Microship Status Report 129

by Steven K. Roberts

Camano Island, Washington

April 4, 1999

“To work on tomorrow’s technology today, we get up 20 hours before everyone else.”

— Bob Stuart, SpinFin developer and Microship structural fabrication guru (photo above).

Piloting the Microship

The hidden journey continues… the seemingly endless marathon that lies behind the adventure itself. In my heart we are prowling backwaters, floating through serpentine canyons, slipping along coastlines and stopping at every whim to languish on sun-kissed beaches. Always the dream… the driving motive behind slowly unfolding complexity that boggles and confounds at every turn.

It’s the hidden journey that fills our days and nights, launches us on epic quests for esoteric artifacts of late 20th century technology, and entangles conversations with non-sequiturs:

“My driving test is Tuesday,” quoth Lisa; “I need to practice parallel parking.”

To the tangled mind of one immersed in conflicting design requirements, a perfectly contextual response is: “You know, I’m getting worried about the waterproof connector requirements of the chord keyboard interface, so I’m considering serializing the whole mess and piping it through IR… or maybe… hmmm… I wonder…” whereupon I zone out while contemplating the mad idea of embedding a Palm III in the starboard steering pod while Lisa is left standing, an italicized interrogative thought bubble over her head, wondering how to drag me into town for some driving practice. She’s amazingly tolerant, but I do push the envelope sometimes. (BTW, she did pass the test… Lisa is now freer than ever.)

Actually, that bit about the Palm is no joke. It’s too early to say “this is the plan,” but the problem is this: the two hydraulic armrests I discussed in Issue #128 are now being fabricated, with the Clippard cylinders attached to Swiss-cheesed stainless channel and their rods terminating at the end plates of 2x4x18″ molded fiberglass covers that ride on drawer slide assemblies. The idea is to attach pods to the forward ends of these, with embedded pushbuttons and Interlink force-sensing resistors of various flavors to provide all the user-interface widgetry required by the various console computers. (One switch “targets” the chord keyboard and pointer to the Mac, nav PC, or Linux environment as needed.)

Alas, all this involves a fair bit of cabling — along with thruster controls, push-to-talk, and other random switches… some 12-16 wires per side. These have to survive 6″ of cyclic linear travel within the armrest assemblies, terminate to the wiring harness in a busy and wet cockpit area, and be reasonably noise-immune. Connectors are bad things, as are long parallel TTL-level data runs. Hence my non-sequitur about serialized IR interfaces… this has really been bugging me, another detail that is somehow in the critical path ‘twixt here and going for a nice sail.

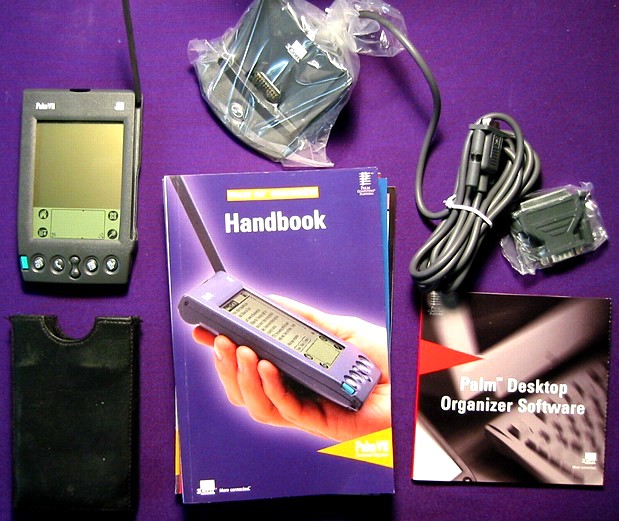

Bt ya know, once you start thinking about a robust little power-efficient embedded processor with an IrDA port and well-engineered user interface, the obvious question has to be asked: “Does this already exist?” (If so, it would be mad to reinvent it.) That’s why I’m considering using a Palm Pilot embedded in the starboard rudder control to handle the whole user interface of the Microship — and, conveniently, be a useful tool even when the big iron is OFF (Lisa and I have quickly gotten addicted to them, and are carrying a lot less paper around). I’ll keep you posted on this, after I finish finding out if it’s feasible — there are some thorny packaging considerations and sticky integration issues to resolve.

