First Amphibian Launch of the Microship

This posting to the huge Nomadness mailing list was a pivotal one… it was the first reality check of the Microship with deployable landing gear. The event was described in the local paper a few weeks later, but the text below tells the story in much more satisfying geek detail, and the entire decade-long project narrative has a page of its own…

Microship Status Report #131

by Steven K. Roberts

Camano Island

September 22, 1999

“Re: procrastination… it’s good.

It guarantees you have something to do tomorrow.”

It’s been 3 months since my last missive to you folks… it’s not that I didn’t have anything to say, I just couldn’t bear the thought of yet another issue bemoaning the complexities of work in progress without some FUN thrown in. That is, after all, the bottom line.

And so, I’m delighted to report that yesterday… after weeks of missed deadlines including the Sea Kayak Symposium last weekend, after 3 days of false starts terminated on the gravel driveway with landing gear failures, I finally strapped on a harness and hauled the Microship a mile down the road and launched her gingerly into Saratoga Passage. This has been the holy grail of the Microship project for almost a year, driving us through crazed all-nighters and epic machining projects, months of hydraulics hacking, reams of arcane calculations, and the interfacing of components designed for half-ton shock loads with the delicate skins of a canoe.

But she works.

I gotta tellya, it was beautiful: ambling downhill with a folded 20-foot trimaran in tow to the bemused expressions of passing drivers, rolling ‘er into the water with nary a trailer or tow vehicle in sight, pulling levers to retract the landing gear, deploying the hydraulic rudder and pedal drive unit, and zipping off across calm waters at about 4 knots on pizza power. Later, when a zephyr at last rippled the surface, I pulled a couple of lines to unfurl and outhaul the sail, popped the daggerboard down, retracted the drive unit, and I was sailing — a turnkey operation. I won’t talk about what it felt like to haul the monstrous machine UP the killer hills between the launch and the lab… surely it’s just a matter of getting in shape <creak>.

This comes not a moment too soon — next week is a jaunt to Lisa’s old stomping grounds across the Pond before I switch full-time to console fabrication and systems design with an eye toward the Perl Whirl launch in the Inside Passage next June. Between now and Sunday, I need to spend some Time On Water… a quick Puget Sound loop that’s a miniature of the Previews of Coming Attractions tour I’ve been planning.

Damn, what a mad epoch we’ve been going through. All publishing and domestic projects were pushed aside to make room for mission-critical fabrication jobs: finishing the myriad landing gear parts, hydraulic rudder controls, pedal drive deployment scheme, bedding and bonding deck fixtures, hydration system, dodger fixtures, windshield, temporary power distribution and GPS/VHF mounts, and enough other essentials to make this wee boatlet feel like a full-scale yacht (at least until she’s put into scale by her first big seas). And ya know what I’ve learned?

The Roberts Law of Creeping TO-DO List Complexity: The time required to complete a task is inversely proportional to the number of words required to express it.

-Steven K. Roberts

We’ve spent weeks working on components so minor in the grand vision of things that they disappear into single TO-DO list line items or (in many cases) never made it onto a list at all. It’s reminiscent of programming: as you wend your way from a notion of what you want the machine to do to a precise definition of how it should go about it, minor tasks labeled TBDWL (To Be Dealt With Later) and ATAMO (And Then A Miracle Occurs) suddenly seize center stage and are revealed in the full glory of their unanticipated complexity. And that’s where you spend your time.

All this will doubtless be remembered as a vague nightmare someday; for now, I’m happy to report that this crazy canoe is off the epoxy-encrusted workstand and poised to take on a life of her own.

