Meet Datawake

Hello from the new floating lab! For nearly a year I was immersed in the sale of Nomadness (steel Amazon 44 sailboat) and the acquisition of Datawake — simultaneous exhausting projects involving boatyards, surveys, fractal to-do lists, complex logistics, and two wonderful guys who made boat buying and selling uncharacteristically pleasant (without brokers, and still friends after it’s all over!). Now I am again deep into nautical geekery, and have been living aboard since the first of February 2016.

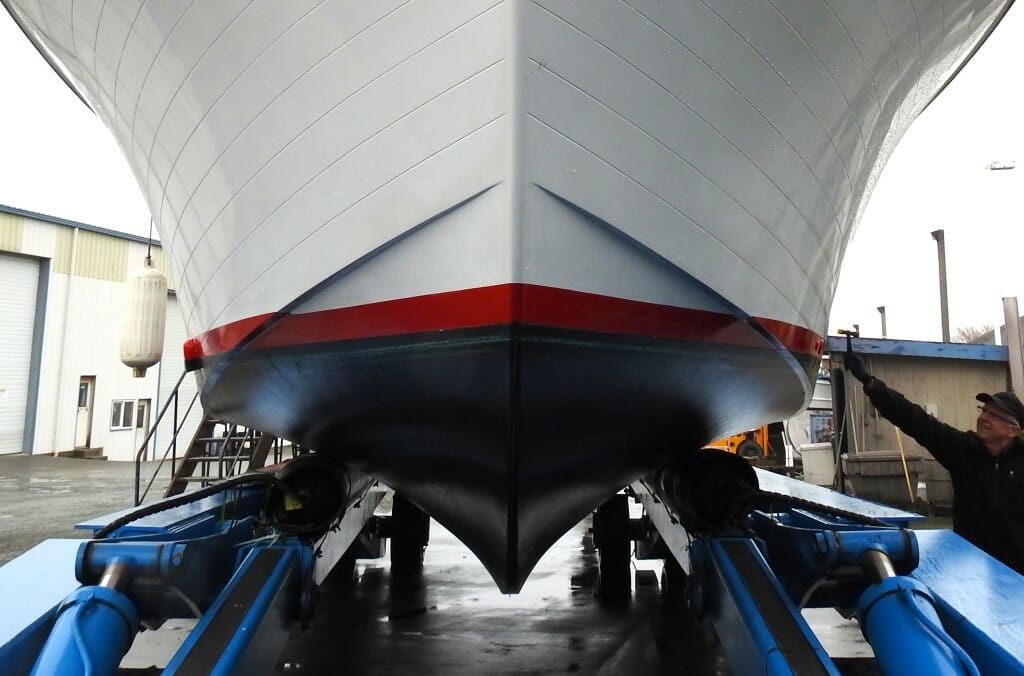

Before I start writing in detail about individual projects, I should set the stage with an introduction to the ship. Datawake is a 50-foot Delta power boat that was designed by Lynn Senour (who later designed the Nordic Tugs) and built by Delta in 1974, after which Vic Franck finished it as a yacht… here are photos of the boat from that era. Delta Marine still exists and now conjures luxury mega-yachts, but this is from their early years of building high-speed charter boats for harsh Gulf of Alaska conditions.

This is a semi-planing hull, and the cruising sweet spot at 2150 RPM with pyros at 900°F is around 17 knots… although she can hit 24 at wide-open throttle if you want to empty the 700 gallon diesel tanks as quickly as possible. The engines are a pair of Cummins VT-903 turbos, and at the efficient part of the power curve she burns about a gallon per mile. In displacement mode, she’s not bad at all, with a hull form that moves easily at “trolling speeds,” though I’m told to avoid the 12-15 knot range. Maneuvering is easy with the Micro-Commander system controlling the twins, and there are hydraulic stern thrusters just in case. I’ll have lots to say about all this in future posts; I dream of an electric hybrid system that will let me slip quietly out of a marina without the noise and smoke of cold vintage diesels… but that is way too much to think about now.

The previous owners took excellent care of the boat, and it shows. She has some decidedly vintage systems like a 32-volt house bank and an ancient Webasto furnace that sounds like a jet engine, but everything is solid. Even the old nav instruments work beautifully, like a classic Apelco spinning-arm sounder from the sixties. (This 1965 ad, published when I was in 8th grade, proudly describes it as being “all-transistor.”)