Any Palm developers out there wanna write an app that turns the display area into a trackpad and sends standard serial mouse and keyboard (Graffiti) data out the IrDA port? I already have the Silicon Valley Bus Company “Keystone” to convert PC-standard kbd/mouse data to ADB for the Mac, so this could become the long-needed WHIP (Wireless Human-Interface Platform). The other end of the IR link has to be smart enough (another Palm?) to differentiate between the mouse data stream, text entry, and normal syncing. Any volunteer Palm wizards well-versed in CodeWarrior and up for a challenge?

Landing Gear and Thruster Update

Pushing as we are toward the PCA Tour (Previews of Coming Attractions), the critical issues right now are those that get the boat on the water; the foregoing is of immediate interest only because it affeblobscts the physical structure beneath it. Most of our current work is far removed from the rarefied realm of user interfaces and embedded communication protocols.

The biggest project at the moment is the landing gear… a design and fabrication nightmare so daunting that we might never have begun it had we possessed a shred of prescience. Amazingly, however, there seems to be hope.

I first reported on this back in November, ruefully observing that Bob had already spent over a month on the design. Well, that was just the beginning. By February he had completed detail drawings at home and conjured a bill of materials… so we’ve been haunting scrap yards, Boeing Surplus, and (best of all) Metalshorts, with a long list of obscure sizes of 6061 aluminum tubing. Even here in airplane country, this is non-trivial… big distributors want to sell you 12-foot lengths even if you only need 6 inches of something. Meanwhile, between working on his BiCanoe and feeding Miss Piggy, Bob has been molding the landing gear pivot bearing tubes and hogging out gaping holes in the boat to accept them.

One of the more interesting problems was the suspension — with rigidly mounted struts, a hard surf landing could be a catastrophic demo of why one should never point-load fiberglass. Bob specified 8″ of travel, with about an inch of initial deflection at a static load of 250 pounds per wheel, a range of gradual softening, and ability to handle 4G before bottoming out. We spent quite a while chasing gas springs, complex Citroen-style hydro-pneumatic systems, and other corrosion-prone assemblages of dissimilar metals… then homed in what came to be affectionately known as the “blobs.”

It seems that a material known as DuPont Hytrel has dramatic and repeatable energy-absorbing characteristics — especially if molded into shapes that combine deflection and compression. The material is used in industry for such things as crane bumpers, and Miner Elastomer Products has developed a complete product line with a wide range of force-vs-travel curves. Miner quite made our day by donating a passel of parts (GBA-2 and GBA-103S) which will be strung like beads onto alignment tubes, constrained from drifting out of column by traveling polycarbonate guides, and enclosed within the pivoting anodized aluminum struts.

As if all this were not enough complexity to portage a canoe, we also have to rotate the Seitech wheels 90 degrees upon retraction for stowage under the solar panels, align the aft pair along the boat’s axis when deployed, allow the forward set to caster, effect deployment and retraction from inside the cockpit, and add brakes! Thanks go to Motion Industries for being helpful and quick with the Torrington and Timken bearing order, to Omni Packing for donating a lovely piece of felt that will be fashioned into seals to help keep abrasive sand out of the struts, and our mole at Boeing for a beautiful midnight engineering job cutting and facing the aluminum tubing parts.

More on all this as it continues to develop, but we’re getting close — Bob is building precision jigs (holding the Medite parts within .1 degree) with the planer blade on Jack the Ripper (our new table saw), fishmouthing the tubing with 2.5″ and 1″ hole saws, and preparing to hand the whole mess over to the TIG Shop here on the island for welding. All we need now is a machinist to turn a hunk of 2″ aluminum rod stock into bearing assemblies, and we can start assembly.

