Hogfish Rig Arrival and Wireless Control

Microship Status Report #111

by Steven K. Roberts

Nomadic Research Labs

Santa Clara, California

September 6, 1996

“Nothin’ too strong ever broke.”

— Maine proverb

Rig Arrival And Glasswork

Yikes! This is scary. There is now a 40-foot aluminum mast, with matching 16-foot boom, lying here in the Microship lab, poised for installation. One of the spreaders is attached (a gleaming aft-swept airfoil section), and the Delrin rotation socket is nestled into the base. A masthead halyard sheave is in place, encased in a graceful aluminum enclosure reminiscent of a dorsal fin, and the standing and running rigging are slated for delivery in October. Mike Leneman and friends dropped it off last Friday enroute to the NOOD regatta on SF Bay — rumbling into our parking lot with an F-31 in tow, two gleaming masts lashed across her deck.

This is a major step forward. All we gotta do now is get the boat ready to accept it, then plug it in. Of course, that’s somewhat nontrivial, involving significant design, fiberglass surgery, and eventual rigging. But at least we have begun.

The critical first steps involve the structures that accommodate the mast compression loads, which are variously estimated in the 10-16,000 pound range (plus or minus dynamic loading and not including shear forces). In other words, our first fiberglass project has to be rather robust, and as such we’re involving consultation — Jim Antrim (marine architect), David Berkstresser (mechanical engineer), and Ross Handy (fiberglass maven). Ross is set to arrive Sunday to put it all together, so current work in progress involves drawing the assembly, defining the layup schedule (unidirectional S-glass and 10 oz. cloth in alternate layers), extensive abrasive surface preparation, parts cutout from our stock of ABX marine plywood and clear Douglas Fir, and mast-step fabrication (glass-encapsulated fir sandwiched between layers of ply… all coupled tightly to the bulkhead and existing crossbeam).

Essentially, the goal is to spread out the loads focused at the stainless steel trailer ball that supports the mast in the same transverse plane as the forward folding crossbeams. This involves an amazingly complex interplay of forces, so we’re going for maximum stiffness and interconnection among all the components. Last week I excised the original “manhole cover” mast step, a relic of the original free-standing carbon wing mast built for the original Hogfish by none other than Burt Rutan, and we’re fabricating a wood plug that will serve as a form for restoring the original box-beam structure that keeps the boat from folding in half in response to the substantial righting moments resulting from a 24-foot beam and highly buoyant amas.

As of this moment, we have Jim’s architectural perspective on how best to handle the loads, David has unambiguously detailed the deck/beam surgery, Faun is chasing around Silly Valley on a quest for abrasives, and I’m itching mightily from this afternoon’s bout with the new Makita grinder. (It’s only the beginning… once all our pores are filled with bits of glass fiber, we will lather a coat of thickened epoxy over our entire bodies and never itch again.)

Much more on this soon… it’s a nasty piece of work, but once it’s done we’ll be ready to install the rig and THAT will start to make this feel like a sailboat instead of a funny-shaped enclosure for interesting computer systems.

First Wireless Control!

Speaking of cool electronics, however, there’s been a burst of forward progress in a new direction. Our first attempts at a wireless front-end have borne fruit, helping to define the flavor of the overall Shipnet.

As you probably know from earlier postings, our control network is a multidrop collection of nodes, living under a Hub that handles all communication and presents a unified front end. To date, that front end has consisted of a textual interface in the form of a comm package on one of the development Macs — making it easy to download new code versions and interact with the FORTH interpreter in the Hub (or any node).

This has been perfect for code development, but is obviously not the way we want to run a ship. All along we have been planning to use HyperCard in the console and cockpit Macintoshes as well as those in our manpacks, though the method of smoothly switching the “point of control” via the Sexbar has been a bit unclear. But now it all makes sense: there will be a dedicated Mac associated with the Hub, powered on all the time (some kind of minimal, low-power laptop — no blazing speed needed here). This will serve as a gateway between the serial console port and the ship-wide network (AppleTalk or Ethernet)… one node of which is a Digital Ocean Starfish wireless hub.

