Power, Console, Landing Gear, and MIMSY

by Steven K. Roberts

Microship Status Report #127

Nomadic Research Labs

Camano Island, Washington

November 19, 1998

“It takes a village to build a boat.”

— Tim Nolan, referring to the ever-growing volunteer population on the Microship project

Hello from the Microship lab! Lots of progress on many fronts… with two test sails now behind us, there is an unfamiliar sense of reality that is speeding the project forward as never before. I look at the boatlet perched on her workstand amidst the fiberglass dust and strewn tools, and see something graceful and alive, poised for launch.

Miss Piggy crackles heartily as she gobbles firelogs; the stereo pumps ancient familiar road tunes into this hastily-erected structure in the Camano Island woods. Pools of project detritus abound wherever you look: the zone of linux hackage in the corner, the FORTH hub and its nodes blinking away, the power management system sitting amidst bench clutter and a lineup of Fluke meters, Bob’s desk awash in landing gear drawings and mechanical gizmology spec sheets, a half-finished console frame model perched in the boatlab, Glass ‘n Goo World a mess of 10-ounce scraps and encrusted epoxy cups, metal bits a-glitter in the machine shop, the latest fill curing in the Region of Dust, bins overflowing with parts in the Hall of Inventory, and paper scraps all over the floor of the Media Lab from a recent publication project. My office is a mess; my desk, just like every time before, has entropically degenerated into a loosely coupled 3-D information space of overlapping piles despite my constant vows to get organized. Oh well. The anal-retentive in me sees it all as a mess to be cleaned up; the adventurer shivers with anticipation…

Power Management System – 1998 Peak Power Tracker

In our last report, Tim Nolan (from Madison) had just spent a week building the controller that will spend its life surveying the on-board power scene to determine how much free solar energy is available for the thruster at any moment (assuming no emergency override). He returned last week, fresh from the Embedded Systems Conference, and dove back in…

