Microship Updates – October 1993

Microship Status 10/01/93

There is a waterproof full-travel keyboard in the world! The company is Paravant, which makes laptops for military and rugged field use, and they’re talking about it now to see if they want to release a keyboard only for this project. I promised them publicity and any data on interfacing and application…

The help flyers are starting to get nibbles — had a brief meeting this morning with Mike Brokowski, in ME. He’s had 5 years in the Navy working on nuclear reactors, so has had his hands on real equipment… we’ll meet again tomorrow to talk about specifics, and another call came in this afternoon.

Good talk with Kurt Hughes, a multihull designer in Seattle who is becoming known for the cylinder-molding technique. He feels that my boat will be slowed by the use of kayaks as amas, since a true ama is much faster. Trade-offs can be brutal… anyway, he’s sending his new book of designs and info, so we’ll get to study some more possible solutions to the problem.

Short one today — afternoon at the beach, evening music and party, followed by a bit of writing…

Microship Status 10/08/93

I did a talk for the student section of ASME a couple of evenings ago, and it went well — lots of interest from students in working on the system. Between that, today’s all-day demo on the Sun God lawn, and the response from a flyer I’ve been distributing around campus, I now have a string of meetings set up with potential participants. Coming soon: the unfamiliar problem of having to manage a largely inexperienced but very enthusiastic workgroup…

Good progress on the user-interface front: InterLink, maker of force-sensing resistors, has an industrial-grade, submersible pointing device on the market! I haven’t felt it yet, but they’re sending one — this may eliminate the need to design our own with the XYZ array that Ron Fellman took to experiment with a couple of weeks ago. I told the InterLink guy about that and he felt that their solution is easier (though I’m not sold on the concept of mapping force to velocity on what is essentially a zero-displacement joystick — actual movement, with a Z-force-derived velocity multiplier, sounds more intuitive).

For the past couple of days, I’ve been trying to get a handle on all the developing sponsor and help relationships. I hate to have to say this, but paper is still more effective than computers for some things. In order to handle the full range of project-management issues including scheduling, people, sketches, musings, TO-DO list, and much more, a big fat binder turns out to be easier and more intuitive than all the database tools at my disposal. The latter involve the imposition of structure, and hide information in rather unbrowsable places in machines that have short battery lives and aren’t always with me. The former is simple, non-volatile, endlessly expandable, and visual… what PDAs should become after they survive their infancy.

Short on technical updates at the moment… I’ve been overloaded with the human help quest and a couple of writing projects. We’re getting close to beginning hands-on work at last! Enjoy the weekend…….

LITERATURE RECEIVED

Practical Sailor, Oct 15 issue — the Consumer Reports of sailing. This one covers boom vangs, belt-pack PFDs, and hand-held VHF radios.

Midnight Engineering magazine, Sept-Oct issue. A worthwhile resource focused on engineering embedded control systems — this one has a good article on the Microchip PIC processor which is a strong contender for Microship distributed control.

Dimensional drawings on Qualcomm’s new satellite terminal.

West System epoxy resin catalog and tech manual.

NOTE: At this point in the series, I posted the Microship Project Overview and Microship Project Catalog which are already elsewhere in the archives.

Microship Status 10/19/93

This issue is going to about 20 new project volunteers as well as the 20 usual recipients (major sponsors, project participants, UCSD faculty, and close friends). As you new folks move from having innocently expressed interest to becoming drawn into direct participation, you’ll be moved to the list that routinely receives these updates…. that is, whenever I actually WRITE them. I’ll also put you on the huge Nomadness alias (over 3,000 people) for the occasional full-scale chapters, but those are much less frequent than these, um, “daily” reports.

The past week (!) has been crammed with managerial work and a few noteworthy developments. In the former category, quite a bit of time was involved in the creation of the “Microship Projects Catalog” which you should have already received. Although that was exhausting, it was an extremely useful formalization of the whole system and has already proven its value as a framework for project planning. It’s also giving project volunteers something more tangible to think about than the vague notion of “helping that guy build a boat.”

Today I had a very enthusiastic meeting with four people from Nelson/Marek (the marine architects who are designing the physical boat for us). This ranks as major support — without them, my options would consist of bumbling through the process of inadequately reinventing the wheel, or trying to retrofit a set of unique requirements onto a commercial boat designed for different purposes. Nelson/Marek’s contribution of design expertise is significantly increasing the probability that this will be a successful system.

In the meeting, after the requisite BEHEMOTH demo, I talked through all the requirements of the Microship — then they gave me some homework to do. Step one: define the weights and general locations of all known gear. This will help determine waterline, fore-aft buoyancy balance, locations of bulkheads and outriggers, and so on. Actually, this has been discussed before, but now I have a spreadsheet and the benefit of some solid discussion on the level of detail required (and its rationale).

