Kayak Stands

This is almost trivially simple and can be done with endless variations, but I’m posting it to help prevent any more “consumer moments” than necessary. You can buy things like this on Amazon, but it’s a fast project that can be accomplished with mesh slings, some PVC from the local building supply store, and an hour or two of time.

Easy Homebrew Kayak Stands

© 2010 by Steven K. Roberts

Nomadic Research Labs

There are lots of good reasons to keep kayaks off the ground… including general boat hygiene, keeping rodents and spiders from nesting in them, speeding the washing and drying process, raising them to a working height that’s easy on your back, and expanding available storage space by opening the area beneath the boat. This little trick is a lightweight solution to the problem, and can be scaled to whatever height and width needed.

I used 3/4-inch Schedule 40 PVC for these, and it has been quite adequate. I wouldn’t quite trust them with body weight, but that’s not the intent… it just keeps my boatlets off the eternally moist concrete floor or muddy lawn. The units shown here are made from the following components… quantities shown are for a pair of stands, good for one kayak:

- 8 PVC vertical members, 24″ long

- 8 PVC horizontal members, 13″ long

- 16 PVC 90° elbows

- PVC cement (not necessary but recommended for maximum toughness)

- 4 bolts, 2.5″ long 1/4-20 with lock nuts (either 2 regulars jammed, or one nylock).

- 4 washers (1/4″) washers between the tubes – good form but not really necessary

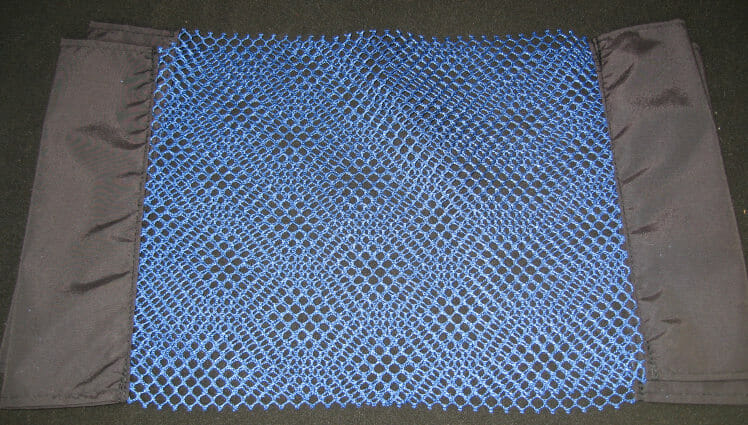

- 2 Fabric slings, approximately 10×17 inches with sewn-in tunnels.

All this is non-critical dimensionally. If you want it taller or shorter, just adapt the vertical members accordingly… if you want the stands to be a little stiffer and heavier, you can upgrade to 1″ PVC. The pivot point is midway down each long tube, and is easily drilled with a 1/4-inch bit (if you’re free-handing, you will get more accurate results by drilling a smaller pilot hole first). You can glue them with PVC cement if you want them as tough as possible, though I find it more convenient to just press the fittings on… it’s plenty strong and you can break them down if you ever need to.

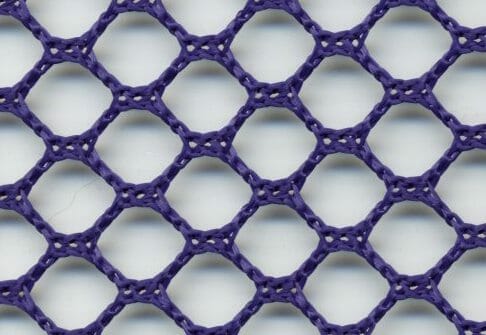

The important part is the fabric saddle; I recommend a strong synthetic mesh instead of a densely woven cloth that will hold moisture against the hull and cause mold:

You could use simple web straps and slide-release buckles (or, I suppose, even rope) instead of the somewhat more complex sewn tunnel shown in the photos, but I would advise caution with this… not only are there moisture-retention issues, but some hull materials like rotomolded polyethylene will take a “set” if stress is concentrated in a small area over time, especially in hot weather. After considerable experimentation, we settled on a strong mesh that has held up over 5 years of use without any sign of degradation from the evils of ultraviolet, moisture, and stress:

This is, in principle, a simple home project – the total cost of the PVC parts for each stand assembly is only about $8.00. The slings are a bit trickier, as sewing an open-weave mesh requires careful handling.

Feel free to copy the concept… for a few years we were selling the slings, but stopped in late 2018. You can clone these with mesh as shown in the photos, or create similar functionality with loops of nylon webbing fixed with an adjustable buckle, or even a few turns of soft rope (just use enough to distribute the load to prevent rotomolded hulls taking a set in very hot weather).

As with all fabrics, long-term ultraviolet exposure is the enemy and will eventually cause failure… so parking them in the sun forever is not advised. If you can tarp it over, both your slings AND your kayak will last longer.

Here are a few photos of the units in use:

Cheers from Nomadic Research Labs!

Steve

Great idea to use the classic sling or directors chair design for a stand.

Now, maybe you could come up with an idea for a way to hang the kayak from a wall so as to not have anything touching the grass!!!

With the stands we still have to go around them with the power mower… grass gets everywhere, dirt, leaves… a mess!

Thanks,

Lorraine

Hmmm… I haven’t tried it, but with a mix of pipe clamps and a little additional PVC, it might be possible to adapt the same stands. Picture the X up against a wall. If the top rail were attached with a couple of pipe clamps (ideally by changing the corner elbows to tees, so the clamps don’t “scrunch up” the sling tunnels), and the two legs likewise are attached by using elbows to create a connecting tube, then it should work (though would not be self-adjusting except for the mesh stretch. Worth the experiment!

Cheers,

Steve

I’m thinking about mounting the stands on a 2×4 platform with a set of wheels from my old lawn mower so I can move it while on the stand.

Good idea, Terry!

-Steve

If Are you selling the mesh? Why not a complete stand.

thanks

Hi Tom, and thanks for the inquiry! Complete stands, once packed for shipment (even if unassembled), would cost more in postage than the value of the actual PVC material. But the question does come up every few months, and I’m starting to think seriously of doing a full kit that includes the slings, cut and drilled PVC, hardware, added pipe insulation for the top, and instructions. If you’d like to be our first victim, please let me know and I’ll come up with a price. We’ve heard from a few folks who live in big cities where it’s kind of hard to get big-box-store hardware like this, so it probably makes sense.

Cheers!

Steve

Looks like the mesh slings can accommodate a larger diameter pvc pipe. How big can you go on the pipe? You used 3/4. The pictures show a larger opening in the sling tunnel. How big a diameter on the pvc can you go? Thank you.

Ken Zaback

PS: I just purchased the mesh sling

Hi, and thanks for the order! The tunnels can accommodate 1.5″ diameter (tightest at the ends where the additional stitching is). This translates into 1″ NPT being fine, and that will definitely make for a stiffer stand than the 3/4″ stuff. The 1″ Schedule 40 PVC has an outside diameter of 1.315″