Microship Updates – August 1993

At this point, we are only a month or so into the Microship project at UCSD… still putting out “newsletters” as email with my team in the BCC field, the more evolved Status Reports still a few months away. Since there are so many of these, I’m combining them into groups by month. The August 3 post sets the tone, and the rest are below. I have some snippets of video that will be embedded as I get them digitized.

Microship Status 08/05/93

Hey…

Good telcon today with Rich Lehrbaum of Ampro Computers re the PC/104 standard, which emerged from their “Mini-Module” series of embedded PCs (3.6 by 3.8 inch form factor, single +5 supply). Since I used these on BEHEMOTH, over 30 manufacturers have produced compatible products, leading to what Rick calls “object-oriented hardware design.” Off-the-shelf boards exist for data acquisition and control, Sharp color LCD interface, speech I/O, communications, and all the other goodies, and my thinking is that this should be the core of the Microship Control System. It is highly likely that Ampro will continue sponsorship — he was very pleased to hear about my involvement with the ECE department here at UCSD and likes the thought of contributing to engineering education. A care package of info is coming.

Assuming that a PC/104 ROM-based DOS machine is the MCS hub, we now need to select an ultra-low power platform for the autonomous distributed controllers for power management, security, and so on (and decide how much functionality should be distributed and how much handled by the host — a decision driven by such diverse factors as cabling, power budget, project team cooperation, software upgrades, and reliability). A strong candidate for the little guys is the Neuron chip from Echelon, and other possibilities include DS5000’s networked Faddis-style and FORTH 68HC11s on a current loop.

Quickies…

Subscribed to Multihulls Magazine. Requested literature on the Neuron Chips. Began quest for info on commercially available symmetrical trimaran amas that may serve as my main hull.

Good chat with TJ today about the solar-array cooling problem. First issue: is it a problem? If so, other issues arise… is it worth it to try active cooling, like embedding an array of tubes in the layup, bonded to copper sheet underlying the modules, then flowing water through it? If we do that, is the energy cost and weight enough to offset the efficiency increase, and if not, is the improvement in human comfort adequate payoff? Are there long-term reliability issues associated with thermal-cycling an uncooled layup? A project here for someone….

You know, when this is all done, we’re going to have one MONSTER project-presentation party. Imagine the number of participants and the range of interconnected projects, papers, and demos! We should do that on campus, then rumble down to Mission Bay for the launch party and media sendoff. But I’m getting a little ahead of myself. Time to go cut up some cardboard for a cockpit mockup .

Well, I didn’t get quite that far, but TJ scored some fine cardboard and we made a run to Seaweed Canyon to pick up lumber and other raw materials. I moved the Linear Recumbent over to the lab, and we stared at it a while in various stages of disassembly. This could work, but ONLY if it’s a V-hull or something larger than a stock double kayak (CG is too high for kayak, among other issues). After I get a support frame made, the real scope of the problem will emerge when I start shaping the human operating envelope.

The Technomadic Flotilla concept is slowly developing, with 11 people now on the mailing list and two others considering it. I think the default watercraft should be a stock kayak containing a pedal drive, small outriggers, simple commercial kayak sail, and the network node described in Nomadness Notes #23. I’m hoping this group will take on a life of its own and develop in parallel with the Microship…

Microship Status 08/06/93

Time sure passes quickly when you measure it against progress. I arrived today full of caffeine and bluster, armed with a TO-DO list of epic proportions. By mid-afternoon, I had written an article for the FLOTILLA alias, basically giving other people a TO-DO list.