Robb had an interesting idea today… I don’t know if I’ve spoken in these reports of the crossbeam angle (dihedral) issue, but it’s a sticky one. In short, where relative to center-hull waterline should the outriggers be positioned? When under sail, it’s good to have them high so I can reduce wetted surface by flying a hull. On flat water under solar propulsion — or at anchor — this would drive me crazy, tipping back and forth with every move. We’ve had some discussions about clever ways to tweak this, most involving too much mechanical complexity.

“Why not just sink the center hull?” Robb asked — responding to my panicked look with the explanation that flooding or pumping out a ballast chamber would let us have the best of both worlds. At rest, the tank is full, lowering the boat until the outriggers are carrying their share of the load. Under sail, we lighten it and fly. Clever. Since we can define the hull shape any way we want, including the addition of above-waterline flare, we can define the waterline-flotation transfer function up front and not have to kluge it into something that wasn’t intended to behave this way.

For purposes of calculation, we’ve established reference planes at the forward bulkhead and deck. Stations will be defined in terms of feet forward (-) or aft (+) of the bulkhead separating the forward two hull segments, and vertical CG of components will be expressed relative to the average plane defined by the hull-deck joint in the center segment (this can always be mapped to the more conventional DWL later).

There is some chance that we’ll be building our own outriggers as well, and not depending on commercial kayaks. While this seems like an instance of the Not-Invented-Here syndrome, it is appearing that solving the problem right will require either some aggressive kayak hacking or hulls designed from the keel up to suit the Microship. Among other issues, they have to be bulkheaded at 10-foot intervals to suit the placement of crossbeams, they will require extremely beefy decks to accommodate the stresses of attachment, and all hatches and cockpits will have to be fitted with covers that won’t wash off in rushing water when I’m burying a hull at 20 knots. These are things that kayakers don’t have to think about… yet the amas must still be operable as kayak-like craft (albeit pedal powered) when detached from the mothership. Should be interesting. At least, this way, we can make all the hulls visually match…

(At this point, I attempted some ASCII graphics to show the proposed network architecture)

Basically, we’re dealing with different computer worlds here. When I’m on board and working, I live in the Mac world and want AppleTalk. It will be extended via Digital Ocean’s wireless boxes to the manpack laptop and the machines on neighboring boats, but basically it should feel like a cozy office network of Macs (complete with hooks to cellular and satellite-delivered email).

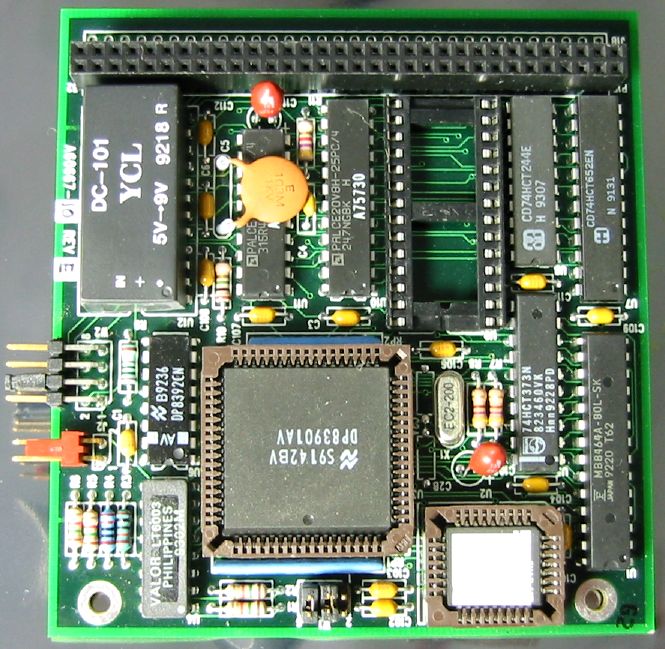

A network gateway ties my “personal productivity” machines to the boat’s DOS world, consisting of two machines — the Compaq 486 for navigation, charting, and marine software… and the Ampro PC/104 system that is the diskless, low-power hub for the Microship control system. Both of these get to see the NMEA-standard bus for communication with shipboard nav and off-the-shelf maritime instrumentation. The concept here is that marine functions will pretty much take over a machine, and I don’t want to have to keep context switching my Mac between productivity and survival. This also gives me two major platforms /for available software, minimizes single-point failure potential, and doubles visual display bandwidth. The keyboard and pointing device will be seamlessly switchable between the two worlds.

The Ampro machine (MCS) is in charge of a multidrop network of extremely low power, cheap, distributed servers and controllers — each dedicated to a small and manageable task. If you recall the project breakdown in the mega-document I just sent you, then you’ll recognize these… each is owned by a project group and localizes failure potential to a single functional region.

Because of low power and the need to have peer-to-peer access between controllers, this is also the interface point for external packet-radio or laptop access to the kayacht’s control system. High level logging in (via telnet or email daemons, PPP, or whatever) will take place in the Mac world — responding to a power-control command from one of the tiny machines that’s always on and listening.