Why Boats Don’t Have Wheels

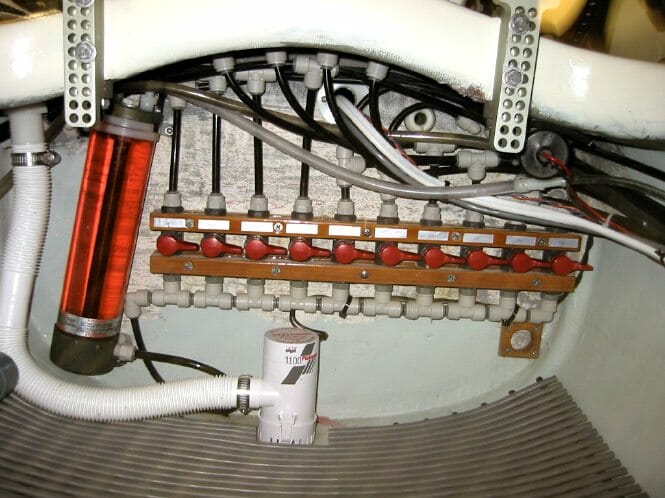

I described the general design of the landing gear system in Issue #130, freshly stunned by the realization that the front wheels need active steering to handle the non-vertical castering axis imposed by packaging constraints (it worked fine rolling forward, but nobody thought about reverse). Actually pulling this off without compromising the elastomeric suspension and retraction capability occupied most of the time since our last report, involving dozens of custom parts and esoteric hydraulic hacks. Including the rudder system, the boat has a total of 13 Clippard cylinders, about 180 feet of nylon tubing, 12 valves, and over $300 worth of fittings. We bought 16 bottles of baby oil at a local pharmacy (approximately SAE 5 mineral oil), but are doing initial tests with water — selecting a working fluid has been a project in itself, with the need to juggle trade-offs of toxicity, odor, viscosity coefficient, lubricity, thermal expansion, ease of clean-up, freeze-proofing, chemical compatibility, and availability while traveling.

(I might add that the process of filling the hydraulic system and getting the air out is nasty: after trying with vacuum and localized bleeding hacks, we finally discovered that every cylinder has to be removed, submerged and cycled a dozen or so times, and then reinstalled while fluid is actively flowing out of the lines under pressure and splashing on the floor. This is not fun, and would be even less so with baby oil in a fiberglass shop unless you’re some kind of sicko who ENJOYS such abuse.) [Later note: this was eventually fixed with NPT bleeder ports tapped into spot-faced flats on the cylinder ends, making it easy.]

The whole thing sounds gratuitously weird, but this landing gear problem is a critical one: if you’ve been with us for a while, you know that the Microship project calls for open-ended travel in a boat that’s larger than a kayak but smaller than a yacht. Kayaks and canoes can be hauled out, but are too small to support multimode propulsion, graphic interfaces, and huge solar arrays; yachts allow a live-aboard lifestyle, but don’t even begin to fit the aesthetics of our mission profile (and the bigger they are, the more costly are haulouts and slips). Without resorting to the nautical equivalent of a sag wagon, anything in between is stuck in the daysailer category.

Unless, of course, the boat can sprout wheels on demand and roll up any convenient beach or ramp… whereupon it straddles the disparate worlds of kayaking and yachting with the benefits of both and the disadvantages of neither.

We’ve managed to find two solutions to the problem, the first (and unmistakably geekier) of which is now implemented on my boat. Lisa looks upon this with justifiable horror, recoiling from the cost and time that would be involved in cloning and maintaining it — she’ll opt for the low-tech approach of schlepping wheels and frame parts to shore, assembling a noodly trailer, retrieving the boat, and lashing it down solidly to create a triangulated structure. Meanwhile, I’ll just pull four levers, hit the beach at up to 4G shock load, vault manfully off the bow without getting my feet wet, and haul on the towing harness to effect the transformation to land vehicle. The most brutal part of this whole project is that many months of work were necessary just to get the chance to reality-check the concept. <shudder>

Those levers are a kick, by the way. After discarding about a dozen alternative ideas, we decided to allow the four landing gear to swing freely, handling the transition between extended and retracted states with lines managed by levers on the gunwales, each of which takes care of uphaul or downhaul for the two wheels on the corresponding side. The uphaul levers are also coupled to hydraulic cylinders to effect a 75-degree front wheel rotation from stowed to extended mode.

As with most of the projects, this simple idea (sketched in a few minutes) unfolded into a panoply of fiber-snapping stresses, buildups for block mounting, line interference and chafe problems, material choices, steering geometry learning curves, and countless glitches that each require a bit of machining, TIG welding, component modification, or glasswork. But as mad at it looks, it does work — although reverse is STILL fragile. I’m learning how to calibrate the whole mess: the levers have been drilled with a staggered hole pattern that accepts a lockstitch of the deployment lines, with “gain and offset” adjustments provided by hole choice and line length, respectively. The 2.4% stretch of braided polyester (at 15% breaking load) makes the rigging forgiving but is sloppy on the road… I just ordered some unidirectional Vectran-cored stuff that should be better.

[Later note: that was discarded as well, and replaced by jacketed stainless cable tensioned with turnbuckles… which worked perfectly. My friend Dave Aton contributed some fine doggerel in response to a 2006 Facebook post about all this, and that led to the following exchange.]

To suitable points on the pivoting struts,

The jacketed cables are tensioned,

By turnbuckles, pulleys, lock washers, and nuts;

A nice bit of work, as I mentioned.

-DRA, Feb 2006

“Twill be but a month,” quoth I to my mate,

As I started designing the system.