TJ and I did get our hands dirty, though: we mounted the Linear Recumbent on a wooden stand to begin the mockup process. On the first pass, with the seat low to the ground and the front dropouts 8″ up to allow pedaling without heel-dragging, the required deck height for knee clearance is so great that there’s only room for about 8″ of console height if I also want to see the water ahead and not just video of same. Unacceptable, of course, so we raised the bike stern by sitting it on a box, concluded that it was an improvement, and left it at that for the evening. Tomorrow I’ll try to optimize the bike frame placement and hopefully start hot-gluing cardboard. A commercial hull of suitable dimensions may be hard to find… apparently, most trimaran outer hulls are asymmetrical…

I had a good conversation with Mark Livesay in El Cajon, who is knowledgagable in composites and honeycombs. He feels that the polyurethane foam-core panels are a poor choice, and will quickly deteriorate (indeed, they powder easily on contact, and this will happen internally when the panels are cyclically stressed). He says the foam is useful only for flotation, has no structural value, falls apart when wet, and suggests instead “Nidacore.” This is polypropylene honeycomb, which I would use without fiberglass, bonding the solar panels directly to the top facing. He further refers me to a fellow in Florida with extensive multihull experience, and cautions us to be extremely careful with the stresses at the hard points in the outrigger structure. Enough people have warned me about this that I’m listening…

Spoke with TERC (Technical Education Research Center) today about funding for Microship-based educational programs, complete with instructional materials and administration. They’re serious. Could be interesting… I’ll keep you posted!

The lab is about to be under seige — in my continuing quest to get the power straightened out and security installed, I discovered that the building is going into major renovation starting next week, including re-roofing, re-doing power, tearing up walls and floors, and other surgery. Lovely. I arrived yesterday to find that the security system on the bike had been triggered and the other one shut off. Someone has been in there… I feel like I should start sleeping there so I don’t have to worry every night. (At least the office now has a new lock, off the widely propagated building sub-master.)

Speaking of sleeping, I’m looking for a place to live starting in September — going tonight to check out a place. Hopefully there will be more project news over the weekend!

Microship Status 09/08/93

RED ALERT! Major crisis… turns out the “lab” in the old bookstore building is falling victim to the ravages of major renovation… starting today. I arrived this afternoon with guests only to find that the doors had been broken open, shelving moved out of the way and crammed against BEHEMOTH, and parts spilled on the floor. Noting is missing as far as I can tell, but there is now NO security whatsoever there and the contractor has informed me that they’re ripping out my overhead door, building a walkway, adding a door, sealing over the other doors, etc. In other words, I have to get out immediately… now that I’ve spent many days, with three other people helping, moving in, unpacking all the boxes (only yesterday!), and setting up a functional workspace. This is maddening, and a huge waste of precious time and energy. The contractor says he might be able to delay a few days, but faces a $500/day penalty clause if he doesn’t make his deadline. The work they’re doing on the roof will expose the lab to predicted rain, and the rest of it is structural renovation including extensive framing and drywall. I have to get out NOW. (Actually, I won’t miss the place — I’ve been worried about security since I arrived there, not helped at all by furtive voices right outside my door the other night.)

And so, if any of you around UCSD happen to know of some clean lab space I can move into immediately, please let me know ASAP. It’s also going to take a work party of some volunteers to get it done, once we know exactly what “it” is. In flagrant violation of university policy, I’ll provide the beer…

We need to get the administrative and facilities departments on the Net, by the way, so one hand can find out what the other is doing! My $260 order for a direct line from the lab to the police security board is partially complete as of Friday, and there is a work order pending for electrical work on my lights and outlets. I was tipped off Friday by Debbie in telecommunications that there would be some construction work going on in the old bookstore, but didn’t expect to have it amount to an unannounced frontal assault!

Despite that major distraction, work is proceeding. Excellent discussion today with Dave Berkstresser and Dave Wright, visiting this week from Silicon Valley. This is the first of many meetings with them this week (though the non-maskable interrupt of getting driven out of the lab might significantly curtail productive time as I move everything to some yet-unspecified location). We discussed the structure of the outriggers, hull fabrication methods, and related mechanical issues.

