Bikelab Report #3 – Solar Power and Battery Babysitting

The bikelab series was starting to hit its stride, and this issue focuses on the BEHEMOTH power system… a huge and central part of the project. As with the others, this text languished for decades in a dark corner of my site, with no images to shed any light on what I was talking about. Let’s fix that.

Bikelab Notes #3

December 30, 1990

©1990 by Steven K. Roberts

ALERT: Don’t take the density of aluminum for granite! It’s tempting to throw unlimited aluminum at a project, thinking it light… but its density is almost identical to that of granite: 2.64 versus the rock’s 2.69. A cubic foot of aluminum weighs 165 pounds; of granite, 168. Bike parts, eh?

Project Update

Two weeks have passed. Most of you took off for the holidays — the email and phone have been eerily quiet. What have I done with this surplus of time?

Hm. One thing about a system this complex is that apparently trivial components — the ones we take for granted — end up monopolizing huge blocks of time. Considering the fact that it’s MY time we’re talking about here, that 29 weeks left until departure is already feeling like quite a squeeze. I did learn something useful about that during a recent visit to Trimble Navigation, though: admiring the project organization represented by a giant D-size PERT chart, I complained that when I tried to use InstaPlan for similar purposes, it just turned into an intimidating graphic linear TO-DO list.

“Project management tools assign resources to tasks,” an engineer told me. “In your case, since you’re the only resource, it doesn’t make any difference what you work on. Just DO something!”

This obvious little bit of advice changed my life. Duly inspired, I hustled back to the lab and got to work… spending the last couple of weeks on gasket-compressing latches and manpack tie-downs for the RUMP lid, OrCAD PCB software installation, Lemo environmental connector specification, the IBC BoardMaker learning curve, setting up the bike’s new MIDI system, testing commercial audio amplifier modules with the intent of finding low quiescent power drain, probing the myriad trade-offs of battery charger design, working on the multi-platform SCSI bus architecture, and trying to get my body in shape with weights and a new sweat machine. Presumably, all these except for the last one will eventually find their way into articles here, so let’s get on with the mail…

The Emailbag

From Dave Webb at Tektronix:

Steve Sergeant and I were discussing your plans for vertical handgrips in the steering of your recumbent, as an alternative to the conventional horizontal steering bar. Riding frequently in the Oregon rain, I occasionally use the steering bar to pull my bike (a lightly modified Infinity recumbent) back underneath me when recovering from skids. Is your vertical handgrip position in danger of compromising your ability for skid recovery?

Since one can’t effectively lift one’s ass from the seat on a recumbent when trying to recover from a skid, the steering bar serves both to lever the bike into a more vertical position, and to help slide oneself sideways on the seat, allowing the bike to remain vertical if one has reacted quickly enough. It seems that being able to lift oneself by the hands plays a part in these actions. I don’t have good data on this, because I don’t intentionally put myself into skids for experimental reasons. However, it is fairly easy to get the Infinity into a skid, because there is very little weight on the front wheel. I’ve collapsed a steering bar once doing this. The steering cables become much more like horse’s reins when this happens. The cable to the unbroken side of the steering bar still worked (in tension, of course), and by leaning the bike to the other side, I was able to keep the usable cable in tension until the bike could be stopped. After this incident, Infinity doubled the wall thickness of their steering bars.

Another consideration in steering bar design is the effect of sideswiping, or being sideswiped by another vehicle. The steering bar is the widest part on my bike, and is vulnerable to this. Perhaps this is less of a threat to your new design. Please let me know the details.

Thanks for your thoughts on the steering… I’ve pondered and worried about it myself. Original motive of the new design is to increase typing/flute-playing speed, and the configuration evolved from lots of thoughts about what happens when it falls over, where the grips hit, etc. My one lingering concern is the movement of my body on steep climbs… might need a 5-point harness to prevent wasting energy! 🙂

I haven’t had much experience with skids… very rare on a megacycle like this. I’m trying to remember times when I put substantial force on the bars, and I honestly can’t (with the possible exception of pulling when hill climbing to lock myself into the seat). But width is an issue — on a narrow Florida bridge once, my right shifter hit the back of a guy fishing, not only infuriating him and nearly causing an incident, but also driving me into the concrete wall and nearly wiping me out. Narrower profile would be nice, especially in wrecks: the new steering hardware will be protected by small cages TIG-welded to the seat frame.