But gotchas and oh-shits soon filled up my plate…

And all of the deadlines? I missed ’em.

-SKR, Feb 2006

Twixt burnishing whatnots and . . . Heaven forfend!

I feel like I am the proverbial

Wallpaper applier, whose project lists tend

To extremes — some might say to hyperbial.

-DRA, Mar 2006

The years they blew by while my hair turned to gray…

But still in the lab did I putter.

When friends came to visit, “oh wow!” would they say,

While “no way in hell” did they mutter.

-SKR, Mar 2006

As our rabbits had litters that grew to gray hares,

And the earth traveled ten times its orbit,

This landlubber life became work more than play,

And I yearned for the seafaring tar bit.

-DRA, Mar 2006

Anyway, all this runs through 18 Ronstan blocks bonded to the hull, each tweaked to the optimum angle with a faired buildup of glassed-over hard fill, interfaced with the skins for optimum stress distribution, and potted in between with syringe-injected fibrous epoxy. This is how we spend our nights around here… suiting up around 2 AM and working until 4:30 or so in order to make sure there’s goo hardening while we’re off at the house, wasting time with sleep.

Hydraulic Rudder and Spinfin Deployment

While all this was going on, I redesigned the rudder system — the “sliding armrest” scheme I reported on so proudly is now a collection of junk-box parts, some already recycled into other components. That approach, while kind of sleek, was a serviceability problem and generally too fragile. The new one is not only much better, but DONE.

What we have now is a pair of fish-mouthed T handles, pivoting in aluminum underdeck mounted cages on shoulder bolts with Delrin bearing inserts. The deck is opened and shaped to accommodate the travel, and there’s lots of room for later addition of controls when all this mechanical stuff moves to the background.

At the bottom of the arm is another bearing, to which is attached a stainless rod end on a 6″ hydraulic cylinder that pivots off another underdeck fitting. And that’s about it: two runs of nylon tubing from each side wander off, tee into the calibration valve manifold on the aft bulkhead, and end up at the stern to drive the cylinders coupled to the rudder yoke. It’s easy, clean, rugged, and exposed for service.

But there was another rudder problem that had to be solved before that could be crossed off the list… deployment. As with most things, this seemingly simple problem conceals nontrivial issues: I need a handle to retract and extend the rudder, but when down it must kick up without damage if I stupidly plow into something. It also has to be easy to decouple the uphaul linkage and fold the rudder over onto the deck for land transport and tight storage.

Enter hydraulics once again. A pair of cylinders, back to back, comprise the circuit; the control end is just a foam-grip handle bolted to the rod. This pivots axially as well as moving linearly, allowing me to engage a hard hold-up latch, a “floating deployed” mode which allows zero-stress kickup for thin water, and a standard deployed mode with a spring-loaded latch tunable to some magic release pressure that’s yet undetermined. At the business end, the cylinder rod and rudder deployment arm carry custom aluminum hinge parts linked by a tethered faspin.

But everything that protrudes downward from a boat is a potential disaster… what happens when you’re flying through shoal waters without paying attention to the depth sounder and whack the bottom? More than one daggerboard has turned into a cleaver, slicing up through somebody’s hull as their boat plows relentlessly over a rock. In the Microships, we have daggerboards, rudders, pedal drive units, and electric thrusters poking down at various times, and all of them must fail in predictable ways.

Bob Stuart’s SpinFin pivots down from the starboard side, a slim blade with a 13″ propeller driven (at 10X cadence) by pedal power. It’s designed for all anticipated stresses including abrupt backpedaling, but all bets are off in a grounding. We were fortunate to have a visit recently from Conrad Oho, and he solved it beautifully.

Basically, there’s an internal control handle with a separate thru-hull bearing, coupled to the drive unit casing via an external arm and linkage. Inside the end of the handle is an expanding rubber fixture, supporting an elegant machined latch assembly that engages a receiver glassed into a hull buildup. In normal use, pulling a string against light elastic tension releases the latch, and it locks in the up or down position with a satisfying little ‘snick.’ But in a grounding, when the control handle tip load exceeds an adjustable setpoint of about 60 pounds, the whole latch assembly rotates and decouples itself from the receiver plate.

What’s amusing about this is not only Conrad’s clean design, but also the recycling that took place. The handle is an old Winnebiko handlebar with 16,000 miles of road history, the expanding rubber fixture is a drum-sander mandrel, the elastic is a woman’s hair band, the aluminum is Silicon Valley surplus from David Berkstresser’s basement, and the latch linkage is a tip rod from a Hustler mobile ham antenna!