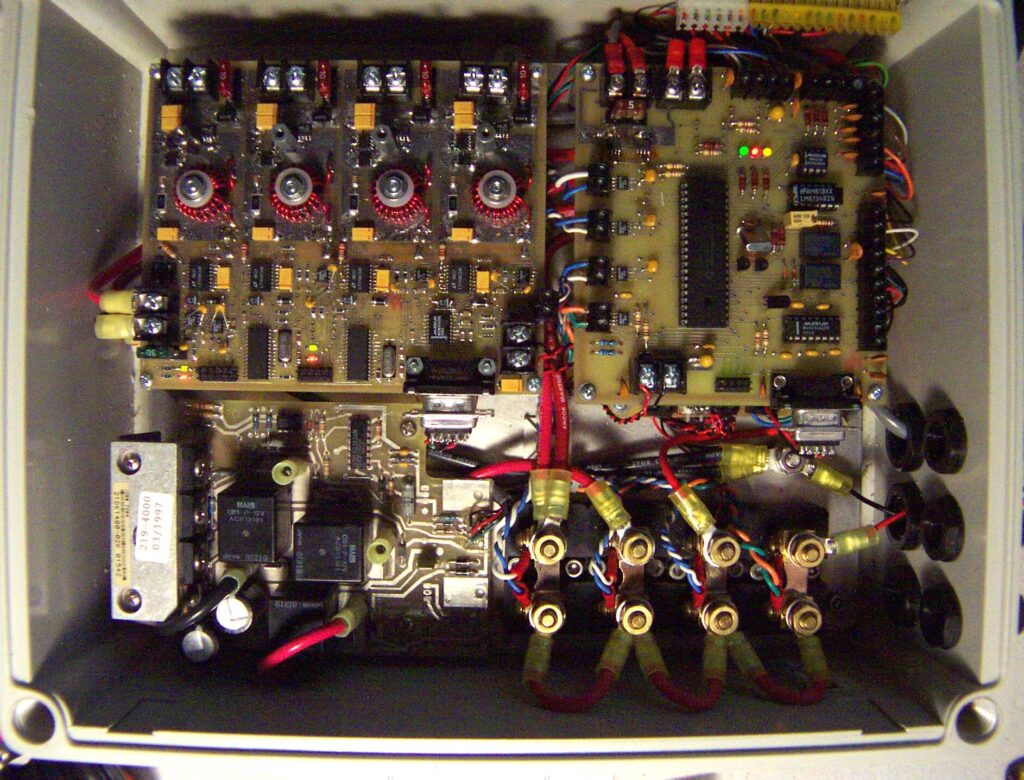

As before, he made astounding progress, nearly finishing the whole Microship power management system (Node P, photo at the top of this page). Five power-cycled Microswitch Hall-effect sensors allow current measurement of both halves of the solar array (about 16 amps each), the battery, the thruster, and the console-full of system loads. In addition, it measures array voltage on the input side of the battery and thruster controllers, allowing a simple peak-power tracking algorithm to continuously “twiddle the knob” to maximize the product of voltage and current. All this system data is inhaled through a 12-bit A-D converter on the New Micros 68HC11 board… which actively babysits the battery via an interrupt-driven PWM algorithm, rations thruster power via a hack to the Minn-Kota controller, and reports all the gory details to our front-end server.

After whipping all this out and getting it working, Tim had a couple of spare days… so he took on the next project: H-bridge control of the Minn-Kota steering motor. The thruster is deployed via this pivoting black box, into which indexes the heavy fiberglass tube that supports the motor itself and carries its power cables. The goal here was to allow manual or automatic control of thruster angle, calling, of course, for position feedback. Tim solved this neatly by gluing a couple of magnets into the nylon gear train of the steering assembly, using Hall-effect sensors to let the processor keep track of position and re-center the thrust angle if a crash ever knocks them out of synch.

We’re now shipping all the power components to him in Wisconsin for final refinement, transfer of circuits from proto-boards to perfboard, and algorithm-tweakage… whereupon it will all be ready to nail down in the console to establish the critical power infrastructure of the Microship.

Console Mockup

Yes, the console is getting close. Bob finished the cowling — a remarkably complex foam-core fiberglass part that is gasketed onto the boat’s gunwales, carries a Nicro powered vent and a slew of small antennas including GPS, loosely hinges for console access, provides a tiny nonskid step platform for going forward while underway, passes furling control and mainsheet lines, and withstands body weight at any point. Given real dimensional data, we were finally able to extract maximum console profile, then made a 2-D template by horizontally projecting shin and toe interference points while pedaling.

Then came the fun part. On a full-size Masonite substrate, I began precisely hot-gluing dozens of 3/4″ Masonite strips into a network of intersecting struts. Every frame member is the moral equivalent of aluminum angle, but not necessarily at 90 degrees… since all surfaces, inside and out, form gasketable frames for flat hinged panels. The dominant feature is a large opening, 29″ wide and 8.5″ tall, for the Lexan window that covers all the LCDs: linux server, Macintosh, nav PC, hub status LCD, the LED matrix, and a few tiny displays extracted from dedicated hardware.

The display panel is tilted slightly back to optimize visibility and height without allowing low-angle sun reflection into my eyes. On either side of the pedaling envelope, steeply-angled subconsoles carry standalone instruments, power and thruster controls, an unhacked GPS (do you trust a multilayered network of computers for basic navigation?), a compass (for that matter, do you even trust power?), and so on.

Mechanically, this is something of a nightmare, and we’re still trying to decide whether the final unit will be TIG-welded aluminum bar stock slathered with low-viscosity epoxy to fill the cracks, or built entirely of fiberglass and goo. It has to hold pressure, conform to a nastily complex shape, hinge around the leading edge to maximize access past the gunwale bellies, carry a massive sealed connector subpanel, allow EMI suppression, and be roomy enough inside to allow access to all mounted hardware. Should be amusing…

Landing Gear and Rudder

Speaking of amusing, Bob Stuart has been working on another underestimated project: the landing gear. Some time ago, we accepted the fact that full-time adventure on canoe-scale trimarans absolutely requires self-trailering capability — without a chase vehicle lumbering around the US, we’d be limited to dragging our 650-pound boats only partially up a beach like frustrated coelacanths or leaving them in the water at all times while trundling off to camp. None of those are particularly appealing, which explains the dearth of options between the portagable world of canoes/kayaks and the marina-centric world of yachts. In between, you find daysailers, which, by definition, depend on a trailer waiting in a parking lot next to the launch ramp… hardly suited to open-ended wandering.