I also shipped the Icom proposal package (Marine HF and VHF), arranged an all-day Friday excursion with Tom Nute into the rarefied world of San Diego’s yacht design heavies (including America’s Cup designers and our potential sail rig sponsors), received detailed mechanical drawings on the Solarex panels, studied PC/104 standards and available products via new Ampro literature, advanced the discussion in the flotilla alias, and dealt with a silent-but-deadly Mac crash that required me to rebuild the contacts database in FileMaker Pro (which is molasses in that mode).

I was planning to work on the cockpit mockup tonight, but it was to have been affixed to the vertical columns in the lab for support… no point in investing any more energy there, I guess.

Hopefully, there will be better news tomorrow!

Microship Status 08/16/93

As you probably read in the previous daily report (um, one week ago), I had a bit of a setback in the form of demolition crews tearing uninvited into my lab. This constituted a non-maskable interrupt, and major panic ensued. With the help of Clark Guest and Ron Fellman, we managed to secure the Microwave Lab adjacent to my office as temporary lab space (until spring), whereupon TJ and I did most of the move under human power last Thursday. Today Kevin Hardy and I will haul the remaining furniture (workbenches and tables) down to Seaweed Canyon (which will, SOON, be the boat shop…).

But despite all the logistical interruptions, PowerBook repair (talk about source of stress and panic…), and a weekend of sailing a J24 offshore, there have been some major advances in the project.

First, I had a good brainstorming session with Dave Berkstresser and Dave Wright, visiting from Silicon Valley. Much of the discussion focused on outrigger attachment and stress distribution, as well as solar substrate design, folding ama arrangement, and a method for lifting the amas a few degrees to allow me to fly a hull on a beam reach. While the design is my no means stable, the problem is now much better understood, and as Dave B often observes: “now that we’ve proven that it’s possible, all we have to do is refine it.”

Friday, I hooked up with Tom Nute (formerly of North Sails) and took a tour of the yacht-design community in San Diego. Most notable was a 5-person meeting at Sobstad Sails, attended by Mark Reynolds (president), two of his designers, and Robb Walker of Nelson/Marek (they designed Stars and Stripes). Fortunately, I had the BEHEMOTH media binder with me and generated enough credibility to offset what must amount to obvious ignorance about boat design — by the end of the meeting, both companies had expressed a willingness to contribute design work and products. We also visited North Sails, Downwind Marine, West, Kettenburg, both major yacht clubs, and a few interesting individuals slaving away on their aquatic dream machines. Between all that and much brainstorming with Tom and others, here’s a revised look at the Microship’s overall structure:

The center hull is now in the 28-30 foot range, 4 feet wide, probably to be constructed with West System’s moldless strip-composite technique after lofting from the CAD artwork. Outer hulls and solar panels are pretty much as defined prevously, though given a higher freeboard, the outboard edges of the panels will be well above the kayaks and connect to them with vertical posts (containing inflatable flotation bags to allow kayak-deployment without serious center-hull imbalance). Two cockpits fill the 10-foot space between the major structural beam assemblies, with a free-standing indexed roller-furling carbon-fiber mast integrated into the forward one to carry the transparent tedlar sail (genesis design). The mast sits on a thrust bearing and is rotated via lines to a drum at the base; an internal slip-ring assembly prevents cable twist to the masthead assembly; an index pin constrains reefing to 360-degree increments so the bicolor always makes sense; the leach of the sail is laminated with UV-inhibiting fabric to protect the sail itself when furled.

To solve the problem of getting a multihull through a tack (normally managed by backwinding the jib, Hobie-style), we plan to add a front rudder off a bowsprit, designed to kick up on beach impact. This will speed tacking, but also provide a very effective appendage that allows fine-tuning of the CLR (Center of Lateral Resistance) in conjunction with the rear rudder. This should eliminate the need for leeboards.