System Updates Various

The combination of a big deadline push and a long interval between postings leaves us with news in a lot of areas in addition to the major projects described above. Here are a few quick updates….

- Dodger Project: Ah, this is wonderful. Mary Davis, a fabrics guru here on Camano Island, has almost finished sewing the Microship’s “convertible top” from a batch of goodies donated by Sailrite: beautiful red Sunbrella fabric, clear window material, netting, zippers, and nifty slide-in fastening rails reminiscent of mast boltropes. I used boiling water to shape the rails and Lisa filleted them onto the arch; Bob finished both the aluminum windshield frame and a pivoting bail to support the aft segment of the fabric. This will be a key tool in these Northwest waters, providing harsh-environment protection with lots of window space and screening… and it’s stunning, reminiscent of ragtop aircraft. If you want a first-class piece of fabrics engineering, let me know and I’ll put you in touch.

- Anodizing: For years, aluminum anodizing has been one of those mysterious and expensive processes that require sending precious parts out to strangers. But with a bit of phone coaching by David Berkstresser and a couple of corroborating websites, I recently found that the basic process is no big deal. All it takes is a bucket o’ battery acid, a 12-volt power supply, a current meter, a cathode of aluminum wire and foil, and a copper wire from which dangle the parts being processed. A pre-wash of dilute nitric acid is recommended, then you let the current flow for 20 minutes or so and boil the parts in distilled water to passivate the surface. Want color? Soak it in a cold solution of RIT dye for a while before the boiling step. Don’t try this at home, etc….

- Microship Water Works: OK, maybe this is a little excessive for a canoe, but I bet it becomes an indispensable part of life afloat. Water bottles and cages are so… pedestrian, you know… and besides, it’s a lot of handling hassle. So the boat now has running water: I swiped the “Book Bottle” 7-liter rectangular Nalgene tank from BEHEMOTH’s helmet-cooling system, fashioned a wooden hangar to match the handle, and used a Bungee clipped to a pair of glassed-on eyebolts to keep it from slapping the hull. Some FDA-certified potable water tubing runs from a quick-release tank fitting to a 1 GPM Shurflo pump, and thence to a very whizzy little faucet from the same company — a light plastic assembly whose valve incorporates a switch to power up the pump. Simple, yet decadent… I can now sit in the boat and draw a glass of water from the tap.

- Linux Server: The PC-500 board has arrived from Octagon Systems, and it’s now in the hands of Bdale Garbee who is doing the Debian GNU/linux port. We’re currently on a quest for a 32 MB EDO DIMM as well as the largest possible M-systems DOC Disk on Chip (hint), whereupon Bdale will scale the install to fit the hardware environment and write the requisite drivers. This board will become the core of the Microship fleet network, supporting a web server (Mimsy) that is accessible by any on-board console browser or wireless laptop connection. It will also handle environmental data collection, resource management, scheduling and transmission of telemetry blocks, and so on.

