The Icom IC-725 – 73 Review

by Steven K. Roberts N4RVE

73 Magazine

February, 1990

This is not a normal equipment review. There are no lab test results and no objective comparisons between this unit and anything else on the market. My new ICOM 725 did not arrive with a 73 product-review assignment attached, nor have I really given the issue much thought.

What really counts in equipment discussion is the non-analytical impressionistic view that comes from experience, coupled with some commentary on how appropriate a product is for a given set of needs. And it was a specific need that drove my selection of this unit… bicycle-mobile HF operation.

Battery Operated Rigs

First, I have to say that no current commercial Japanese all-band HF rig is optimized for low-power operation. The two obvious candidates are the ICOM 725 and the Yaesu 747 (which also appears in slightly modified form as the Heath SB-1400). Both are fine units, but they draw a little over an amp on receive standby — far too high for casual all-night use on battery power. Compared to my old Argonaut 515, this astronomical power drain would have an inhibiting effect on operation.

But life is a tyranny of trade-offs. On this next trip, I want more power, more features, more precision, more operating convenience, and remote operation. For all the pleasure of the old Argonaut (and no, I haven’t seen the new model), it’s time to move up. But the inevitable cost is more weight, more power drain, and more complexity. Is it worth it?

Yes!

My ICOM 725 is now shock-mounted in the comm bay of the new bicycle trailer. The 725 offers a serial interface port known as CI-V; this is handled by a local New Micros FORTH 68HC11 in communication with the network up in the console. The radio’s audio input and output are ported to a crossbar switch that lets me conveniently operate with the Setcom helmet headset, a speaker mike, or through the UHF remote — and it’s a simple matter to switch in filters and the like.

Its antenna output is cabled to a coax patch panel through which I can manually select mobile whips, external dipoles, the tuner, or whatever.

Reducing power drain is a little trickier, but I’ve managed an estimated 60-70% savings in standby current. The dial light is now switched, and the internal audio amp is bypassed in favor of the network. And it turns out that you can switch off the power amplifier when in receive with only a slight penalty in T-R delay. I’m rewiring the otherwise seldom-used TRANSMIT push-button for this purpose.

Actually, I may retire the 100 watt power amplifier in the 725. The ICOM engineers thoughtfully made it an easily removable module. The alternative, not available in the US but commonplace in Japan, is a 10 watt amplifier… just about perfect for my lifestyle, and MUCH lighter.