And here’s the key link. In addition to the networked Macs (which can now pass around control responsibility without having to play games throwing remote serial switches), each of us will carry a Digital Ocean Tarpon — an Apple Newton embedded in a larger shell that incorporates a 2 Mbps spread-spectrum wireless AppleTalk link. All this is protected by a rubber boot, making this a very rugged and water-resistant unit of just over 3 pounds. In the final system, the Starfish on the boat will drive an external antenna with optional rubber duckies at the manpacks, extending the range substantially.

We’ve been thinking about this for a while, but within the last week two major events occurred: Digital Ocean shipped a Tarpon and Starfish for the development project, and Chris Burmester (a Newton consultant for Apple) wrote some magic code for both ends of the wireless link. At the Mac end, he created a tool called Serial Passage, which uses DILS (Apple’s Desktop Integration Library for the Newton) to implement a pipe between a remote ADSP (AppleTalk) device and the second serial port. At the Newton/Tarpon end, he wrote a simple terminal package with a pen-entry area, a virtual keyboard for those who prefer stylus-typing, and a few basic command buttons (CONNECT, DISCONNECT, SEND MESSAGE). And even though this is still a long way from the layered hierarchy of views we have planned, it is startlingly cool.

Picture this: you’re walking around the lab, holding the Tarpon in one hand, and with the other you write COLORON. Less than a second later, the servo-actuated vane retracts and the color camera springs to life. You write 60 GAZE and the turret rotates the camera to look 60 degrees off zero at the milling machine; you jot TURCOLOR VCR VCONNECT and a picture of Cecil suddenly pops up on the color TV (Cecil be da Mill). As an afterthought, you tell the unit CD SPEAKERS ACONNECT and audio from a jazz CD fills the lab. All this while untethered, even wandering around outdoors.

This low-level wireless command-line interface is the proof-of-concept we’ve been needing — adding clickable icons to eliminate writing those obscure FORTH commands, draggable arrows for setting values, gauges for returned variables, and a graphic hierarchical path through the control network requires only straightforward Newton software based on well-developed, existing tools.

Incidentally, that approximate 1-second latency I mentioned is worth noting… it’s the total of communication events between a succession of 6 processors. The command issued by the Tarpon is transmitted via 915 MHz DSSS to the Starfish hub, which (since we don’t have Ethernet on the venerable SE/30 used for code development) requires a temporary SECOND wireless link to make the transition to AppleTalk (via a Digital Ocean Grouper). From here, it’s but a short network cable to the Mac running Chris’ Serial Passage code, and thence out the modem port at 9600 baud to the New Micros FORTH Hub. There, my nodescan task inhales the message, seizes the network in a friendly sort of way, and retransmits it to the appropriate node, which finally executes the command.

Encouraged by all this, I set to work last night on a first overview of the Microship application that will run in NewtonScript. I’ll tell you more about this as it develops, but basically, launching the app from the Extras drawer will automatically establish the wireless link to the ship (reporting on signal strength, noise level, signal quality, battery level, and Hub-node health). At this point, I’ll have a screen with about a dozen buttons, allowing access to the major subcategories of interface tools:

- Security/Watch

- Position data, chart segments, manpack GPS feeds (APRS)

- Network maintenance tools

- A/V, turret, crossbars, recording devices

- Power/Solar management

- Internal sensors, pressures, fluids, temps, stresses, etc.

- Nav data and thruster controls

- Voice comm systems (SSB, VHF, ham, cellular, GMRS)

- Environmental data collection and hydroponic controls

- Email gateway and net access

In addition, EVERY view in the system will have a small row of icons at the bottom that allow access to the universal tools:

- Alarms and emergency actions

- Text terminal to Hub

- Health screen for entire Shipnet

- Time, temperature, pressure, and other basic data

- Comm link performance, signal strength, local battery

- Reference data and help files (in Newton Book form)

As well as return to the top level.

Naturally, all other Newton resources remain available without breaking the link, allowing message passing and so on. An additional feature will be the ability to direct messages to the Mac, instead of the FORTH network, allowing HyperCard to stay resident in the foreground and allow Tarpon interface with high-level systems, file servers, and so on. (We’ll make the passage code a system extension.)

As you can see, we’re having fun. The 2 years of building low-level tools are finally paying off!