Meanwhile, another critical item needed for our next on-water test is the electric thruster — a Minn-Kota 42EX with PWM controller interfaced to one of our FORTH nodes by Tim Nolan. After rejecting a few fanciful mounting ideas, we settled on a scheme that allows it to pivot down (supported by its steering motor) from the afterdeck just inside the arch.

Bob-the-aluminum-sculptor took a big chunk of channel, turned it into a lovely weight-minimized structure, and built up the deck into a shaped pad to accept it. The battery box is mounted on a glassed-in floor against the forward bulkhead, so once I finish the steering pods and the landing gear are miraculously attached it will be time for our third test sail… an amphibian trimaran with pedal and electric auxiliary propulsion.

At that point, we’ll mount the Solarex photovoltaic modules… we’ve just finished setting up the vacuum-bagging facility, designed the folding and interconnect systems, and are working with Composite Materials to track down suitable high-temp epoxy (solar panels can get hot in enough in operation to soften the West System resin we’ve been using throughout the project, especially when insulated by a foam-core substrate). The basic layup is a top layer of 4mm okoume marine ply sandwiched in 6-ounce cloth, a core of 1″ Divinycell PVC foam, and a bottom layer of 10-ounce cloth… all framed by fir to support hinge hardware and wiring channels.

To California with a Tracker

The speaking biz has a lot to do with keeping this boat afloat, and last month was occasion for another Mothership jaunt… to Monterey and points in between. I spoke at MBARI, did a keynote for a Cabletron event, gave an informal presentation to the Palm engineers at 3Com… and we crammed a whole slew of interesting visits (with Java the cat, of course) into a 2-week round trip.

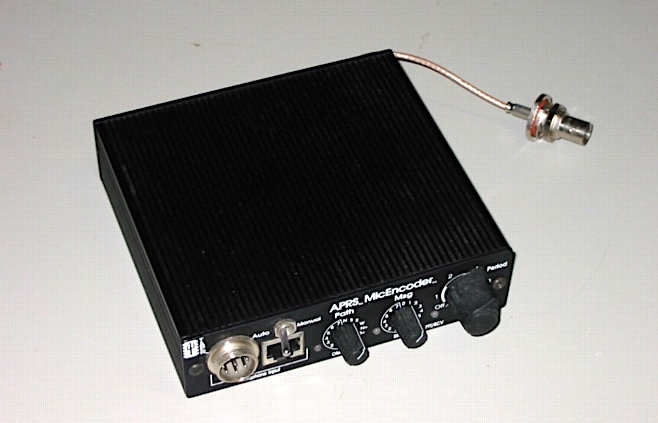

This trip had a technological spin as well — a chance to test the TAPR Mic-E tracker. I mentioned this briefly in our last update: a box that lives between a GPS receiver and a ham radio transceiver on 144.39 MHz, transmitting location beacons at preset intervals which are then forwarded by a network of digipeaters. Hams running the APRS (Amateur Packet Reporting System) software can watch a dynamically updated map of everyone’s movements, and the combined data stream is available via telnet. Naturally, there’s a layer on top of this — Steve Dimse, K4HG, has put up a beautiful website that displays three different zoom levels of MapBlast windows to show the location of any APRS station that has successfully transmitted a position report within the past 8 hours.

There’s an active tracker subculture out there, so I was fortunate to have quite a bit of help when interfacing the Mic-E to one of my Motorola VP Oncore GPS receiver boards (piggybacked and housed in the same box). It was fairly fiendish, as such things go, with the trickiest part being the fact that the GPS wakes up in Motorola binary mode. Getting the serial port to speak vanilla ASCII requires sending an obscure command string as one continuous burst… not from a keyboard. Easy to do once you figure out that it’s necessary!

And then, after determining that my building doesn’t move beyond the accuracy degradation induced by Selective Availability, I stuffed it all in an old Cannondale pack, kluged it into the truck with a cigarette lighter plug, and mounted two roof antennas (active GPS patch and Larsen dual-band whip). And we were off.