Sailing just ain’t what it used to be……..

Enough for now. I’m having a succession of meetings this week with new project volunteers, then planning a group meeting sometime soon to start nailing down specifics. The hottest human-resource issue right now is management: I need a team of 3 people who are collectively cognizant of ALL parts of the project and want to help manage the focused workgroups. This will be time-consuming, but very exciting since you’ll get to play with everything at once. If this is for you, please talk to me NOW!

Cheers from a thrilling Friday night on campus….

Microship Status 10/21/93

This issue of the MS status report is primarily directed to new volunteers — the 25 or so UCSD students who have, within the past couple of weeks, expressed a strong interest in getting involved in hands-on Microship development. I am also sending this to the normal status-report mailing list (faculty, industry, friends, and established assistants) for context and update purposes…

Here’s what’s happening with team development: I’ve now met over half of you, enough to know that there is a good mix of talent and intelligence out there. Some are beginners but eager to learn; others have spent time in industry or the military and already have a good feel for how things work. Some are working in technical jobs now; some are up to their necks in coursework and want to start on this next quarter; others are looking for something to do.

It’s becoming clear that I have an interesting management task ahead, and putting together the “triumvirate” is going to be a critical part. Just as a reminder, I’m looking for three sharp people, well along the engineering learning curve, preferably with some industry experience. In the ideal world, this team would include one each from ECE, ME, and CS… but more important than that distinction is a good mix of verbal, design, and management skills. Hopefully we can secure independent study credit support from faculty for management, since a good percentage of graduating engineers are heading directly for management roles in industry. If you think you can manage other people, AND you have a wide range of interests covering a fair percentage of the Microship Project Catalog, please contact me ASAP.

Second, in addition to the project-specific teams, I want to create a “labor pool” of less-experienced people who wish to be involved but aren’t ready to take on system responsibility. I rather like the thought of different design groups drawing on a resource of beginners, calling them in to help with wiring, testing, asset relocation, board fabrication, abrasives engineering, coatings application, and other tasks that are relatively well-defined but close enough to the project to be interesting. Those in the pool would become familiar with a number of subsystems, moving into more aggressive roles as their education progresses.

Finally, I want to use these reports to begin calling for immediate help with specific things. A number of you have offered to assist in any way, even if not with the “glory” projects like control system design. I will periodically include a list of current needs in these reports, welcoming any volunteers who want to help out. Here’s the first such list:

–> Seaweed Canyon shop organization. This Saturday 10/23 at 10:00, I want to take a small workgroup to the shop at Seaweed Canyon (part of Scripps Institution of Oceanography, next to the aquarium). The purpose is to set up shop: it’s currently a repository of my unused goods and furniture, scattered loosely about. Since this is where the hull will be fabricated, we need to get things organized and set up in anticipation of building the boat. While the labor requirement is rather minimal, having 2-3 people with me will help get it done in 2-3 hours! We’ll arrange furniture, deal with boxes of stuff, and plan workbenches and supply storage facilities. A lot of us will spend a lot of time here once the fun starts — now’s the chance to make it comfortable and efficient.

–> Status report archives. Does someone want to take on the monthly job of printing archives of these reports? It never seems to get done here with my slow little printer and overloaded TO-DO list. I have them all on my Mac, and can email them to you or hand you a disk. The idea is to have ftp-able files by month, as well as a binder going back to the beginning (I’ve printed July…) to help bring newcomers up to speed.

–> FTP site maintenance. (Alec?) Again, files are on the Mac — I’d like to find someone to take care of that publicly-accessible archive in ucsd.edu. At the moment, we need to update the READ.ME files, install some new material, and make some of the file names a bit more logical. People access this from all over the world, and it should be easy to use and current.

–> Extract 40 or 50 position fixes from my Motorola Traxar handheld GPS and put them in a file. I need to ship that unit back to the company.

–> Acquire a scale and help me put together the table of weights (Excel spreadsheets) as an input to the hull-design process.

–> Install DuraPoint mouse driver in a DOS machine on campus and test the unit for sensitivity and comfort (letting me play with it, of course). This will move immediately to a Macintosh-interface project when and if we decide it’s the right pointing device for the console. (The bookstore said we can use one of their machines if necessary…)

–> Re-organize my CD library, moving liner notes into the vinyl viewpaks that will be used to carry both music and CDROM disks on the boat. Find a case that will work well and fit into the equipment rack.

–> Pack up some equipment (an H-P laptop, a Tadpole SPARC laptop, the GPS mentioned above, and some cassettes) and ship as specified.

–> Spend about 3-4 hours with me organizing and filing (mostly manufacturer’s literature, magazines, and floppy disks).

–> Lab clean-up. If you’ve seen my lab in EBU-1, you know it needs it. It’s time to make this place into a working lab — for this, I want someone who has worked as a technician to spend a few hours with me, evening or weekend. I hate living out of boxes!

–> Install the lab security system with auto-dialer.