I’ve always been a trifle uneasy about cables… they appear to offer an easier design solution that’s nicely tweakable, but are quite limiting structurally. The system has to be perfectly aligned for them to work properly, and is generally non-deterministic. But the Infinity did feel pretty good to ride (Maggie had one during our trip down the west coast).

I guess the real test of the new steering geometry is to just try it. I know the human interface issues will be much improved (just having the thumb free to wander over a small panel and reducing internal tendon friction by removing the wrist twist make a huge difference in output data rate). I’ll report on what happens… the mechanical design is done and my machinist and I are chasing parts….

Solar Power and Battery Babysitting

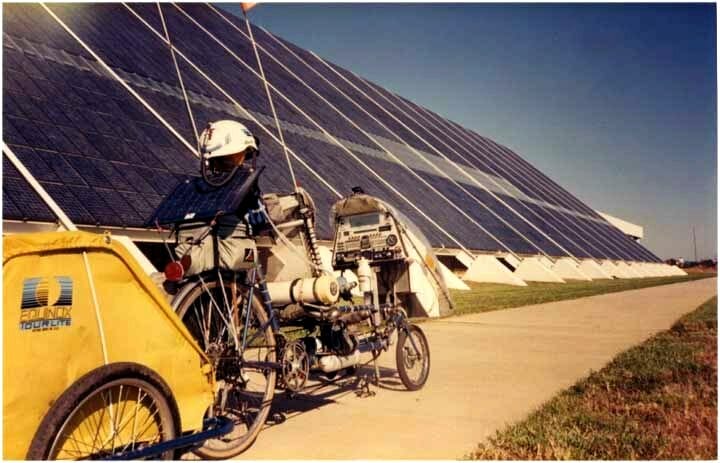

This is a critically important part of BEHEMOTH — the primary power source for everything except the wheels. (Actually, they are solar-powered too, if you want to get philosophical about it… I am part of the food chain, after all…)

From the very beginning of this adventure back in 1983, I have depended on photovoltaics. The original Winnebiko carried a small 5-watt Solarex panel that charged a 4 amp-hour SAFT NiCad pack — about right for the Model 100 laptop, UNGO box, CB, and basic lights. The Winnebiko 2, on the road from 1986-88, had a pair of 10-watt panels (a lighter, newer Solarex design) and a pair of the same NiCads, later replaced with 10 amp-hours of Gates lead-acids to simplify management. There were correspondingly more loads, of course, and the batteries were attached to two swappable buses to provide redundancy and improved noise isolation. And the new system is up to 82 watts of PV’s, with 49 amp-hours of main system batteries as well as a few others scattered here and there as required by particularly picky subsystems, all managed by FORTH tasks linked to extensive data collection and power-steering logic. Ah, bike parts.

