obnoxious Retina-Eating Soporific Cylinders of Evil, Noxious, Toxic Substances), though I do have a few normal lights to soften things — like now, when I’m bathed in the glow of a SPARCstation 1+ at 3 A.M., trying to push buttons in the right order while listening to jazz.

The computer room is a cubicle in the corner, with three systems — the SPARC, a Mac SE/30, and a generic 386 DOS machine. Fortunately, the chair has wheels — I use all three machines daily and am wearing a delta-wye-shaped path in the carpet. A folding futon stashed under one of the worksurfaces gives me a break now and then.

Next to the office is the machine shop, dominated by Cecil (Cecil be da’ Mill). This is a classic 1960 Rockwell knee-type milling machine I bought via misc.for-sale, and next to it are a grinder/sander, vise, and the other tools of a basic beginning machinist’s shop. I try to keep metal bits from sailing over the partition to mingle with the electronic ones…

Along one long wall of the lab proper are four lab benches, astrewn with all the usual clutter of hardware hackerdom. Test equipment — scope, distortion analyzer, SCSI bus analyzer, power supplies, and the like — is scattered around, along with various laptops and other development tools. A variety of cabinets and shelving units spill over with inventory and far too many magazines, antennas lie about on the floor, a camping-gear area overflows one corner, and in the middle of it all is a 12-foot BEHEMOTH — sometimes linked via umbilici with the benches.

It’s quite a playground, but I still have tire itch. 31 weeks!

LED Taillights

One of the classic concerns about bicycle touring, for lots of good reasons, involves lighting and safety. If you look at the situation statistically, it’s terrifying: even if only one in every 100,000 drivers runs over you, it’s still going to happen eventually if you spend a few years on the road. It thus makes sense to make every effort possible to be VISIBLE, and I don’t mean just screwing on one of those dinky commercial bicycle taillights that runs on a few penlight cells.

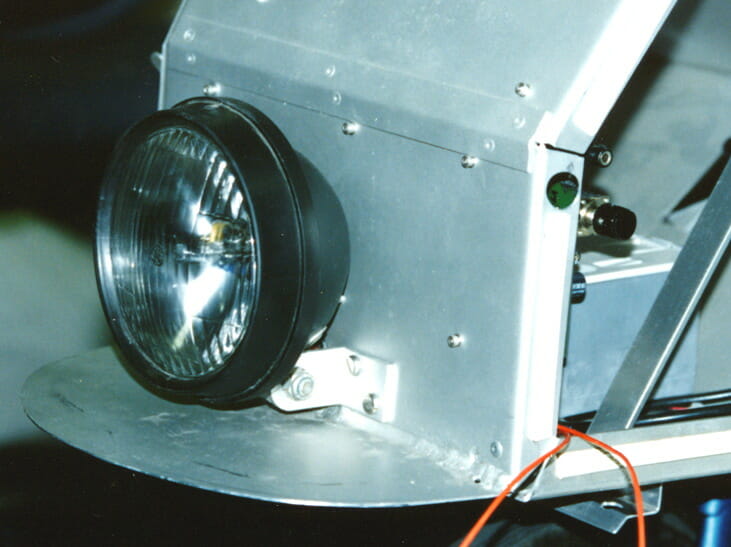

My overall lighting system consists of a 4″ 20-watt sealed beam quartz-halogen fixed to the bike, a Night-Sun dual-beam unit on the helmet (with 8 watt flood and 30-watt spot), a yellow 7″ highway barricade flasher behind the seat, a round bicycle taillight, and a pair of 2-section taillights on the trailer to provide steady-on, turn signals, and hazard blinkers. There are also reflectors all over the place, an orange safety triangle on the back of the trailer, two gaudy flags, a couple of utility lights for the operating position, and possibly front turn signals if I’m feeling ambitious when I re-do the fairing.

This article is about the taillights… how to make them bright and reliable while drawing a minimum amount of power from precious and heavy batteries.