–> Get the Linear Recumbent rear wheel trued, assemble the bike, and take it for a test ride (jeez, did somebody call this WORK?).

There. Our first list of CDTs (Clearly Defined Tasks). I look forward to working with you!

Microship Status 10/23/93

Circulation of this issue: 50

First of all, a big THANK YOU to Mark Jones and James Gerken for the help Saturday morning! We went to the Microship bay at Seaweed Canyon (next to the Aquarium) and spent about three hours converting it from a cluttered mess to a clean, ready-to-use shop. (I even overcame my tendency to keep everything and, in a rare catharsis, tossed out a couple hundred old copies of EDN, Byte, Electronic Design, PC Week, MacWorld, and various other trade journals.) We set the space up so it will accommodate a 30-foot hull fabrication project, with shelving and workbenches on one side, tables on the other. My Sealution sea kayak is now in there as well, giving the place a distinctly nautical flavor…

The quest for volunteers has been remarkably successful, and my “paper database” of people now numbers 34. There’s a wide variation, of course — some will probably never progress beyond first contact while others will become deeply involved; one person (Jesse Keller) has already informed me that he’s become immersed in the human-powered submarine and won’t be available to this project until next year. (We’ll keep you on the mailing list, Jesse… good luck with the sub!)

Frank Araullo will be handling the monthly print-archiving of these reports, his roommate Dave has offered to tune up the Linear Recumbent, TJ Tyler has offered to be the mechanical third of the management triad, Len Wanger of SDSC will be doing the 3-D renderings of Microship artwork, Isaac Chu offers help with lots of organizational and lab issues, Alec Plumb will be helping with unix file maintenance (though Fetch on the Mac has greatly simplified that problem!), and Andrea Woo is interested in helping with office tasks as long as she gets her hands on some real mechanical engineering. Discussions are progressing with others on specific projects… thanks to all who have come forward to help get this project underway!

In other news…

I received a book from Kurt Hughes Sailing Designs (Seattle), detailing dozens of catamaran and trimaran plans that he sells for a few thousand dollars each (the plans, not the boats!). What is of interest here is that he seems to be pushing the envelope on many multihull design and construction issues, avoiding getting tied down to old molds that have to be amortized over a decade or so. I delivered this to Robb Walker at Nelson/Marek Yacht Designs (who is newly on the Internet as of Friday — and on this list), and he’s integrating the ideas into his thoughts about our design. He has also offered to contribute some hands-on management of the physical fabrication — a MAJOR asset since he’s been through this process on everything from sleek little racers to multi-million dollar mega-yachts.

While in the Shelter Island area Friday (with Dave Wright, a friend who’s off to the South Pacific as crew this season), we also stopped into Pacific Marine Supply. This is a long-distance cruising-oriented store, and one of the proprietors (“Radio Mike,” WB6ERA) is an active ham, runs local marine HF and VHF nets, and otherwise knows the maritime communications issues. PMS also hosts parties at which cruisers and crew mingle and form alliances, so we’ll have to wander by there occasionally. (If any of you want to get educated on the yachting and maritime culture as background for this project, I highly recommend a day walking around that part of town — contact me for some specific recommendations or to get on the list for a “field trip.”)

I’ve added everyone on this list to the nomadness alias, which, like technomads, has just been installed on the UCSD listserv (thanks to Brian Kantor). Back issues, not quite up to date but soon to be, are available via ftp from ucsd.edu — look in the /nomad directory. The READ.ME files still say Telebit, which was the previous host, and the last 3 or so issues are missing, but Alec and I should have that taken care of in a few days. Anyway, the nomadness alias is a big one (well over 2,000 direct addressees including known reflectors and exploders, plus thousands more via forwards and reposts across the Net), and it carries more polished and abstracted updates on the project of interest to the world at large (less local detail, more stories and “articles”). These are a direct descendant of the “Notes from the Bikelab.” You can also get them in hardcopy subscription form by sending a check to my office… but you’re on the Net. Why would you want to do that? 😉

Quick update on the solar arrays… I spoke with my apps engineering contact at Solarex and told him about NidaCore — initially to find out the acceptable deflection of the cells so we can spec substrate thickness assumming worst-case loads (not much — about a centimeter over .6 meter). Anyway, my description of the polypropylene honeycomb quite intrigued him, so we’re having some samples sent — this may be another case of unexpected synergy between two sponsors who had not previously heard of each other. I’ll keep you posted.

Finally, I haven’t done a LITERATURE RECEIVED update in a while… here’s what’s new in the Nomadic Research Labs library:

Cruising World, Nov 93 issue, with an excellent article on seagoing women (relationship issues) as well as comments on reverse-osmosis watermakers, what to do when grounded, cruising Tahiti and Chesapeake, working with acrylics, and online yacht clubs (including rec.boats).

Avon Marine catalog, including inflatables, pumps, instruments, lights, and general gear.