Seitech Launching Dollies got us started in the right direction with the perfect wheels: readily replaceable tires on plastic hubs with Delrin needle bearings… the whole affair light and impervious to saltwater corrosion. But turning those into deployable landing gear is a HUGE project.

Bob has spent over a month engineering this — analyzing endless variations in suspension design, tuckaway retractability under the solar panels, deployed footprint, steering geometry, transient impact loads, bearings, materials choices, and uphaul/downhaul methods. He’s played with bungees, gas springs, and stacks of elastomer doughnuts; titanium, aluminum, and stainless struts; and countless variations in angular positioning to beat the wicked trade-offs of waterline interference, strength, suspension range, lateral stability, and nestling into the mothership for major cross-country jaunts. We sit and brainstorm methods of extending and retracting the damn things, ranging from hydraulic cylinders to a complex system of eight lines threaded through countless blocks and cleats… lately diverging into capstans and gearmotors with worm drive to automatically set up a triangulated tension-compression structure for each wheel upon demand. It’s all quite mad, but it will happen somehow. Stay tuned for the final details; in the meantime, we continue our quest for the unbeatable lightness of bearings…

The temporary rudder lashup used for the Port Townsend sail has been discarded and replaced by another of Bob’s works of art — a rudderhead that pivots on integrated pintles, supports uphaul and downhaul of the sleek carbon-fiber blade from Moore Sailboats, and allows control via two amazingly light hydraulic cylinders, each a closed loop to a sliding control grip in the cockpit that will ride on a Ronstan traveler car.

A lot went into this. The Fulmar-19 has simple and effective pivoting steering levers for each hand connected via the rudder and a cable looped around the forward bulkhead, but an even more natural motion is linear… which also gives us the chance to improve resolution by giving each hand a 6-inch travel. The use of two closed hydraulic systems, with the hands linked via the rudderhead, gives the system built-in redundancy and eliminates messy taut wire runs with rattling turnbuckles. We’ll put the traveler track and hydraulics under the deck with a stiff linkage to the grip itself, keeping the deck free for arm clearance and allowing lots of space for chord keyboard, pointing controls, system target buttons, push-to-talk, and possibly the throttle pot and direction/override switches.

Clippard Instrument Laboratory graciously donated the cylinders — actually designed as corrosion-resistant pneumatic units (stainless steel bodies and rods, with Delrin end caps). They added special seals for us, and we’ll use a light mineral oil as the working fluid.

We did a second test sail recently, with much less fanfare than the first one. This gave us a chance to test the new rudder (no hydraulics yet — I controlled it with a sort of homemade tiller extension, still a major improvement over the kluge bridle!). We launched at Camano Island State Park along with Cy’s Fulmar-19, with Lisa and Bob in the latter to tag along and snap some photos…

The 93 square foot WindRider sail — battened, roachy, and pulled taut with a boom — coupled with the slippery Wenonah canoe hull form that leaves almost no wake, blew the socks off the other boat! Lisa kept shouting for me to slow down so she could get some pictures, but I couldn’t seem to find the brake lever <wicked grin>. We also did a quick pedal-only race, and the Microship pulled ahead easily. We’ll have to do a performance comparison under balanced load and pilot conditions next time to be sure… but it was most encouraging to see this machine work so well!

By the way, in the photos you might notice she’s a bit down at the stern — this is before mounting the battery at the forward bulkhead and bolting on an electronics-laden console. We’re reasonably confident of good balance, and are using a custom weight-study database in FileMaker Pro to keep track of longitudinal and lateral centers of gravity (I’m trying to get it together to market this as a boatbuilder’s and cruising provisioner’s tool: anybody wanna get in the software-peddling loop? I’m useless at this sort of thing…)

MIMSY and the Linux Box

In parallel with all this, some exciting things are happening in the front-end design. As you may know, we’ve gone through a couple of major revisions already — first writing our graphic tools in HyperCard, then undertaking a huge project to build a server on the resident Mac with user control panels implemented as NewtonScript views. When Apple pulled the plug on Newton, we moaned in despair… but buried in there was a strong lesson in platform independence and the value of a large developer population.