Miscellany & Upcoming La Gig

Finally, we offer our usual collection of random updates.

First, we have a speaking gig in Pasadena coming up on Tuesday, Sept. 24 at the Art Center College of Design. I’ll be there with BEHEMOTH and a current video look at the Microship, starting at 11:30 in the LA Times Media Center. This is part of a lecture series sponsored by Toyota, and should be well-attended.

The Cyberlife filming went very well, and should air soon. Unfortunately, we don’t get cable, so we probably won’t know the air date until after the fact.

I also did a talk a couple of weeks ago for the Silicon Valley FORTH Interest Group — a delightful bunch who made it possible for me to ramble quite happily about the arcane details of the control system without making peoples’ eyes glaze over. It was held at Cogswell College, and just for the pure pleasure of it, I rode BEHEMOTH. Ahhhh yes, I remember… the experience was a delight, and I even fell in with someone at the other end of the power-to-weight spectrum on the way back — a guy riding a Gold Rush replica. Memories of that old on-the-road camaraderie…

Speaking of BEHEMOTH, it’s now looking pretty certain that the bike’s home while we’re on the water will be the Tech Museum of Innovation in San Jose.

Our new lab net connection, sponsored by Zocalo and the famed N0ARY, has been running beautifully for a couple of weeks. We’re now connected 24 hours a day to the vast AppleTalk cloud, and tunnel IP via a dedicated gateway Mac. This is MUCH better than having to dial up, even with the free account and 800 number graciously provided by Qualcomm. I always felt guilty gobbling phone time during those glaze-eyed netsurfing sessions.

And now, the big announcement: It’s time for the Second Annual NRL Electronic Garage Sale! Yes, the floorboards are caving in with the weight of all this merchandise, and the landlord says we gotta move it! I couldn’t stand on my head to give you a better deal, so I think I’ll just sit down over here and rest my back while I tell you about some of the specials… <ahem>

Actually, it’s all in a message I’ll send you if you request it via email, or you can find it on our Web site. Basically, I’ve listed over 50 items I can somehow do without, as well as dozens of books. I want to start now to minimize the amount of stuff that’s going to have to go into storage (where, if electronic, it will lose value anyway). This is a great way to help support the Microship project by helping us turn excess goodies into boat parts… let me know if you want a list of for-sale items via email!

