Microship Status 104 – SeXBAR Schematics

by Steven K. Roberts

Nomadic Research Labs

Santa Clara, California

May 2, 1996

THE SeXBAR IS ALIVE!

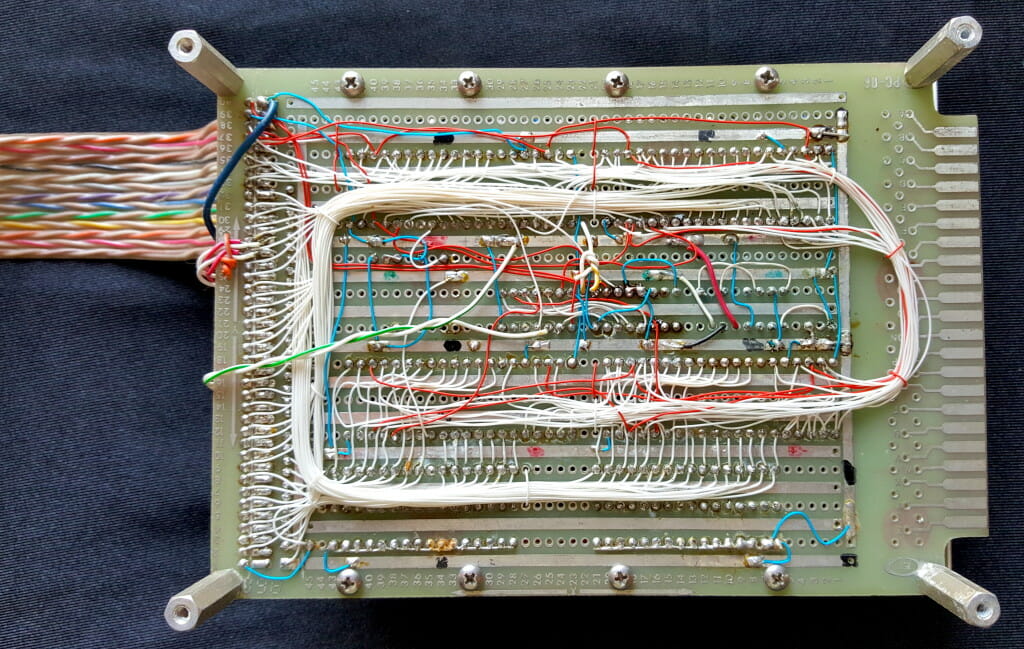

Ah, the simultaneous joy and frustration of debugging: the joy of finding that a suspected problem is OK after all and the frustration of having absolutely no new theories about why the damn thing’s still not working. This time around, we had the mingled surprises of a broken piece of #30 kynar deep in a point-to-point rat’s nest, a cabling error on an address bus header, and a software misconception — all affecting the same tests.