It was but a short hop from that realization to the new system: a dedicated linux box atop the FORTH control network, serving pages to any browser that chooses to connect through the on-board Ethernet (including remote connections via the Internet). Suddenly, but for a few details, things get very simple… most of the hard work is already done and available off the shelf as continuously-upgraded web servers, browsers, Perl, Java, and other whizzy tools.

This is not to say that it’s trivial. Brian Willoughby has been working on the Microship daemon (with the characteristically unpronounceable unixish name, “ushipd”), whose job is to handle multiple threads of yakking between the FORTH system and whatever telnet session or web server happens to have business with it. So far, it’s just doing basic serial communications via a 4-port serial card donated by Joe Tyner — letting us Telnet from the Mac in my office to a New Micros FORTH 68HC11 board (which is pretty perverse, now that I think about it). But coming up Real Soon Now is added intelligence in the daemon that will maintain an image of all current system variables, keep an eye on watchdogs, restart crashed nodes, hand off telemetry snapshots to a scheduled mailer and database update daemon, and so on.

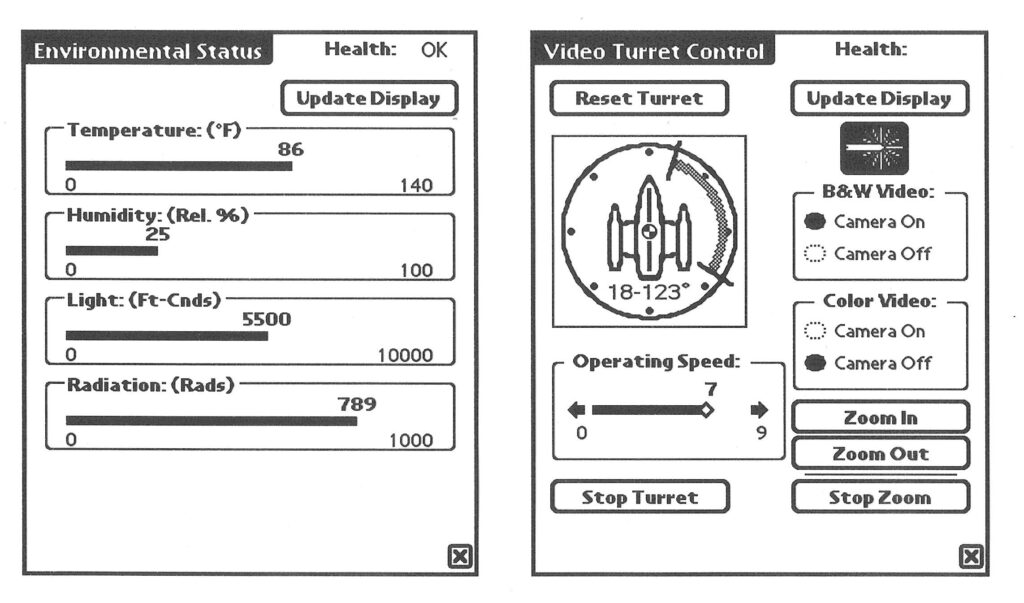

On top of that is MIMSY — the Microship Information Management SYstem. I’m having a ball with this: it’s the Microship’s on-board home page, the thing I’ll see from any local or wireless browser when I surf to the server’s IP address. (I suppose we’ll be doing a lot of pier-to-pier networking, and maybe even making a few slip connections.)

Anyway, MIMSY’s welcome screen is just a basic tool selection, which, in the current incarnation, looks like this:

- Interactive Microship Control

- Documentation

- Project Management

- Databases

- Microship.com clone

- Linux filesystem

- Net gateway

- Video monitors

- Navigation tools

- Toys

The first one is the most exciting, consisting of a layered set of windows into Microship operation. Power, for example, will appear as a “live” block diagram of the system, with active display of current parameters along with clickable switches and other controls, pop-up solar history windows, battery fuel gauge, and so on. Raw turret control, as with Chris Burmester’s inspired Newton design, will be a top view of the boat with a circle around it; click anywhere to aim the camera in that direction. And so on for macros, security setup, remote control, sideband control panel, raw crossbar setups, and the countless other widgets that map human desires onto a textual interface.