APRS is a strange sort of amusement, and changed the flavor of the trip. Like most geeks, I fretted over the technology — fiddling with transmit interval and forwarding path in areas where I wasn’t sure of coverage. But it was open-loop anyway, so I forgot about it after a while… until I started seeing the effects. While in the Monterey and Moss Landing areas, I got email from Mike Setzer, a friend here on Camano Island, telling me that 11 minutes ago I passed his old elementary school. When we dropped by to see our friends at Netcetera in Boonville, they said, “we lost you in the mountains after you left I-5, but then you popped up in town, right in front of the cafe.” And when we visited Steamboat Ed in Sebastopol, he wondered aloud why we had doubled back on Kennedy Road in Petaluma after visiting International Medcom. Net voyeurs, watching our every move… this will be fun on the Microship as long as we have no reason to hide <grin>.

Next road trip: Colorado Springs and Boulder in the first week of May… we’ll be running the tracker again. Ideally, we’d move to the standard HF APRS frequency (10.151 MHz) to get coverage through the vast unpopulated areas, but I doubt we’ll have mobile HF in the Mothership by next month.

Talkin’ About the Weather

You know the frustration of seeing something over and over, yet not really understanding it? With the infinite range of learning curves always in my face, this is a too-familiar feeling, and one of my perennial favorite mysteries has been the weather.

Of course, I’ve had little trouble pickling out basic go/no-go advice from NOAA weather radio and have always taken it on faith that deepening low pressure means bad weather a-brewin’. But it takes a lot more than that to make intelligent decisions about sailing tiny boats, and our opportunity arose in the form of the Marine Weather seminar, put on by Ocean Navigator School of Seamanship and brilliantly taught by Michael Carr (aided by Lee Chesneau of the National Weather Service).

Lisa and I, along with about a dozen other sailors, spent two days in total immersion with these weather experts — learning to read 500 millibar charts, interpret IR and visible satellite imagery, understand the tracking of hurricanes, predict the effects of jet stream short-wave troughs on surface events, and make practical sense of the wealth of real-time knowledge available via the Web, HF weatherfax, direct satellite transmission, NAVTEX, and voice bulletins. It was at once exhausting and enlightening… the chicken tracks of forecast charts suddenly revealed in the dizzying splendor of a 3-dimensional dynamic mental model of heat and air flow around the earth. If you are off on a sailing adventure, I recommend this seminar without hesitation… I’ve tried reading books and articles about the subject, but this was infinitely richer.

Speaking of the weather, one of the most exciting additions to the suite of applications for the Microship’s nav PC is now confirmed: the SeaStation 2000 by OCENS. This magical product consists of a sexy quadrifilar helix antenna for the afterdeck, a receiver in a tiny box (which also, as a bonus, inhales HF weatherfax), a PCMCIA interface, and some magnificent software. I’m sure I’ll write a whole rave about it once it’s fired up on the Microship, but just as a teaser… imagine being able to download live visual and IR images from low-earth orbiting NOAA satellites (which arrive like fax images, as the birds transmit live raster scans throughout their full polar orbits). Once an image in the system, you can map the gray levels to colors, scaled however you like to highlight cloud tops, water temp, etc. The Gulf Stream, for example, is revealed in dazzling clarity, complete with eddies… and it accepts NMEA data from GPS so you can see your own location in the context of current weather conditions.

The beauty of this is that it doesn’t require a net connection to give live strategic weather data, but if the Web is available, SeaStation can also handle the high-res Satellite Active Archive images posted by NOAA

Acknowledgments and News

First, thanks go to International Medcom for updating our Rad-Alert radiation monitoring tools with the latest models — allowing observation of both air and water levels. The products are mature, low-cost, and easy to use… we stopped in a pancake house on the way back to the lab and noted that the brightly colored ceramic tile around the windows was emitting twice the background radiation (much to the consternation of our waitress!).