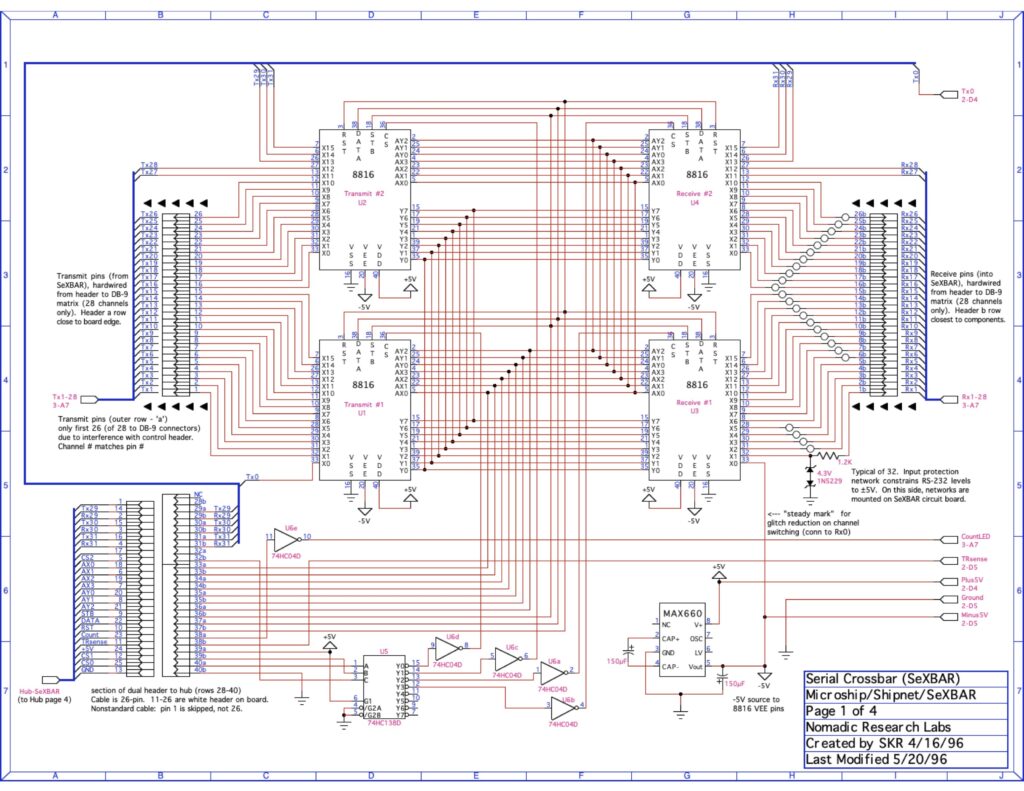

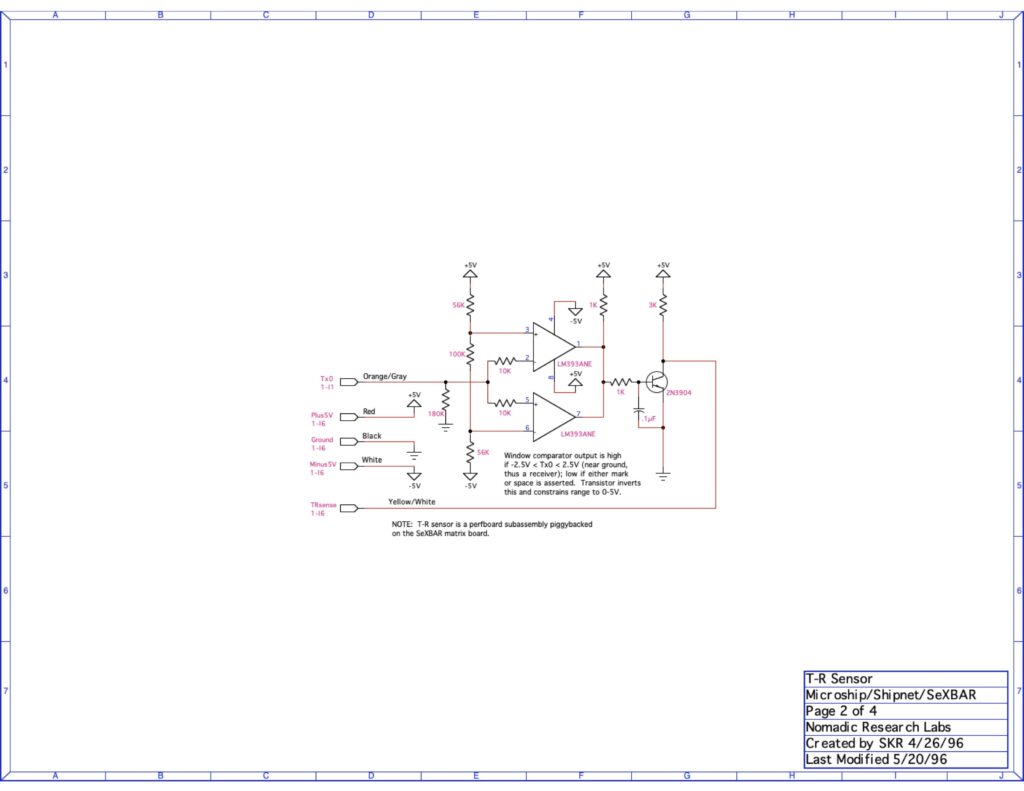

Most of the hands-on hacking in the past week has involved the Serial Crossbar, much of it in the incredibly tedious process of wiring 28 DB-9 connectors, each with three associated discretes nestled in heat-shrink and a twisted pair snaking through grommets to a header. I also built and tested the T-R sensor on a sliver of perfboard — a nifty little window comparator based on an LM393 that informs a Hub input bit about the polarity of any RS-232 channel connected through the network to Channel Tx0. This amounts to an arbitrary number of software-deployable null modem cables that are so far below the user’s awareness that some digging would be required to unearth the connection details… just as it should be!