A pair of cowlings outboard of the hull body houses retractible wheels, pivoted from the hard points associated with the aft beam assembly. These include trailing-arm suspension to absorb road shock, and convert the boat into a trailer towed via a ball-hitch receiver on the bowsprit. Obviously, a bit of preparation is required before entering this mode: the kayaks stow atop the main hull, the four solar panels wrap around them, and beams and mast assemblies are lashed inside astride the console. The wheel cowlings provide virtual deck surface for the complex set of control lines and their associated cleats.

Deck layout is evolving to take advantage of the increased space. The main cockpit is still based on the bike and console; but the bike’s forward mount can be released and dropped into the bilge to clear the way for the crew cockpit’s cushions to be converted into a 4×7-foot bed that is safely under deck. I will still use the tented on-water bivouac mode described earlier, but that presents problems with windage and security (and is much more work when I’m exhausted).

There are six bulkheads athwardships, with the electronics bay further bisected along centerline into a pair of sealed enclosures, one each for comm gear and general electronics. This is to contain flooding in a severe emergency, as well as to enforce isolation between equipment classes that have been proven to be mortal enemies (RF and computers).

Further details are best communicated graphically — I should have a new drawing of all this in a few days and will distribute it appropriately.

In other random news, I’m studying info on non-ceramic head options, wind generators, International Medcom’s new radiation monitor that includes a wide-aperture gamma probe, night vision equipment, video, and much more. I’ll keep you posted!

Microship Status 08/18/93

(OK, so I’m slipping a bit with the daily updates… TJ complained that he can’t get to sleep without them, so I’ll try to be good from now on. 😉

The Microship is getting bigger (Hey, think we can use the name QE3 without getting in trouble?). As I add features — like the ability to carry a second person in comfort and the ability to crawl into the main hull to sleep — it grows. A rough layout in plywood and scrap lumber the other night yielded a 4′ wide, 28′ long main hull, with the same solar panels and kayaks as before. This might shrink 15% or so, but is probably on the right scale for what amounts to a live-aboard, however minimal.

Adding that extra foot of width to the main hull (now possible because it doesn’t have to be an off-the-shelf kayak) works wonders for console real estate, deck surface area, and equipment packaging/storage. Suddenly I can stop worrying about cramming it so densely that buoyancy is a problem, and there will be places to route the suite of control lines:

2 – bow rudder depth/deployment

2 – bow rudder control

1 – stern rudder deployment (spring return)

2 – stern rudder control

1 – mast detent release

2 – mast furling

2 – traveler position

1 – main sheet

1 – thruster retraction (gravity deployment)

4 – ama elevation, if there’s an elegant way to do it

X – solar panel retraction

(The latter, yet completely unclear, is needed to remotely retract the solar panels without having to crawl around on a pitching deck in worsening conditions, trying to straddle 4 feet of violent ocean while tying back huge, flat, lightweight objects that prefer to flail wildly in the gale. I suspect it will take the form of convoluted and trouble-prone lines that run through blocks all the way out to the kayaks, then double back to the “knee” of the folding solar array. Retraction thus would consist of automagically releasing the hold-down mechanism, letting the center hinge pop up slightly (yeah, right — in a heavy wind), and then hauling them down tight, folded. On second thought, maybe crawling around the inter-hull void IS easier.)

As to solid progress in the last few days, there has been little. Interviews, phone time, imaginings, sketches, more product data sheets to browse, the beginning of the housing quest… hopefully the next few days will see real solidification of the plan so I can begin a weight-distribution spreadsheet and put together the first pass at specs for the hull-design folks. I can’t wait to start doing hardware!

Microship Status 08/24/93

The kayak is becoming a kayacht!

Hard at it, despite lack of reports. Much of the time these days is wall-staring and sketching, trying to nail the center-hull design goals firmly enough that we can express them as a CAD drawing, map the distribution of gravitationally significant components, and pass the whole thing to the naval architect. At the same time, I’m watching for an existing hull that is CLOSE to what we want, hoping to bypass the massive time sink of lofting and hull fabrication. A talk with Wayne Marsala last week emphasized the choice of Current Designs kayaks for the amas, and I’ll be talking to them this week.