Global-C literature (an Inmarsat terminal)

Cruising Guide from Pacific Marine Supply, an excellent, to-the-point compendium of things you need to know when heading Out There (emphasizing checklists, radio, and dealing with the Mexican government).

CCatalog, detailing all sorts of grim accessories for weapons to make them even nastier and more efficient.

Latitude 38 (October)

San Diego Log (Oct 15-28)

Wired, Nov 93 issue. This is an excellent magazine with lots of Internet resources… for example, finger na******@*******it.edu for daily updates on mission status and recent discoveries.

Microship Status – 10/31/93

All of the work that’s happening these days has the character of a giant inhalation. Meeting volunteers, planning, choosing major components… it’s often frustrating, feeling more like management than doing a real project. But we’re establishing the directions and resources that will carry us through the next year or two, so it’s time well spent! Soon we get our hands dirty, honest….

ACKNOWLEDGEMENTS

Thanks to…

- Andrea Woo… for office help on 10/24 — in a couple of hours, we transferred most of the desk surface clutter to the filing system, in the progress having a number of conversations about Microship components and business. Another two or three sessions should get rid of the boxes of manufacturer’s literature, and then hopefully we can keep it current on a daily basis.

- Frank Araullo… for starting the archiving project of these reports. July and August are now in hardcopy, and I handed him all the rest in the form of an ftp’d Eudora folder. What this translates into is a resource that you folks should consider available: both online and hardcopy archives of detailed project information. This should be browsed by all newcomers, studied where appropriate, and grepped as needed for specific data on available library resources or subsystem background. We’ll probably put this in the ftp server, though I’m still wondering just how public I want this level of detail to be… at the moment I’m trying to restrict the close-up view to this invitation-only mailing list and not reveal all my sources and noodlings to the world at large.

- Dave Yao… for starting the Linear Recumbent project 10/25. He trued the rear wheel and is in the process of assembling the bike for a test ride: we’ll decide whether it should be integrated as a unit into one of the outriggers, or returned/sold and replaced by a simple integrated pedal-generator system. The wheel is a cheapie — alloy spoke nipples, some already in poor shape. If we DO use the bike, the weels will have to be replaced with all-stainless components. I’m worried about corrosion, and this may be what kills the Linear idea… but we’ll experiment first!

KAYAK UPDATE

Speaking of the kayaks, I spoke today with Current Designs in Sidney, British Columbia, requesting just the hulls of two Libra doubles, in kevlar hybrid layup with core mat stiffener. He may charge us for materials, but is willing to help — the reason for the hull-only approach is that the amas are going to be extensively customized with special deck fixtures, oddly-placed bulkheads, wiring, thruster mounts, high-strength couplings to crossarms, submersible cockpits, raised cowlings for pedaling clearance, and deeper-than-normal flotation compartments. Trying to do all this remotely is impossible… but developing kayak hulls from scratch is absurd when it has already been done well. This approach satisfies both issues. If this flies, he’ll ship them with a flange bonded along the normal hull-deck seam, stiffening the otherwise fragile 22′ shells and giving us something to bond our custom deck to.

!!! MEETING ANNOUNCEMENT !!!

OK, I’m going to make a big decision here! I’ve decided NOT to attend this years Hacker’s Conference in Lake Tahoe , just so I can be here with you (I’m laying on the guilt… be there! ;-). We will have our first meeting/party of all Microship project participants on November 6, from noon until 2 PM or whenever, on the patio right outside my lab/office.

This will be informal — I’ll probably talk a bit and try to develop a few initial teams, but mostly it’s a chance for us to get to know each other and brainstorm. There’s a very wide range of backgrounds and personalities here, and we need to hang out for a while and see how it feels… while also establishing intial connections and talking through some of the design issues. Also, this is a chance for anyone who has not seen the bike, boat mockups, and other stuff to do so.

I need a few people to organize this: the following tasks need to be accomplished:

— help me clean up and organize the lab

— buy a box of those stupid “Hello, My Name Is” stickers

— pick up a couple of folding tables from Seaweed Canyon (and one from the home of a friend I loaned one to)

— figure out how many people will be here (by sending an RSVP note & some calls)

— acquire appropriate snacks, real food, coffee, drinks, etc.

— take care of collecting a few bucks apiece to cover food expense

— work with me to record attendance, alliances, and ideas

— take video footage of this Historic Event for Microship documentary

— make sure there are no rules or policies that affect such an event

— help clean up afterwards

Please let me know ASAP if you are interested in running this, helping with it, or running errands.

CDT LIST

Finally, in what is rapidly becoming a standard feature of these reports, here’s the list of Clearly-Defined Tasks in need of volunteers:

–> Buy a scale to help with the table of weights that Nelson/Marek needs to proceed with hull design. Cheap, reasonably accurate, and good for up to 30 pounds or so — I have a postage scale for little stuff up to 2 pounds.

–> Go into the FTP server and update the READ-ME files, install the 3 or 4 recent Nomadness Notes to bring it up to date, and help establish a structure for new Microship material.