I pretty well explained the function of the SeXBAR in issue #102, but I would like to make one more general comment. First, a couple of our regular readers have taken me to task for not making everything on board talk TCP/IP, accusing me of being “hardware-centric.” That’s probably a valid accusation in general, but I maintain that a 4×6″ board hanging off 12 port bits is a lot less hardware than the numerous processors that would be required to give every environmental sensor, remote-controlled radio, electronic compass, GPS receiver, modem, speech board, and serial LCD module an IP address. My approach does add complexity since there are two distinct networking environments separated by the FORTH Hub, but the one in question here is VERY low-level. In fairness, however, one of the mistakes we made on BEHEMOTH was attempting to link the high-level systems through this kind of tool also… and that indeed didn’t work very well. On the ship, the Macs, wireless manpack hub, and Internet gateway will all be on an ethernet LAN, presumably 10baseT.

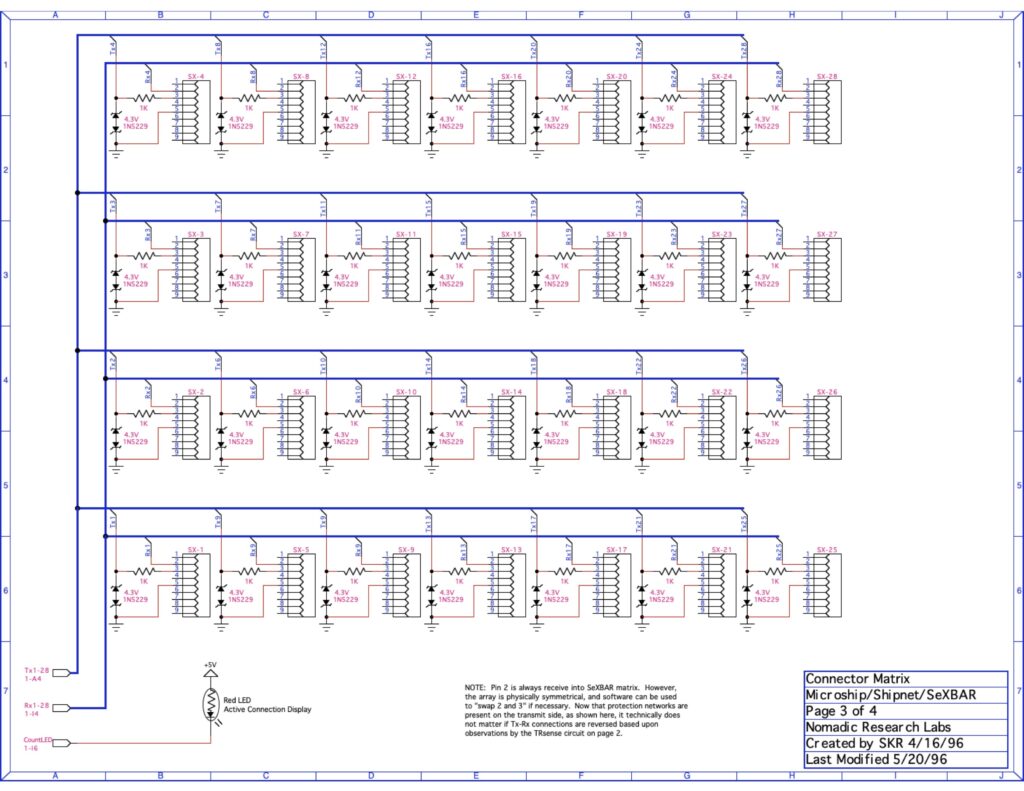

Incidentally, I mentioned in the last issue that SeXBAR completion was delayed by a temporary shortage of 4.3V 500mW zeners, since I hungrily gobbled up the last of Halted’s inventory of 1N5229s. The quest for these was an interesting insight into the range of resources in Silicon Valley: the awesome new Fry’s megamarket (all things electronic) had them singly bagged for $.69 each, while RElectronics had ’em for $.40. Faun made a run to the latter to pick up 40 of ’em and since I couldn’t make sense of the