Most of my work on Mimsy so far has been in the Documentation section, which breaks down into the two domains of Microship details and general reference material. FORTH listings, schematics, text narratives, frequency lists, crossbar channel assignments, drill sizes, NAVTEX beacons, galvanic series… hundreds of individual files appear here in an easily browsable hierarchy.

And so on with the rest… a front-end to a database of time-stamped telemetry records, browsable mirrors of my personal databases, a complete copy of our public website including archives of stories, a symlink to the Linux root filesystem, and even a passel of javascript calculators snagged off the Net… the whole point is to bring the vast bulk of my information and control needs into a single familiar window.

In the present design the Linux box (maybe a hacked Libretto… or something from the embedded world such as ZF Micros’ teensy machine… or perhaps the amazing Xybernaut Mobile Assistant wearable we saw a few months ago) will have its own local small LCD, even though it could technically run headless. My preferred personal workspace is the Macintosh, where I’ll run MIMSY, write, do email, and so on. And I’m being dragged kicking and screaming into the Windows world for the third machine… read the excellent Captn Jack’s catalog of nautical software products (almost all for PCs), and you’ll find that the best central display for a ship full of integrated electronics is not an LCD radar with chart plotter option, but a PC laptop. In addition to a wide range of charting and navigation software, there is a radar display interface, the stunning PC/View scanning sonar from Interphase <swoon>, a TV receiver, weatherfax from various manufacturers, Icom’s stunning PCR1000 receiver, live satellite weather image receivers, tide/current displays, and much more.

So we’re up to three high-level systems, each optimized for one major applications area, all networked via Ethernet and usable simultaneously via the BAT chord keyboard and Interlink pointing device on the rudder control (with the aid of “target” buttons to specify which machine is being controlled). It’s not just a canoe anymore… and Canoe’s not Unix!

One final note… we’re seeking a hand-me-down Pentium desktop PC with a gig or so of disk and a CDROM drive to serve as our linux development system… anyone have yesteryear’s slow machine to donate or loan to the project? We also need a router… at the moment, we have to reconfigure the TCP/IP settings to switch between PPP connections via local modems and the lab ethernet by which we talk to the linux box. Seems all that should be integrated somehow…

Random News and an Invitation

Well, as you can see, a lot has been going on! In other news…

If you’re in the Puget Sound area, are a confirmed technogeek, happen to be free this weekend (Nov 21-22), and haven’t already heard from me, please email me immediately! There’s a Northwest Geekfest and labwarming afoot…

Many thanks go to a few volunteers: Rich Muttkowski has been a true hero here, dropping by most weekends to work on various building projects. Paul Elkins, who has built a number of amusing tiny boats of his own and knows a lot about bending tubing, has given us a hand with sanding and chainsaw sharpening. And a technomad named Casey, passing through on a recumbent, stayed a few days and did a bit of abrasives engineering himself.

Bill Vodall WA7NWP, whose name appears frequently in these updates, got the lab APRS station running (Thanks to Bob Bruninga WB4APR for the APRSdos program, and to Keith Sproul WU2Z for MacAPRS). We dedicated my HP Omnibook 430 along with a Yaesu 290 and a PacComm Micropower-2 TNC to the DOS version, and it’s sitting over there now displaying a vector map of the Seattle area with a couple hundred ham stations overlaid on the screen. Interesting stuff…

In the media department, we just did an interview with the Stanwood/Camano News, and I found an online video clip (as well as story with pictures) of our New Media News interview.

And finally, believe it or not, we actually have current information about the Microship project on our website! Lisa worked hard on this (once I finally delivered some text) and did some lovely graphics, though she’s still shy about putting her own cute mug online. Nevertheless, if you want a cogent summary of the whole project, complete with a map of the projected route, sexy graphic timeline, work-in-progress photos, an annotated drawing of the boat by my sweetie, and a block diagram of the control network, get thee to <old link redacted>.

I’m off to work on a Dr. Dobbs Journal story about the crossbar networks… then back to hot-gluing masonite!

You must be logged in to post a comment.