Now, a half-century later, I am sitting on an old boat packed with technology including 20 terabytes of storage, 3D printer, software defined radio, and wicked-fast computer with 27-inch monitor… but under all this blinky goodness is a solid nautical substrate that can take a lot more abuse than I ever expect to throw at it. That’s what tipped the scales (literally, at 25 tons) versus newer boats within the range of my Nomadness-sale budget. Hull layup is fiberglass woven roving about an inch thick, the stringers carry 7,000 pounds of engines, and house fabrication is glass over ply. There is a 15-kilowatt Onan generator under an afterdeck spacious enough for a small hot tub, and the upper deck (with flybridge) carries acrane-launched Achilles RIB (rigid inflatable) tender with 15 HP Honda… though the plan is to park that on the swim step with Weaver davits and fly the Microship instead. Almost precisely two years ago, I posted: The plan is to … integrate a capable electronics lab using the existing 19″ rack gear I’ve been developing for Nomadness, stuff a piano somewhere, and live aboard full time with Microship perched on the roof amidst a thicket of antennas like a geeky caricature of a megayacht with a helipad.

It took a while to find the right substrate, but that is now happening. Let’s take a quick stroll around the boat to set the stage, starting at the most important spot… the food lab. (I’ve been calling it this for a while, then discovered an absolutely wonderful book by that name… it easily made the cut for precious bookshelf space aboard, and I learn something every time I open it.)

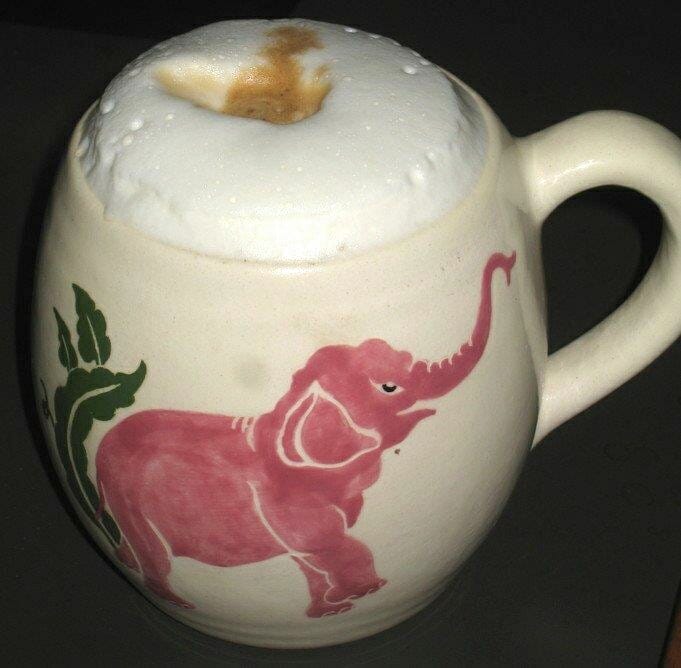

In addition to built-in basics like a classic Frigidaire stove and domestic-scale fridge (along with a useless trash compactor and a top-loading dishwasher), the galley carries my lovely Breville espresso machine and an Instant Pot pressure cooker. The scale of the space is just right, and I’ve been limiting the tools to those that I use and love… there is no room for the usual cruft that accumulates in cabinets and drawers. It’s only been 2 months so there is yet a bit of new toy syndrome, but so far I’m managing to keep the space tidy, even cleaning dishes and countertops after every use. (Ex-girlfriends reading this are exclaiming, “who the hell are you, and what have you done with Steve?”)

By the way,those shades are cordless “top-down bottom-up” units from blinds.com — and they are wonderful, pulling up conventionally or down from the top to provide a view of the world without exposing the details of blinking equipment racks to dock walkers. Isabelle can enjoy her morning duckwatch, and I don’t have to be shy whilst galumphing around in a bathrobe with my latte.

That galley photo above was taken from the middle of the lab region looking forward… now let’s take a few steps in that direction and then turn around:

This is not yet complete, but is getting there; I still have to build the “roof” of the console, which will carry studio monitors, video screen, and random small devices that would be a pain to panel-mount. That’s Isaballast in the blue recliner… her job is to eat as much as possible and then nap there to compensate for the weight of all these machines that I’ve been dragging aboard.