part number I tested them “just in case”… and they turned out to be the wrong voltage. Mark Moorcroft finally found what we needed at ACE for $.06 each. An 11:1 price range, all within about 5 miles. You do have to know how to shop around here, but it sure beats mail-order from the Midwest…

Anyway, now that the SeXBAR is done, my next move is to write a quick high-level word that basically calls the existing code twice to set up a bidirectional connection after first confirming the polarity of each device. The array handler and crossbar control code (based on the AuXBAR system) has been fully tested on all channels. This essentially completes the “Grand Central Station” level of the Microship system, with 64 audio channels (32 each in and out), 24 video channels (16 sources, 8 sinks), and 32 serial channels all interconnected under FORTH control. HyperCard guru Ted Kaehler of Apple has offered to help design the front end, so I’m sure it will be a lovely user interface!

Ship Documentation On The Web

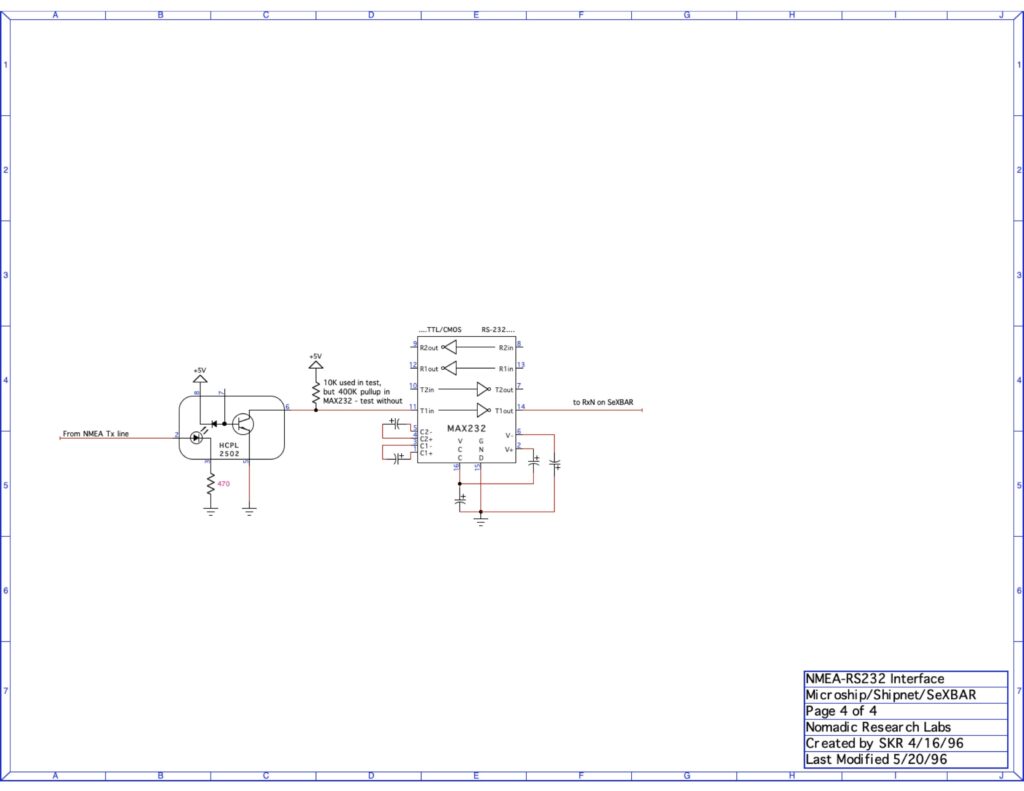

If you’re interested in knowing more about the Serial Crossbar, it is the first of the ship’s many subsystems to be fully documented on our web site. There you will find a 3-page schematic exported from DesignWorks, the FORTH listing for the driver software, a detailed text description, and a photo of the unit. I will gradually add all of the system documentation as time goes on, eventually collecting final versions into the Microship Technical Manual (both for my own reference and for sale, just as I should have done years ago with BEHEMOTH!).