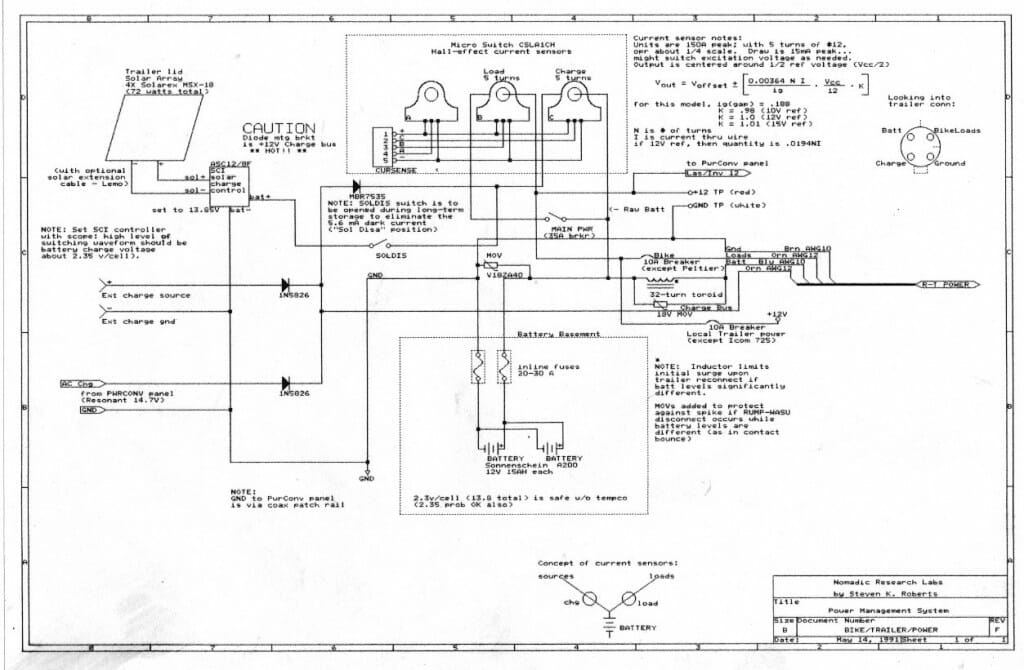

First, the big picture: there are three 15 amp-hour Sonnenschein Dryfit A200 series batteries (12 pounds each <grimace>) aboard BEHEMOTH, two in the WASU (wheeled auxiliary storage unit) and one in the RUMP. Electrically, they appear as one big battery, and some switching logic at the trailer-disconnect header lets the bike power bus continue uninterrupted if I go somewhere without my WASU. This main battery has four charge sources:

The 72-watt photovoltaic array that is the trailer lid, made up of four Solarex MSX-18 modules (each is about 17×19″ overall, with 14×18″ active area). Parallelled, these collectively produce about 4.8 amps into the 12-volt battery in full sun, and are simply passed through a Schottky diode into the charge bus.

A 10-amp line-operated switching supply from Resonant Power Technology, likewise diode-isolated. This efficient transformerless unit is only 1.5x3x6″ and has a jumper for 110 or 220 volt input.

The regenerative braking controller, still under construction, based on a .5-horsepower 3-phase Semifusion variable-reluctance motor-generator that is the hub of the new front wheel. A dedicated microprocessor controls this, and will extract power from the bike’s momentum as a function of right-hand brake lever compression up to the point at which the hydraulics engage. (Don’t email me for details on this… let me get it working first!)

An external cable intended to plug into the cigarette lighter of a motor vehicle, to let me “jump start” on cloudy days away from power lines when I’m not moving.

Battery management takes place in two layers. The first works whether processors are alive or not, since basing the health of such a fundamental system upon working software is dangerous indeed. This is in transition (I’m currently testing competing products), but here’s the basic idea: a basic off-the-shelf solar charge controller intervenes when it thinks the batteries are full and does something to divert the incoming power. My first pass was with a pair of Sonnenschein SR-50 regulators, matched to the batteries and thermally linked to them via a thermistor. The concept is simple: terminal voltage reaches 2.3 volts/cell plus/minus tempco effect, and the two-terminal unit gets hot, shunting excess power into its finned radiator.

Despite the apparent waste of this approach, it makes sense, and I integrated them into a larger system that uses hall-effect current sensors to monitor total charge current, total load current, and current discarded by the regulators. This allows the processor, if alive, to notice that power is being tossed and switch on an optional load, like the Peltier refrigerator. But I ran into a problem — the SR-50 is a 50 watt unit, so I had to parallel two of them. No two things electronic are ever perfectly matched, so in full sun at full charge, one would get hot and go into thermal shutdown, the next would quickly follow suit, then the batteries would take all the abuse of overcharge. No good.

Last week I installed a new ASC unit from Specialty Concepts. This is designed to intelligently track battery level, use pulse charging for increased efficiency, and protect the battery against overcharge by safely shorting the solar panels (it is a 4-terminal device). The concept and execution are good and it works, but I objected to the 10mA or so of “dark current” that it drew from the battery when no charging was taking place. I isolated it with a schottky diode, and since its sense line was no longer on the big “capacitor” of the battery, it went into an interesting 2.2 kHz oscillation that still seemed to charge effectively but no longer let me adjust the setpoint to anything predictable. (There was also some noise on the power bus that could be heard in the HF rig.)

This note was added in the next issue (1/6/91):

Thinking again, I’ve decided to stick with the SCI (the Automatic Sequencing Controller from Specialty Concepts — The dark current is 5.6 mA, which will kill my batteries in about 8,000 hours of dark storage (assuming a perfect world, lumped constants, and no self-discharge…). The unit is actually quite clever, and the fix for the oscillation was to simply eliminate the schottky diode and let it sit on the battery bus where it belongs. It now switches neatly and quietly, harmlessly shorting the solar panels when the battery is at or above setpoint (and it doesn’t care about the presence of other charge sources).