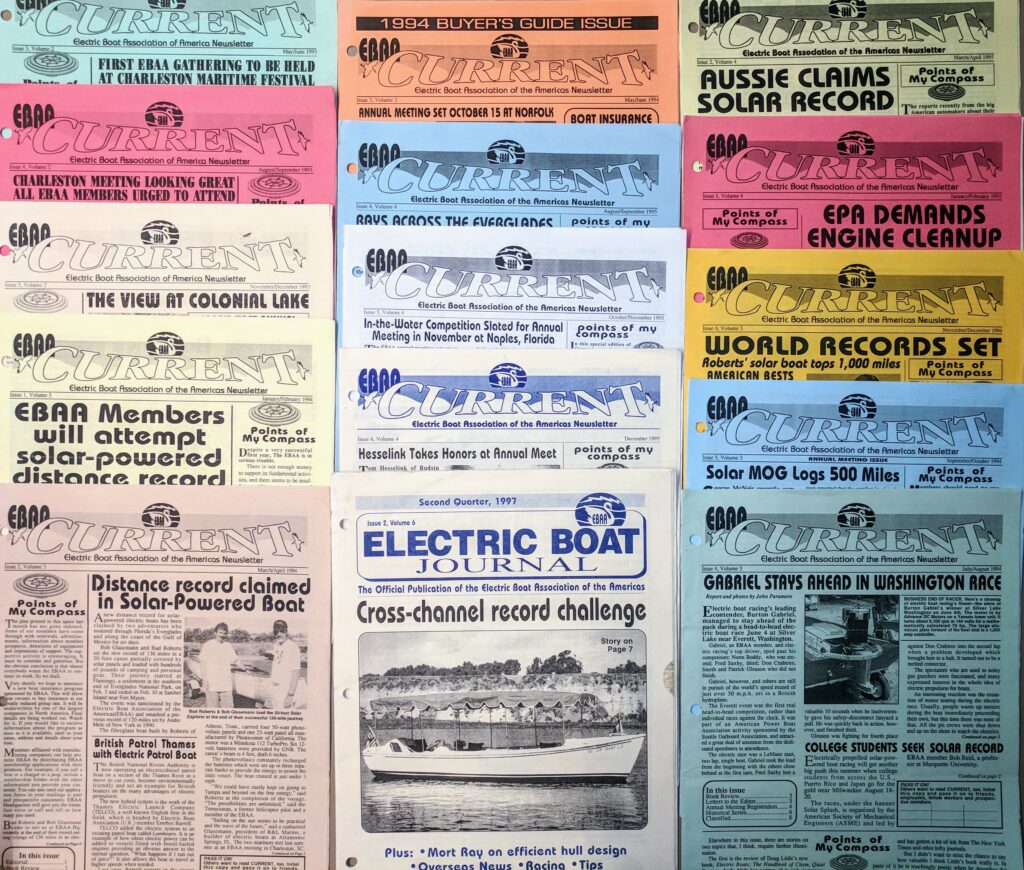

I had some interesting discussions yesterday with electric boat people, referred to me by Solarex. Ken Matthews runs the EBAA, an association devoted to building and racing electric boats. Kirk Elder is preparing for a solar-powered circumnavigation of the world, and is sending some info on thrusters, generators, and his own boat. Morton Ray makes a 3HP electric outboard motor that’s purported to be efficient, and Marshall Duffield has a commercial electric boat. All part of the homework — I don’t know how relevant this will be, but it’s part of the education process.

Tom Nute spent a few hours here the other day, and we seriously discussed adding a second mast at the other hard point (the first is on the forward aka; this on the aft). This adds power, gives better running performance, improves tacking, and adds a perfectly-located support for a tent ridgepole — minimizing the need to keep a free-standing unit from blowing away. I’ll discuss this with the gurus at Nelson/Marek, but it’s rather appealing.