Future posts will go into lots of detail about what’s inside that 60U of rackspace (link is to detailed mid-2017 article), how the desk was built and integrated with the ship, the lab instrument suite, ergonomics, network architecture, and lots of other topics… but first we need a high-level overview. I am designing this to be the control console of my life’s toolset, and that requires accommodating six major categories:

Computer Workstation – Probably the spot where I’ll spend most of my time, this occupies the wing of the desk, bounded at the right by a little teak-edged demi-wall that isolates it somewhat from the passage to the afterdeck and encapsulates a thigh-bruising corner. Because I’m tired of cursing every chair I’ve ever owned, I finally broke down and invested in an Aeron C with Engineered Now H4 Headrest (presumably the last chair of my life), and the keyboard/trackpad are on a 3M pull-out tray with lots of tweakability. The Mac’s Thunderbolt display is flanked by a pair of Fluance speakers driven by a Fusion marine stereo… and the various peripherals are located nearby (laser and label printers along with ScanSnap atop the file cabinet to port; flatbed scanner with VueScan atop the toolbox to starboard; 11×17 printer for schematics up in the pilothouse).

Lab/Tinkering – That same spot does double duty as the Zone of Hackage; this is the desktop with magnetic fixturing that was fabricated for Nomadness, and I’m working on a set of tools to take advantage of this. When in this mode, solder and hot-air rework stations come out from hiding under the desk, and the monitor is pushed back to make room for messy stuff. This is augmented by the tool cabinet and test equipment in the adjacent racks selected after obsessive research (triple-output power supply, oscilloscope, multimeter, and waveform generator), turning that inside corner into a very compact and capable “makerspace” for the circuit-board projects ahead.

Ham Shack – The blank panel in the middle of the console is about to start seeing some milling action… this will house all the communications gear that has been on the shelf for too long along with the new Icom 7300. The operating position provides microphones, CW key, RF routing, and control panels… along with three SDR (software defined radio) environments and digital modes including PACTOR. Lots of station updates in this October 2016 post.

Piano and Recording Studio – Directly under the long section of the desk will be a 52-inch drawer for the Kawai MP7 digital piano… which is why the studio monitors and audio tools are centered on that region. I’ll put the pedals and looper board on a little slide-out unit, and the sub is back in the corner under the tool cabinet. The throne for this zone is a Soundseat that provides more freedom of movement than the Aeron. Major update here… all MOTU now.

Video Production – The console provides a backdrop and production toolset for my upcoming YouTube series… with the rack on the far left mostly devoted to video switching and monitoring for the dozen or so cameras around the boat. This integrates with Final Cut Pro on the Mac; I’m a total newbie at that, but there’s a huge backlog of material as well as the ongoing geek narrative aboard Datawake. Stay tuned, as they say in the idiom.

Ship Development Tools – Finally, there is all that other stuff… things that need packaging, power, connectivity, serviceability, and some kind of user interface. These are distributed throughout the console and the space below, and include a smart UPS for the network, Shacktopus for communications and backup power, a gigabit switch that handles all the network devices around the boat, WAN tools, a Synology 16TB NAS running multiple apps like backups and local web services, video switcher and related hardware, firewalled Intel NUC for all the things that want Windows software, panel-mounted iPad for admin interfaces and sheet music, small Raymarine E7D multifunction display to reflect nav tools, a dedicated server with offsite mirroring for all the security camera feeds, radio interfaces, the data collection engine, and dozens of other bits of gizmology of various scales. This is the glue that holds all the rest together, and will make this console feel like the hub of my life. The photo shows some early development before moving the console hardware aboard; that’s Steve Mitchell chasing a DHCP oddity in an earlier version of the Pepwave firmware.

OK, we’ve been ogling blinkies long enough! Let’s continue the tour of the boat. Between the passage up to the pilothouse and the pantry to starboard, there is a door that leads down to the engine room…

That’s a lovely little benchtop mill from Little Machine Shop, which uses the same R8 collets as my old Bridgeport (See a Dec 2017 post with more photos about the boat’s machine shop). This is my third mill, and I’m keeping the name that I first gave my old Rockwell back at the Bikelab… Cecil (Cecil be da Mill). I am indebted to Bryan Hoyer of Northwest Digital Radio for making this possible, and look forward to fabricating some parts for him… this machine is really sweet, and just the right size for a boat. I cut that riser base from part of the old laminated Nomadness desktop, and will be adding wall-mount holders for tooling and other accessories. The machine will also get a digital readout (DRO) to simplify use.