Apprentice Quest

The massive, multidisciplinary scale of this project has made it clear from the beginning that I can’t do it alone, even with the aid of Faun’s capable handling of the office, Web site, print publications, and hydroponic garden. We had student help at UCSD and now have a number of volunteers assisting with everything from running around to pondering the network tools, but there’s still one major position to be filled.

What I need here is a broad-spectrum tech/apprentice, interested in everything, good at packaging, reasonably literate in a wide range of fields, hungry for experience, and free enough to make a lifestyle change without expectation of a salary package. (I can hear most of you chuckling already!) Seriously, though, I think the range of benefits could make this a win for the right person: world-class contacts with our amazing group of wizards and sponsors, highly marketable hands-on experience, exposure in the media, the amusement of being involved in an engineering project where the bottom line is fun, and the inevitable hand-me-downs and extra goodies from the lab. Depending on one’s lifestyle flexibility, we can offer assistance with overhead, but for obvious reasons we can’t really PAY, per se. Unless, of course, one of our sponsors wants to donate a person (or while we’re dreaming, why not a whole engineering team?) for the duration…

Anyway, if this bizarre notion excites you or might light a fire under someone you know who’s brilliant but needs to get off his or her duff and DO something, please let me know!

Random Updates…

Finally, we have a few news bits and thank-you notes:

First, my father back at my old Kentucky home, Ed Roberts, gets a hearty “THANKS!” for a cash donation that will significantly help offset the rigging expense. That plus the proceeds from the sale of the Fulmar almost gets us there. He’s in his 80’s, graduated from Swarthmore long ago as a mechanical engineer, and spent his career at General Electric designing refrigerators and ice cube trays. We need to get him on the Internet… he’s currently the only person in the world who receives these reports from us via a quaint network protocol that involves generating hardcopy, packetizing and addressing, gluing on a colorful receipt for the communications charges, and handing it over to an organization that physically transports it some 2,500 miles. I try to imagine the wonders of the Web from his perspective!

Thanks go to John Crump (whom I first met when he was producing Silicon Valley Report on KTEH-54) for putting in a number of hours scanning our sponsor logos. Faun is putting these on our Web site, and adding information pages for companies who don’t have their own. When done, every entry in our sponsor list will link to somewhere, either the company’s page or a local one that gives access and basic product info.

David Berkstresser and Mark Moorcroft are separately but simultaneously nudging the on-board trailer project along — Dave has CAD artwork for the frame and suspension structure; Mark has been researching the lightest and smallest possible wheels and tires that will handle the load. We may end up with 8 Honda Civic 13×5 aluminum wheels on stub axles, arranged in 4 pairs. All this is still preliminary research for the big question about whether this will fit and be practical, but we REALLY need it.

Sponsorship of the two 70-pound-thrust Minn-Kota motors from JWA Marine has been confirmed, and we should have them next week. The timing is good for integration into the first test configuration… which means we will soon be on a quest for batteries and charger.

This Saturday we’re off on a kayaking adventure — hooking up with the Cybercruisers in Redwood Creek for an afternoon. Someday we’ll arrive at a raft-up in a proper boat, but for now…

The Advanced Coastal Navigation class we’re taking from the Coast Guard Auxiliary has grown ever more challenging, with vector calculations for current sailing the most recent topic. The cruise exam, reputed to take 4-5 hours, is looming dangerously on the horizon.

Finally, let us have a moment of silence to mourn the passing of the pasta monopole, whose short but eventful life gave us a chance to test the tuner, make a few contacts, and even listen in on one of the Pacific cruiser’s nets. Now we know why they don’t make sailboat spars out of PVC <grin>… it’s hard to keep that stuff in column! Time for rev 2…

You must be logged in to post a comment.