We had a good meeting today re the student project classes in ME and ECE, and how they might interact with each other and with industry via this project. Lots of enthusiasm and cooperation… it will be interesting to see how this shapes up. I’ve already had positive feedback from three industry sponsors on the suggestion that they get involved with the student projects at some level beyond traditional equipment sponsorship, though just what that might mean has never been explicitly stated. Engineering help, development systems, funding support, project tie-ins that have product potential…

Beyond that, I’m still gathering data, devouring magazines like Multihulls and Ocean Navigator, talking with yachties, inhaling product literature, and trying to keep it all sorted and somehow portable enough to pass along to whoever gets their hands dirty with me. Sok Sun came by this weekend and we did some office cleanup and organization, I spent some time Sunday in a real-life demo of CE/CLR relationships (see, I can even define windsurfing as relevant research!), and landed a deal to write about the Microship in Internet World magazine.

Microship Status 08/25/93

First, a minor aside gleaned from rec.boats in a thread about marine radio:

It is also a requirement that the license be displayed near the VHF. We have had several friends boarded by the Coast Guard recently and both were cited for two violations:

1 No garbage plan written up in the ship’s log

2 The License was tucked away in a locker – not mounted near the VHF.

Another detail to remember! Somebody remind me to leave a spot in the below-deck comm console for administrivia, OK?

I spoke with Nelson/Marek yacht design again today, and they reiterated their support and helped clarify the steps I need to take first. Basically, it amounts to ignoring issues of hull shape and concentrating on two things: arrangement of hatches and other human-interface components, and creation of a spreadsheet listing items by weight and LCG (relative to station) and VCG (relative to waterline). So the major focus now is on refinement of the center-hull layout to the point where we can do some real drawings and hand them off to the wizards. (Although… I’m noticing that trying to do layout while ignoring hull shape is very difficult… I don’t know what depth assumptions to make.)

The other up-front design issue is to define the projects that can be quantized and passed on to student groups. I’ve already started this, but if any of you want to help brainstorm it let me know. Basically, the interesting projects will be those that meet the following criteria:

- Clearly defined subsystems or components

- A scale that can be completed in a school year by mortals

- Likely industry sponsor involvement

- Technology that pushes the envelope instead of reopening old ones

- System integration that helps foster team engineering

- High-profile, visible, cool stuff that’s visible to the media

- Publishing potential for shared bylines

This leaves out some of the pressing issues like general packaging and device interfacing, but still leaves a number of the more challenging issues available as student projects.

In the overhead department, I’ve probably found a new place to live, now that the summer sublet is about to disappear. Details when it’s real…

Microship Status 08/27/93

Ah, THIS is the way I like to work. Suddenly it feels more real. It’s 2:30 AM, and I’m still at the lab, cranking away on a quarter-scale CAD (Cardboard Aided Design) model of the crew cockpit. Ideas that were vaporous at best now must stand up to physical constraints, and visualization is infinitely easier.

I’m doing segment V4 first — the 8-foot module that supports my co-pilot. A folding seat can be nestled into the sleeping deck to yield a smooth 4X7 foot sleeping space with four opening ports, and various hatches below this level provide access to gear. Drainage is into a protected bilge. Some of the space below this sub-deck is devoted to sealed flotation compartments. Once this series of four models is complete, they will velcro together on a display stand and help us make sense of this design… and allow better communication with the naval architect who is going to do the hull design itself.

Progress!

I’m adding a new section to these reports… “Literature Received” So much interesting material comes through here as a result of my inquiries that I should let you know it’s available. I’ll start today with some of the interesting recent stuff, then keep it current as new material arrives in the library. It will appear at the end of the report.