So now we’re back to square one — an obvious approach is to let the trailer-control processor simply do what it wants to do anyway: disconnect the charge sources with big FETs whenever the batteries are full (adding hysteresis to keep oscillation under control). But for simplicity and reliability, I’m still seeking a standalone dumb controller that can do the job even when computers are down, probably a larger version of the original shunt regulator. <sigh> Nothing is ever trivial.

By the way, the choice of solar panels was a deliberate one. There are many to choose from, from heavy glass-covered units ideal for permanent installations to the flexible and much-publicized Sovonics flexible amorphous models. The former are too bulky; the latter are too inefficient (and amorphous panels degrade at the rate of about 10-15% per year for the first 2-3 years of service, yielding a net output per unit area of about half that of silicon). Of course, dollars/watt is a different story entirely, but the bike is more like the space program than a homestead… I want the best performance available, and hang the expense (well, there are Gallium-Arsenide space-grade cells that run about 22% efficient, but they are VERY expensive). The solution was the Solarex MSX series, sold heavily in the marine market and robust enough to be walked on if laminated into a boat deck. Backing is aluminum, and the silicon semicrystalline chips are sealed in Tedlar — overall thickness about .1 inch. They have no frame — just four grommeted holes for mounting. I’m not sure of prices, but Real Goods carries them retail at [old prices and contact info redacted].

Incidentally, solar panel packaging on a bicycle is not trivial. Any amount of shading (over a few percent) will knock the output to zero — I saw one bicycle at the Solar Expo and Rally in Willits, CA that had a small panel mounted horizontally on the rear rack, almost always shaded at least 30% by seat and rider! Keeping them horizontal is OK — output falls off sinusoidally with the sun’s angle, so steering them for optimum performance costs you more in aerodymic drag and mechanical complexity than it buys you in power. It is good to keep them cool… the worst installation example of all is something I must admit with embarrassment from the Winnebiko II epoch: one of the 10-watt panels was the top surface of my electronics bay… under a clear Zzipper fairing! The greenhouse effect, particularly when the bike was stopped, could quickly elevate the panel — and the electronics within — to 140 degrees F.

The solar trailer lid hinges on one side, using Hartwell quick-release hinges and a Southco E3 vise-action latch. A cannibalized SLIK tripod leg swings down and lets me park the panel at any angle when stopped; and the whole assembly can be removed and cabled to the trailer via an extension cord when I’m camped and the bike is snug inside the porta-condo.

Sharp-eyed readers will have noticed that I mentioned 82 watts of solar power, then talked about the quartet of 18-watt modules on the trailer. There is an additional 10-watt module built into the lid of a Zero Halliburton 103X aluminum case, grafted brilliantly to the curved surface by metal-wizard Ron Covell of Covell Specialty Fabrications. This is the detachable manpack that contains the laptop, RF business-band packet data link to the bike, full-duplex VHF intercom, security components, and so on. I like it to be an autonomous unit, so it has its own 4 amp-hour battery and local management.

I also mentioned other batteries… a quick look at the power distribution scheme might be useful. Generally, the 12-volt bus is distributed everywhere on the bike and spot-regulated locally as needed (in most cases by a little Maxim MAX638-based board designed by Dave Wright). This is much more efficient, quiet, controllable, and fault-tolerant than having centralized DC supplies, and it simplifies dynamic load-shedding when some subsystems are not required.

In the case of some units, however, like the Macintosh Portable, the manufacturer has already done an excellent power-management job that would only be thwarted by my efforts. In these situations, I give the unit what it expects — its own battery (the Mac uses a custom drop-in 6-volt lead-acid pack). The main bus then simply serves as a charge source through a matched DC-to-DC converter.

In a similar vein, there is also a charging station for all the little stuff — the 9.6-volt Makita NiCads (I carry a drill and flashlight that uses them), up to 8 AAs at a time, and so on.

Finally, there is the maintenance issue. Via the Microswitch Hall-effect sensors (model CSLA1CH, very nice), there are A-D converters on the 68HC11 machines that can monitor all relevant currents and voltages — plus little Acculex micropower LCD digital panel meters and associated thumbwheel switches in console, trailer, and manpack. These allow low-level debugging without exploratory surgery if nothing seems to work.

As you can see from all this, power is one of the essential infrastructures of BEHEMOTH, every bit as important as the frame and gearing. The massive amount of apparent overhead yields a robust and dependable substrate that allows new subsystems to be added relatively easily, just by setting device addresses for power switching, serial I/O, audio, and so on. I’ll keep you posted as some of the unimplemented components of the power management system take shape.

You must be logged in to post a comment.