While in Silicon Valley, we visited Steve Sabram of Datastick — whose amazing new product by the same name was just released. This plugs into the docking port of a Palm organizer, and provides extensive 12-bit data collection and analysis capability using up to six external analog sensors along with a trigger and ground line. This is an extremely cool device, and we’ll put it to heavy use during the sensor development and calibration projects — and will use it alongside our HP Logic Dart and Fluke instruments as a key R&D tool in the Microship on-board lab.

The California trip was our first “field” use of the new Motorola license-free TalkAbout radios, which are now always in our packs. These things are incredible: jewel-like packaging, unbelievable battery life, excellent range, and good audio. Lisa and I already find them indispensable, and turn them on whenever we’re out of mutual earshot. Motorola sent us a care package that included various TalkAbout models and accessories, two base units, and GMRS handhelds… so we’re pretty well covered for voice communication in addition to our various ham radio tools! We passed along our old units to Skip and Kelly Volkmann, nomadic friends with many a mile under their wheels and more coming…

Thanks go to DeLorme Mapping for Street Atlas USA and Eartha… I’ve been a devoted user of their paper atlases for years, but have never gotten to know the CD-ROM version. Friends in the APRS community rave about it, so this will be one of the apps in the Microship’s Nav PC.

Speaking of computers, we’re on the verge of picking up a couple of Macintosh G3 laptops for our personal workstations, and I’ve been using a hand-me-down 540C PowerBook from Warp Speed Imagineering for off-site writing and email. On the other side of the philosophical fence, a used Pentium has been donated by Matt Hixson for lab Linux development (even though he has moved to Idaho, he’ll be doing a lot of the development remotely, especially if we manage to get a 24×7 net connection set up), and Brian Willoughby continues to be involved heavily in designing the Microship server code. The AST Server 486 from Tony Loro will become the Nav PC development engine, and while we’re at it, thanks to Eric Johanson in Redmond for a couple of CDROM drives so we can install code on all these puppies!

In pointer-update news, Addenda Electronics, makers of the slick little Rosetta Stone adapter that allows us to control the Sony 8mm VCR with simple serial RS-232 commands, now has a new site:

In the media department, there’s only one to report since the last issue — the March, 1999 issue of Telecommute magazine. We’re part of an interesting survey piece on “X-treme Telecommuting,” and share the spotlight with some of the other technomads out there: Steve and Jason of “Pedal the Planet,” Almitra the PhotoGypsy walking across Australia, Mark Eppley of Traveling Software beaming tales and images from the top of Mount Rainier, and Sid and Kristanne cruising the US in Otto von Auto. Fun piece… and intriguing people:

And finally, before we close, I have a BIG question for the RF and ham radio wizards lurking on this list…

Antenna Design Challenge

There is no room on the Microship for a proper HF antenna: no backstay sloper, huge standalone vertical, or high-Q tunable loop. The tiny afterdeck, where I planned to mount a fiberglass whip or Outbacker Marine, is taken up with the Handar ultrasonic wind sensor and the OCENS quadrifilar satellite antenna. But we absolutely need HF capability.

The obvious solution, if at all possible, is to load up the 21-foot freestanding aluminum mast. We can easily insulate the rotating gooseneck so there won’t be any intermittent connection to an extra 8 feet of boom, and we can cobble together a connection between the two Delrin-socketed mast sections. But the problem is coupling to it: the mast rotates freely on two Delrin rings inside a piece of Teflon-anodized aluminum tubing, and has to be easily removable. We can’t just solder on a SO-239 connector.

If someone can solve the coupling problem with a capacitive lashup that can handle the nasty environment, they will achieve Geek Hero Status among our team of technical volunteers. We do have an automatic tuner that can be positioned nearby (the QST unit — but I would prefer one that uses latching relays to minimize DC power dissipation). I look forward to hearing ideas…

With that, I’m off to don my Purchasing Department hat and fire off a huge McMaster-Carr order. In our next issue, we’ll present an amazing discovery by David Berkstresser… waiting 2.5 months to produce this one left us with too much material!

You must be logged in to post a comment.