725 Operation

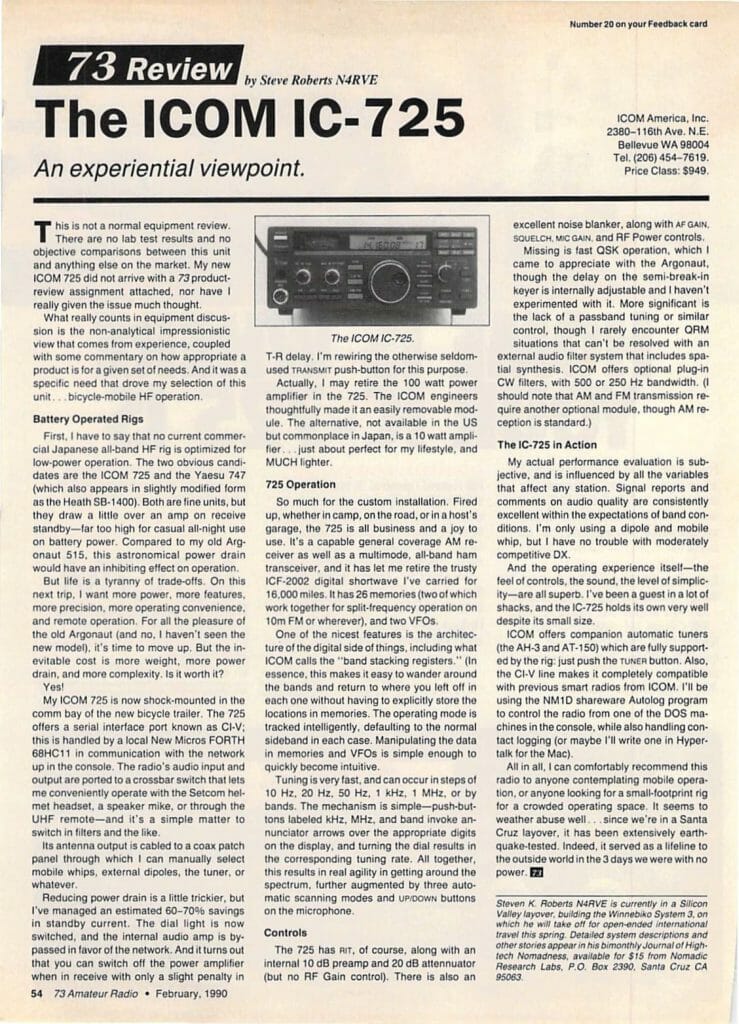

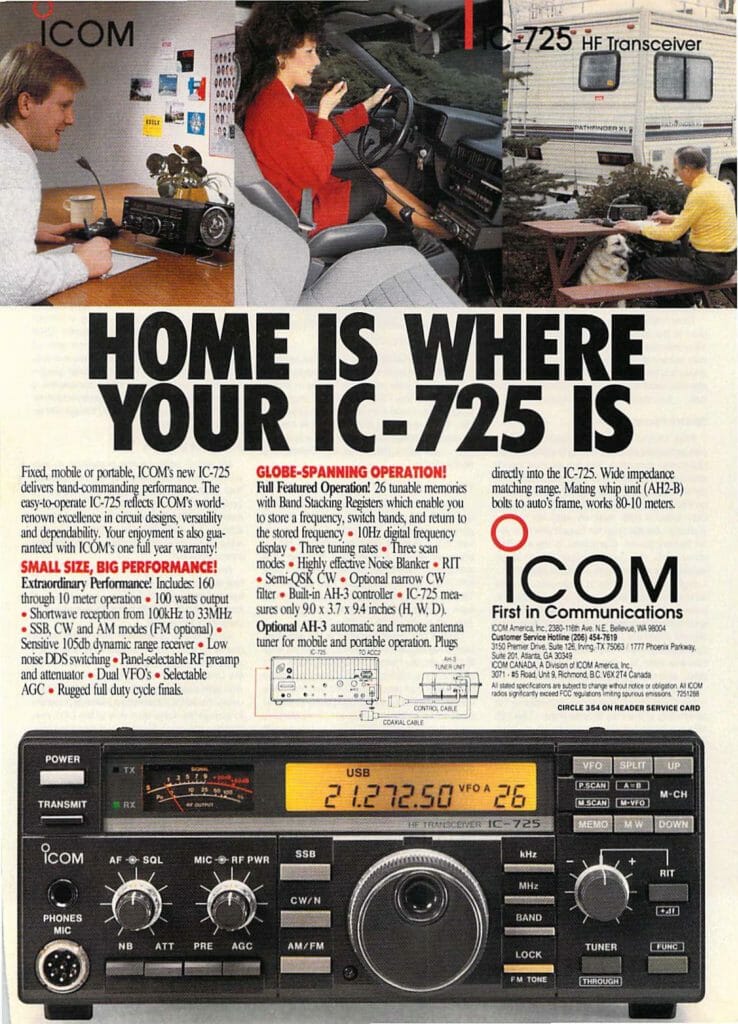

So much for the custom installation. Fired up, whether in camp, on the road, or in a host’s garage, the 725 is all business and a joy to use. It’s a capable general coverage AM receiver as well as a multimode, all-band ham transceiver, and it has let me retire the trusty ICF-2002 digital shortwave I’ve carried for 16,000 miles. It has 26 memories (two of which work together for split-frequency operation on 10m FM or wherever), and two VFOs.

One of the nicest features is the architecture of the digital side of things, including what ICOM calls the “band stacking registers.” (In essence, this makes it easy to wander around the bands and return to where you left off in each one without having to explicitly store the locations in memories.) The operating mode is tracked intelligently, defaulting to the normal sideband in each case. Manipulating the data in memories and VFOs is simple enough to quickly become intuitive.

Tuning is very fast, and can occur in steps of 10 Hz, 20 Hz, 50 Hz, 1 kHz, 1 MHz, or by bands. The mechanism is simple — push-buttons labeled kHz, MHz, and band invoke annunciator arrows over the appropriate digits on the display, and turning the dial results in the corresponding tuning rate. All together, this results in real agility in getting around the spectrum, further augmented by three automatic scanning modes and up/down buttons on the microphone.

Controls

The 725 has RIT, of course, along with an internal 10 dB preamp and 20 dB attenuator (but no RF Gain control). There is also an excellent noise blanker, along with AF GAIN, SQUELCH, MIC GAIN, and RF POWER controls.

Missing is fast QSK operation, which I came to appreciate with the Argonaut, though the delay on the semi-break-in keyer is internally adjustable and I haven’t experimented with it. More significant is the lack of a passband tuning or similar control, though I rarely encounter QRM situations that can’t be resolved with an external audio filter system that includes spatial synthesis. ICOM offers optional plug-in CW filters, with 500 or 250 Hz bandwidth. (I should note that AM and FM transmission require another optional module, though AM reception is standard.)

The IC-725 in Action

My actual performance evaluation is subjective, and is influenced by all the variables that affect any station. Signal reports and comments on audio quality are consistently excellent within the expectations of band conditions. I’m only using a dipole and mobile whip, but I have no trouble with moderately competitive DX.

And the operating experience itself — the feel of controls, the sound, the level of simplicity — are all superb. I’ve been a guest in a lot of shacks, and the IC-725 holds its own very well despite its small size.

ICOM offers companion automatic tuners (the AH-3 and AT-150) which are fully supported by the rig: just push the tuner button. Also, the CI-V line makes it completely compatible with previous smart radios from ICOM. I’ll be using the NM1D shareware Autolog program to control the radio from one of the DOS machines in the console, while also handling contact logging (or maybe I’ll write one in HyperTalk for the Mac).

All in all, I can comfortably recommend this radio to anyone contemplating mobile operation, or anyone looking for a small-footprint rig for a crowded operating space. It seems to weather abuse well… since we’re in a Santa Cruz layover, it has been extensively earthquake-tested. Indeed, it served as a lifeline to the outside world in the 3 days we were with no power.

Steven K. Roberts N4RVE is currently in a Silicon Valley layover, building the Winnebiko System 3, on which he will take off for open-ended international travel this spring. Detailed system descriptions and other stories appear in his bimonthly Journal of High-tech Nomadness.

You must be logged in to post a comment.