Continuing with the general requirements design, I’ve been thinking about getting out of the weather — in addition to the “cabin,” which is the sleeping space in the crew cockpit V4, both operating positions will have biminis. A possible high-WQ implementation of this is to use actual convertible soft tops, which are about the right size. Now if we can just add power windows… 😉

I did a posting to rec.boats yesterday, introducing the project and asking advice on matters various. I received a tremendous response, with about 20 letters from experienced mariners commenting on strip composite versus fiberglass layups, head selection, celestial training, front rudders, instrumentation networks, and more. It’s an excellent newsgroup.

Back to hull design (someday we’ll be past this and doing electronics, but first things first), here’s the text of a letter to TJ earlier today. He is working on AutoCAD drawings for proposals, visualization, and publishing early progress reports:

I just spoke with Robb Walker, who told me not to worry about the shape at all, but just design requirements. Well, we need to worry about it SOME to know how much volume is down there, but let’s must make it simple. Upswept vee bow, gradually faired as it goes back, squarish upper deck at stern with smooth closure at waterline (but full-length, for maximum hull speed). Sort of like a big kayak with a more functional deck. I’m now toying with revision 937 of the sketch — four major compartments:

V1 – 7′ – bow, flotation, antennas, and gear hatch

V2 – 3′ – head, water processing, wet data collection

V3 – 10′ – SKR cockpit, electronics bays, gear stowage.

V4 – 8′ – crew cockpit, cooking, sleep space, gear stowage.

The puzzles involve conversion between crew-seated mode and sleep space, as well as the most painless way to get access to electronics bays in a 3.5-4′ deep hull. I’m thinking that gear hatch could be on top, in the center, and we’d remove packs to get at the pressurized space below.

This provides easy place to stow packs and stuff, with ample space below for electronics. But there’s a long way to go to figure out access details, shock mounting, cabling, waterproofing, pump location, hull supports, etc.

LITERATURE RECEIVED

(catch-up mode since this is the first appearance of this feature — normally this will be about 1-4 listings a day). This is included in these reports as a library function — project participants can grep this stuff from the Microship Status Report archives to see if information is available in-house before incurring research delays. Also, if it’s not here… ask! I’m not going to list the complete contents of my file cabinets and bookshelves, just the latest noteworthy additions.

Multihullshop Catalog: excellent resource of books and other materials on cruising, seamanship, multihulls, design, construction, and technical matters.

Robert E. White Instruments: Catalog of sextants, barographs, leadlines, dividers, binoculars, plotters, compasses, epirbs, and accessories.

Too Tek flyer: night vision equipment from $450 to $1250, covering light amplification levels from 1,500 to 60,000.

D. F. Crane Associates: Thorough catalog of marine computer products, including navigation and training sofwaare, simulators, tide software, weatherfax, and so on.

Wireless Industry Prospectus, June 1993. Articles on Motorola, Specialized Mobile Radio, and interviews with Steve Roberts and Richard Cortese.

Pen Magazine, #13. Many articles on Personal Digital Assistants

ComGrafix: Macintosh charting software (likely sponsor)

Tektronix literature on 1-inch color display for HUD and virtual reality applications.

Thetford 775 marine head spec sheet.

Two recent issues of Multihulls Magazine (Jan/Feb and Mar/Apr 93), and the latest Ocean Navigator (Sep/Oct 93).

Astro-Flight: high-performance cobalt PM motors for model aircraft (up to 1820 watts, if that sounds “small”).

Rip ‘n Grip: Velcro samples and literature — sponsor.

Silicon Valley Bus Co: literature on Multi-port expander to add serial ports to the Macintosh.

Protel: PCB layout software for Windows, with demo disk.

Maptech: Charting software

Gougeon Brothers on Boat Construction (book): West System epoxies, strip planking, lofting, and other boat construction issues.

Enough! Time for one more CD and completion of the foam-covered seat model so I can pedal back to the apartment by 3 AM…

You must be logged in to post a comment.