Recent developments in optoelectronics have made this possible — with Hewlett-Packard, Stanley, and Ledtronics offering high-brightness LEDs with intensities ranging from 3 to 15 candela at 20 mA. Viewing angle is relatively narrow (typically 7 degrees between half-intensity points), but otherwise they behave like any other LED, dropping about 2 volts and getting brighter for a given voltage as the ambient temperature drops.

Many automakers, including Nissan, are using these for high-mounted stop light (CHMSL) assemblies — for good reason. Basically, why start with a lot of radiation (heat) that happens to include some visible light, then throw away most of the visible stuff to get red? A typical single taillight bulb, like the GE 1816 I used for 16,000 miles, draws about 330 mA; a brighter LED cluster draws 50 mA. The choice is obvious.

BEHEMOTH now carries three LED taillight assemblies. The simplest one is on the back of the RUMP (the fiberglass enclosure behind the seat) — two parallel chains of 7 LEDs each, packaged on perfboard in a 2.5″ diameter Peterson marker light assembly from an auto parts store (I just clipped out the original incandescent mounting hardware). Ten of the LEDs aim straight out through the lens; four aim sideways to increase visibility from wide angles. The fresnel-like lens adds enough dispersion to yield a very satisfying and bright light.

The trailer lights are a bit more complicated, and are built into Peterson PM-13812 clearance lights, designed for two bulbs. Each .7X1.4″ perfboard cluster of 14 LEDs (top steady, bottom flash) is fixed to the body by Panduit foam mounting tape and a little spacer of lexan Thermoclear (very light double-wall glazing), and four wires are routed through the trailer wall. A clean mounting to the curved trailer surface was achieved with a gasket of half-inch Poron cellular urethane, belt-sanded to shape.

Electrically, we now have two LED clusters (each consisting of 2 parallel chains of 7 junctions, totaling 50 mA) in each trailer taillight, plus the one on the bike. Now what? Hooking them directly to a lead-acid battery bus would be a disaster — voltage varies all over the map with temperature and charge conditions.

The answer is a small controller board. A major component is a little DC-to-DC converter (in this case, an adjustable-output “DC Battery Adapter” made for the laptop market by Product R&D). I set this to about 13.25 volts, which remains constant over an input voltage range of 10-15V. It is turned on via 1N5817 schottky diode switching whenever any light switch is activated that calls for LEDs (trailer tail, bike tail, hazard blinkers, or either turn signal).

In the case of steady-on lights, that’s all that happens: DPST light switches source +12 to the supply and ground to the associated LED cluster. But any of the three blink conditions power up another part of the board — a 7555 CMOS timer with steering logic to let turn signals override blinkers. This is set to about 1 second with a 50% duty cycle, and yields a nice stable flash, switching ground to the appropriate LED clusters via IRFD113 N-channel power MOSFETs in mini-DIP packages. When a turn signal is active, the flash signal is also passed to a piezoelectric beeper. (All electronic parts were from Halted Specialties in Santa Clara).

This circuit was a handy place to control the yellow barricade flasher, as well. Originally, this light was a product from Bicycle Lighting Systems of Falls Church, VA (though everyone seems convinced I stole it from a construction project somewhere along the way — I look like a roving hole in the road), and it came with a little 2-transistor oscillator board. It worked pretty well, but is old, corroded, and generally un-hackable — so the bulb is now driven by the opposite phase of my 7555 timer, giving the whole system a nicely coordinated look.

Overall efficiency is excellent. The CMOS is basically free, and the DC-to-DC converter costs about 260 milliwatts in exchange for about 1.2 watts to a pair of LED clusters. Not perfect, but still well below the wasted power in the incandescent units (about 8 watts per pair). In other words, we’re getting brighter light, better aesthetics, a crisper blink, and much higher reliability for about 1/6 the power. Such a deal…

That’s it for this week — I’m trying to keep the length of these reports under control. This week I’m off to Novato to pick up a printed-circuit-board milling machine from Instant Board Circuits, meaning quick-and-hopefully-easy prototypes.

Cheers from the BikeLab!

You must be logged in to post a comment.