–> Extract old waypoint data from Motorola GPS nav receiver into a text file (about 1 hour).

–> CD organization (OK, so this isn’t PURELY a Microship project, but hey, you can listen to whatever you want while doing it… and we need to have the lab music library in a useful and accessible form since that’s what will keep us sane as we get to work here…)

–> Order or pickup coaxial cable kits from West Marine, to replace the two 50-foot lengths swiped by the construction crew at the old bookstore during the notorious Microship Lab Attack of August 9. University Facilities has agreed to pay for their replacement: 1) 386284 kit (RG8) $37.50 1) 386268 kit (RG58) $28.50

–> Order or pickup strobe light to replace one that suffered the same fate. To be useful, this will take a little more research: legalities, packaging, power, weight. If you want to learn a little about marine safety lighting, let me know and I’ll turn this one over to you.

LITERATURE RECEIVED

Ocean Navigator, Nov/Dec 93, with articles on weather, fog, trigonometry of navigation, meteors, charting errors, new refrigeration methods, and countless interesting tidbits.

CADENCE (AutoCAD magazine), Nov 93.

INFORMATION QUEST

This is a new category of help request, akin to the CDTs of recent issues but more research-related. I will periodically ask for specific information about various subjects that affect subsequent design decisions. In many cases, such questions will be directed to the relevant project group, but since we don’t actually HAVE any of those yet, this is a way to get some research started…

As with the CDTs, if you want to take on one of these just send me a note and I’ll confirm the assignment. At this point, since we’re not into serious projects yet, the only motives are education and getting involved (and getting credited in these reports, of course!). Also, since these are more research-related, they are not limited to students here at UCSD…

–> Can someone, preferably with automotive interest or background, start finding out what standards and laws exist that govern trailering? Specifically, we need to know the following:

o Is 8’6″ width now OK in all 50 states? All roads? Canada?

o What wheel dia/width is spec’d as a function of weight?

o What about hitch size and other specs?

In addition, I’d like to know what kind of issues we face by attempting to make it a 4-wheeler when the “landing gear” are deployed, specifically with regard to turning. We could do 2 wheels, but that doubles the stress on the aft bulkhead and greatly increases tongue weight.

–> I need someone to research the names “Tufram” and “Everslide,” both of uncertain spelling (HINT: that’s what Soundex codes are for in the TUS Trademark database). Dave Berkstresser mentioned these some time ago as special kinds of anodizing processes for aluminum that contain teflon and resist marine corrosion. Is this true? Who does it? What other surface treatments can be applied to various metals to marinize them? Questions like this can sometimes be most cheaply answered with a few phone calls to vendors (incidentally, please report any phone or other out-of-pocket expenses — we’ll reimburse you).

–> Are you interested in the pneumatic system? If so, one of the first questions involves the P-V calculations, including the stresses encountered in raising internal cabinet pressures to a few PSI above ambient. This is a good job for someone who has just been through the theory course on all this: how will ambient temperature change affect pressure, what kind of CFM and duty cycle specs will we need on the pump, how big a reservoir is needed, is having a Schrader valve for bicycle pump backup even remotely realistic given the volume involved, can all enclosures be effectively decoupled via check valves without confusing the data collection, and what pressure range do we need to spec on the transducers that monitor it all? I have a McMaster catalog here once this gets to hardware issues, but first we need some theory!

SATELLITE WEATHER IMAGES

I need more data on this, but an article in the latest Ocean Navigator suggests that direct reception of TIROS weather satellite images (in addition to the planned HF weatherfax) may be realistic for the Microship. They transmit around 137 MHz, and a turnstile antenna for high-angle gain, coupled with a suitable demodulator and PC software, could give us real-time images of the area we’re in. I can already acquire weather maps and abstracted, enhanced data via the Accu-Weather Forecaster software on the Mac, though at sea it will involve the cost of a connect path to a dial-up service. More on this as it develops… today I read up on the various weather fax and satellite receiver products and found a number of choices.

UPDATES VARIOUS

Thanks to Dave Berkstresser for the response to yesterday’s question about aluminum teflon anodizing… I’ll call for literature. Dave wrote:

Tufram is the name that General Magniplate gives their aluminum coating

consisting of a hard anodize with teflon pore fill.General Magniplate California

2707 Palma Drive

Ventura Ca 93003Further, any generic plating shop should be able to give you the

same thing under the name “Everslide.”

In kayak/ama/float news, I received word today that Current Designs is willing to create two custom kevlar hulls at a materials cost of $300 each. Drew at Nelson/Marek confirmed that this is a very good deal but did raise the caution that, “Since we haven’t even begun to calculate the stability needed for the Microship, we don’t know the volume needed in each kayak…” Prior to committing to the hull order (delivery estimated at 3-4 weeks), therefore, I’ve put them in touch with each other to discuss this issue.