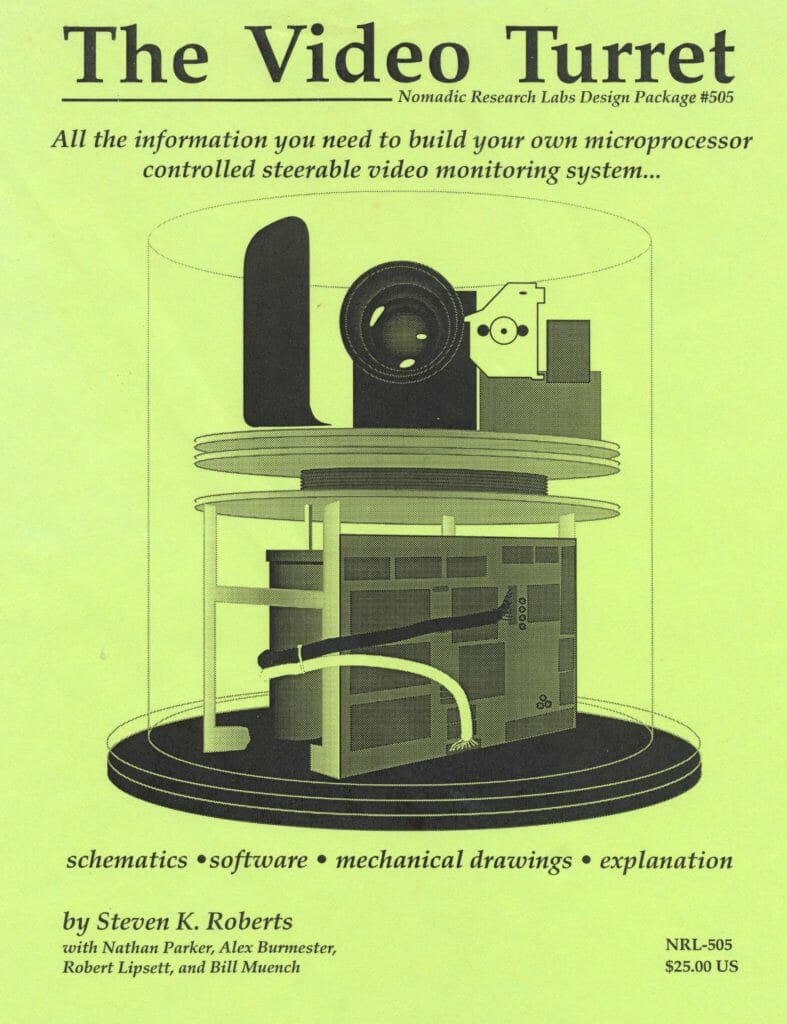

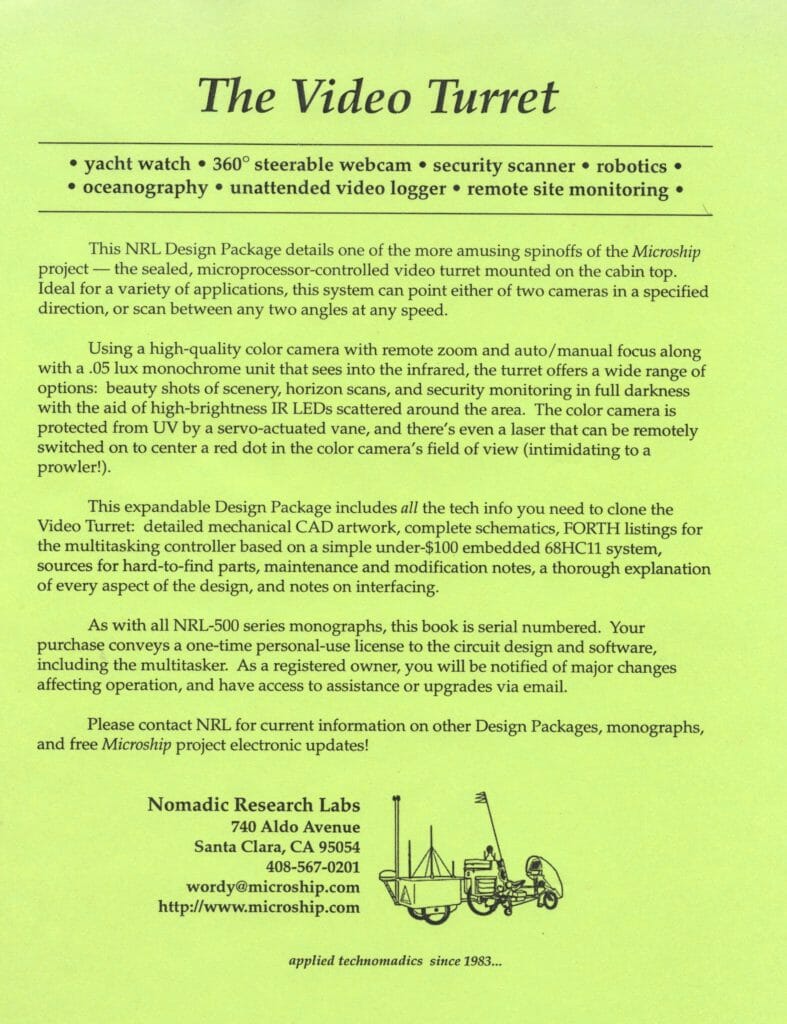

By the way, speaking of things for sale, our first detailed NRL Design Package (NRL-505, The Video Turret, 70+ pages) is slowly making its way into the world… we’ve shipped about a dozen copies. If you want full tech details on the turret, please let me know. And while not slinging fiberglass and hacking FORTH, I’m working on the next one — the complete design of the crossbar networks.

Enough! Back to shaping wood parts for the bulkhead project. I’m feeling guilty… Faun just emerged from the boat, so covered with gray paint dust from sanding that it felt like a sudden reversal of our age difference!

You must be logged in to post a comment.