(An interesting little relic is on the wall in the upper left corner; that was made for me in the ’80s by Daniel Kottke, Apple’s first employee, back when I had the Bikelab at Sun Microsystems. It uses a PIC to cycle through some geometric patterns, then scrolls NOMADIC RESEARCH LABS.)

The little dark area to the right of the machine bench is about to get my pancake air compressor with retractable hose reel; I tried putting parts inventory there, but it’s a pain (a cabinet of Stanley organizers will be upstairs along the galley counter, and bigger items are finding homes in various corners). Turning around, we see the other magic fabrication tool on the boat… a LulzBot Mini 3D printer. This thing is a marvel, and in this photo it is just presenting a Raspberry Pi box that I downloaded from Thingiverse. (If I can find the space, I’ll get the new TAZ 6… sometimes the 1-foot cube build envelope would be very nice!)

Like most 3D-printing newbies I quickly tired of tying up my computer during print runs, so I hung a Pi on the side, installed OctoPrint, fumbled through the initial learning curve, then just started thinking of it as an appliance. It’s now a relatively short path from idea -> drawing -> STL model -> gcode -> custom plastic part… and there is a huge range of available filaments that allow fine-tuning the material according to the requirements of the job.

OK, enough with shiny electronic things… let’s poke our heads into what some trawler pilots call the “Holy Place.” This wide-angle photo is by Steve Mitchell:

These beasts are frankly somewhat terrifying to me… they were built in the early ’70s, and one of the jokes on the Boat Diesel forum is that any mechanic who knows them well is too old to clamber around in an engine room. That may be a bit hyperbolic, but carries a grain of truth… along with the rarity of parts (although a variant of this was in the Bradley Fighting Vehicle). The counter-argument, which is also valid, is that they are built so solidly that with reasonable care they will just keep going, and going, and going… probably longer than I will.

Of course, they are sleeved, with means that coolant additives are essential… and getting any work done on them is expensive. But even though they intimidate me with their implacable might, nautical geezers nod approvingly and offer bits of wisdom about running them every so often and casting off the dock lines.

Backing slowly out, careful not to bang our heads, we see the Webasto diesel furnace and cable drop from the pilothouse. Not shown in the photo, just out of frame below the air duct, is the huge battery bank and a big modified sinewave inverter (yah, I ran an FFT on it… not pretty).

Popping back up the steps to the lab, then turning forward to take a few more, we find ourselves up in the pilothouse. Directly above the furnace, we see an open space with a sprawling desktop for charts, along with those vintage-but-solid nav instruments I mentioned at the beginning. Here was the view during the delivery voyage from haulout in Anacortes to her new slip in Friday Harbor:

(You might have noticed, if you clicked to embiggen, that pyro #4 is low; that worried me, but is just an intermittent connection.) The circuit-breaker and metering panels are just out of frame to right, the area behind me when standing at the helm has become a library and workspace for large document projects, and I’m adding a small deployable pilothouse table to allow dinner-for-two (with a view!) without violating the cardinal rule about beverages and slurpy things next to electronics and pianos.

As to the cabins forward, I’ll post photos of those another time… they’re way too messy now. Heading toward the bow takes us to five additional spaces:

- Sleep lab to port, with a flat platform bed that desperately needs to be replaced by an adjustable substrate to give my back some relief, though I’m not looking forward to the inevitable woodwork. This has private head and shower compartment, and the arrangement of cabinetry around the bed allows iPad, video, stereo remote head, speakers, health tools, and other devices.

- Forward guest cabin, with two berths and an en suite head/shower… a space with nice views port and starboard, along with an overhead hatch and some very tempting drawers that would sure solve my inventory-stowage problems.

- Laundry room to starboard, with a dryer hose that is easy enough to access that I’m designing an actively vented cat box with carbon filter, inline fan, and selectable damper… along with a cat door from the passageway. She currently has her facilities in the guest shower, which makes the space somewhat less inviting and requires a shuffle when visitors stay over.

- Huge hold below the hallway, with freshwater tanks and lots of stowage.

- Waste-processing hold below the forward cabin, which needs surgery ASAP to replace the tiny holding tank associated with the ancient and anti-social SanX system that is not in use. Damn boats. It always comes down to sewage projects, doesn’t it?

There’s a lot more to see… but I think this is enough of an introduction to the new ship after my long blog-silence! Now that we have established context and have a solid server, I look forward to frequently posting details about all the projects. There is no shortage of material… or pixels.

Cheers from Datawake,

Steve

You must be logged in to post a comment.