I do believe we can achieve higher than normal “absolute flotation,” since we can define deck height and will, in any case, have a substantially raised coaming and deck to accommodate the pedaling envelope. My initial rough calculation of 1570 pound bouyancy may therefore be on the low side. The problem here is the transfer function between immersion and bouyancy: if the hull has to be sunk well below the surface to achieve sufficient resistance to heeling moment, then the cross sectional shape is all wrong. What I’m calling “absolute flotation” is nowhere near as important as achieving adequate bouyancy when fine hull lines are all that’s in the water — not when we’re churning along, dragging akas and deck fittings through rushing froth. (Disclaimer: This whole paragraph is coming from a hydrodynamics neophyte, and there are doubtless formal names for these phenomena that better express what I’m trying to say!)

Incidentally, the specifications of a stock Current Designs Libra double sea kayak including a standard deck configuration are:

Length: 21’8″ (6.6 m)

Beam: 30″ (76 cm)

Weight: 84 lbs (38 kg) (or 74 lbs for the kevlar layup)

Depth: 15.5″ (39 cm)

Volume: 184.4 g (691 l)

Cockpit: 16×31″ (41×79 cm)

Hull design: Fish form, shallow vee soft chine

WATERPROOF POINTING DEVICE

Tonight, I went over to the apartment of Frank Araullo and Dave Yao after they spent a couple of hours working here at the lab on the Linear (more on that in a moment).

Before my arrival, they installed the DOS driver software for the Interlink DuraPoint, the ruggedized pointing device based on force-sensing resistors. After playing with it for awhile, I’ve concluded that it’s worth pursuing further: next step is to create a Macintosh ADB interface for it. Such a thing MAY be available off the shelf — Frank pointed out that at least one commercial joystick comes with a patch to make it work on a Mac, though unfortunately that one ties up a serial port instead of using ADB. In any case, we should pursue this, since a mouse/trackball replacement that can be operated while immersed in seawater is not an easy thing to find.

The feel is not as nice as traditional devices, of course, though it’s more sensitive than I expected. The two buttons could stand to be lighter, and we brainstormed about ways to get a better grip on the .9-inch diameter pad (concluding that gluing a golfball to it might be a good experiment). But I think we have found an acceptable solution that will not require any special packaging effort, which is a big step forward! In use, we will want BOTH Mac and DOS functionality, with a nearby switch selecting which machine I’m controlling at the moment.

This is not yet a cancellation of the pointer project based on the same company’s XYZ force-sensing resistor array, though starting with an established product is a definite time-saver. Now that I’ve had a chance to try it, I’ll follow up by talking with the vendor about both options.

Again, thanks to Frank and Dave for the help on this.

OTHER ACKNOWLEDGEMENTS AND UPDATES

- Anthony Wei is here at the moment doing the Weipoint extraction from my first Motorola TRAXAR handheld GPS receiver, giving us an entertaining starter database of real locations for navigation practice. This is the nature of an information junkie: I collected that data, by golly; no way am I going to delete it just because I have to return that unit in exchange for the new model. In case you’re wondering, my lab in the engineering building is at Latitude 032deg 52′ 48.67″ North, Longitude 117deg 14′ 06.42″ West. The other 72 waypoints from a drive around the US are in a Mac text file if you really want to know where my friends live.

- Dave Yao and Frank Araullo completed the Linear Recumbent setup and test this afternoon. We took it out for a ride — it felt fine, with good steering geometry and surprising comfort. I’ve never been a fan of long floppy chains on long-wheelbase recumbents (preferring the stiffer but more complex crossover drive), but it seems to stay under control. The decision now is whether to incorporate this in at least one of the amas. Because of weight, size, complexity, and likely corrosion issues, I’m tending toward saying no on this and instead using a small glassed-in pedal/generator assembly. For land excursions, the Dahon Mariner (a 32-pound folding bicycle) will be adequate and much less of a spectacle. We’ll keep this recumbent around long enough to be sure, however, so let me know if you want to try it sometime!

- Andrea Woo has volunteered to pick up the HELLO tags for the party/meeting Nov 6, as well as the scale to help with weight summaries.

- Trang Luong has volunteered to pick up the folding tables for the same event (he has a 4×4, which in my experience is a quick ticket to popularity! 😉 He has also offered to help with lab clean-up next week after mid-terms, as have Jeremy Heath and Isaac Chu.

Finally, I did some FTP site maintenance today (ucsd.edu/nomad), dumping some obsolete files and installing the new Microship overview file (microship.gen). There’s still work to do: updating READMEs, making ASCII copies of the last four nomadness notes and installing them, and cleaning up the general organization a bit more. But Fetch on the Mac makes it quite painless…

Circulation of this issue: 59

This is the last October ’93 issue of these reports: 4 months we’ve been at this now! And it finally feels like things are getting physically underway… a project of this scope involves an amazing amount of head-scratching and wall-staring before the real fun starts.