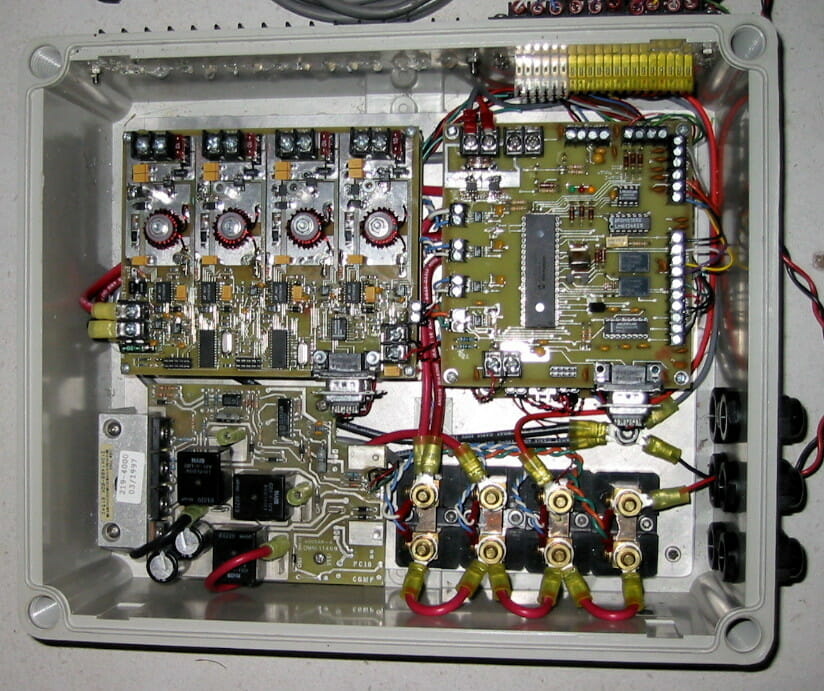

- Power Control: Tim Nolan continues to amaze me — he’s in Wisconsin, building and testing the two 4-channel peak-power-tracker boards that will give our 480-watt solar array an estimated 15% greater net efficiency. We’ve been refining the packaging and connector specs, and he’s planning a return visit to the lab this fall to integrate his boards into the console and fine-tune the thruster control and battery management systems… the photo at right is from a year later, when this was complete. In the meantime, we’re using a Trace C40 solar charge controller for initial testing and will migrate this lovely unit to Lisa’s craft when she’s ready to start lighting things up (her power budget is less critical, so we’re keeping the second system simpler and as much off-the-shelf as possible to maximize the chance of actually finishing it time for launch).

- Solar Array: The folding solar array is finally getting close. We set up a vacuum-bagging facility and tested it on Lisa’s console deck panel; now we’re laying up the substrates that support the 16 Solarex 30-watt ultralite modules. We have the components all kitted: eight panels of 1″ Divinycell foam core material framed with clear fir to handle fastener compression loads at hinges and other fixtures. Tunnels routed in the foam provide wiring channels between the two PV modules per panel, the lines that cross the hinge boundary to its identical mate, and the SeaCon waterproof connectors; embedded nylon tubes guide long locking rods that interface with 3/8″ stainless tapered pins glassed to the hull in a manner reminiscent of old muscle car hood latches. The idea here is that the inner two of the four panels on each side can be folded over to expose a nonskid path to the dock, while providing access to the outboard landing gear deployment levers. At the ama end, the panels will rest on a long rail, held down by bungees to allow the whole system to flex in waves without damage.

- Nav/comm and Location Tracking for Test Tour: The upcoming Puget Sound test has become shorter and more spartan as we’ve crunched the schedule from both ends, and now we’re only a day away. The systems are thus minimal: red and green navlights mounted to the VHF antenna base on a carved bit of clear fir, a white all-round light on the arch, a Garmin GPS 12XL in an off-the-shelf bracket, and Standard’s Intrepid DSC-capable VHF. Bill Vodall was here last week and did a great Pelican-box repackaging of my APRS/packet system, so we will also have live position telemetry during the tour.

Roll the Credits

I am endlessly delighted and grateful for the first-class support this project receives from all over. In the past 3 months, we’ve amassed quite a roster of new thank-you’s. In addition to the various folks credited in the foregoing and the always-indispensable wizardry of Bob Stuart, we extend our deep appreciation to:

- Ed Roberts, my father, for his periodic donations that help so much to keep this project afloat through long dry spells between speaking gigs and magazine articles

- Dave and Holly Sprague for their generous donation to the project

- Mike Setzer for the constantly useful hand-me-down Ryobi jigsaw

- John Samaras for help on cleaning up the landing gear scissors and fabricating the anchor nest

- Halted Specialties in Santa Clara for BEHEMOTH crate storage

- The TIG Shop for good deals on welding

- Lonnie Gamble for building the hot tub deck

- Dave Wright for putting the hot tub parts together and firing ‘er up (this thing has already changed our lives — it’s the perfect decompression tool and back-fixer after a brutal night of boat work, of which there have been many.)

- Composite Materials for a lifesaving batch of epoxy

- Aquarian Audio for hydrophone sponsorship

- Trace Engineering for the C40 solar charge controller

- Octagon Systems for the PC-500 single-board computer

- Sailrite for fabric sponsorship… these folks have a great catalog of do-it-yourself sails, biminis, covers, and other nautical fabric projects

- McMaster-Carr, not a sponsor, alas, but the ultimate one-stop hardware store with unbelievably fast service

- Captain Craig for languid Lake Union cruises aboard Sunbeam, a classic 1929 wooden motoryacht

- Our rapidly growing family of Camano Island friends, who are making this a home worth coming back to.

I’d also like to thank Lisa, my pal, who is slaving away on glassing the second boat (we still don’t know if these are to be named Delta and Wye, Io and Europa, or Caster and Bollocks). She’s amassing learning curves at every turn, and spends her time slinging epoxy, laying out publications, drawing, doing the books, editing video, sending photos to the media, pampering Java the cat, and sleuthing through nettles to find the hidden nests of our chickens (many are culled, but few are frozen). Hard to believe we’re going on 2.5 years already…

Oboy. The next time you hear from me, it should be with news of adventure and a completely different perspective on the project. I can’t wait.

Cheers from the nomadhouse!

Steve