I know some of you have already seen the following paragraph, but mostly for the benefit of new student volunteers on this list I want to quote myself (yeah, tacky, I know…). This attempt to summarize the process of design engineering appeared in Nomadness Notes #23:

“A lot of the work of the past month has gone into mechanical design — this is one of those wondrously complex projects in which electronic component choice affects gross morphology, which in turn defines constraints that affect the choice of electronics. Such psychological race conditions can only be resolved by tweaking the granularity knob until the correct solution congeals in a flash. Put another way, I form a fantasy of the desired results and allow input variables to float until an unanticipated combination satisfies the fantasy-comparator, pretriggering a snapshot of the conditions that yielded it before accumulated pondering-propagation delays introduced conceptual drift. (This is not the design methodology you read about in engineering textbooks, even though it’s a good summary of life in industry. Most textbooks promulgate the myth that structured methods and sequential procedures will get you there. But beating trade-offs requires inventing new rules to break, not bumping into the limits imposed by old ones.)”

So much for the philosophy of technoid noodling. Here’s a quick update on today’s details…

I spoke with Interlink about the DuraPoint, reporting on yesterday’s test and mentioning the posting I did about their product to rec.boats. I complained about the heavy touch required of the two buttons, and he replied that they’ve heard that from about 35% of the people who have tried it. He’s sending a new one with “35% lighter touch” (the appropriate correction factor given the market research!), and we’ll return this one…

The local rep for SonicPro dropped by today and donated an alarm — a small unit designed to be attached with adhesive to a computer. Once armed with a 5-digit code, it makes an obnoxious noise when moved. It’s not designed for harsh environments, but may be a good thing to have around here. After playing with it, I suggested that they provide an option for screw-mounting into threaded inserts from the back. As it is, the only way to change batteries is to peel it off the host machine (non-trivial and potentially damaging), remove the foam adhesive (scrape, scrape), disassemble, swap batteries, find more foam adhesive (not supplied), and re-attach… not exactly convenient. I told him that many users would not bother with all this, and urged an alternative solution in their next revision. Otherwise, it’s a pretty cool product, and retails for $69.95.

Drew of Nelson/Marek spoke with Matthew at Current Designs today, reporting via email: “He has no hydrostatic data, but is going to call his suppliers to get as much info on the laminate properties as possible. This should give us some idea of the strength of the kayak…” I also spoke with Matthew and requested H-channel PVC extrusions for both boats to simplify the attachment of our custom decks (after fitting and sealing, the sections are internally glassed together — H-channel is not terribly structural).

While working on the inventory this evening (stretched out on cushy chairs in the new library lounge… nice), I sidetracked myself to deal with the gear stowage issue. Apart from ready-access bins near the cockpit (foul-weather gear, safety equipment, etc.), long-term storage in the forward segment, and personal/camping/cooking in the aft segment, there will have to be some sealed boxes, like Pelican cases, integrated into the rackmount system below. We’ll design the rack system to support built-in enclosures for equipment as well as a dozen or so removable cases for such collections as:

o Hand tools and mechanical hardware

o Electronics test, anti-static, and prototyping

o Electronic parts inventory

o Paper documentation and microfiche

o Sextant and manual navigation tools

o CD library

o Floppies, backups, and computer supplies

o Medical kit (apart from abandon-ship bag)

o Mechanical spares

o Batteries, charger, flashlights, etc.

o Office, files, documents, pens, and the like

o Essential books and directories

Andrea Woo went shopping this evening and picked up the HELLO badges for the meeting, but no luck on the scale. James Gerken dropped by and got about halfway through the CD-reorganization job. And Connie Weyhenmeyer spent a couple of hours working with me on the philosophical intricacies of aquatic nomadness.

TJ Tyler and Jim Effros also met here today to discuss management issues — I think we now have two of the three people needed for the triumvirate. I still need an ECE person as soon as possible, 5th year or graduate, to handle the largest of the three major project disciplines. We’re slowly establishing protocols and strategies for working most effectively with a widely-diverse group of volunteers, some motivated by course credit, some by pure technical curiosity, others by the fun of working on a shared project. This will be a good topic for open discussion next Saturday. (DON’T FORGET: put this on your calendar! Noon on November 6 at EBU-1 room 3325…)

Speaking of events and dates, I’m giving a talk in CSB-001 at 6:00 next Wednesday (Nov 3). This is an ACM meeting — contact Adam Sussman, my*****@****om.com, for more details. BEHEMOTH will be there, enjoying the attention but muttering to himself about stupid boats.

Finally, my friend Jean Polly in New York sent a birthday/care package consisting largely of chocolate… but the real gems were George Winston’s Summer CD and, most notably, The_Bridges_of_Madison_County, an incredible book by Robert James Waller. It’s one of those tales that clears out the cobwebs, affects your world view, provides the emotional control-alt-delete that we all need now and then, and makes you wander concrete hallways playing the flute until It’s All Been Said. Recommended. Highly.