The Zen of Geeky Boat Projects

The beautiful photo above shows Sky at the helm of Nomadness.

I’m anchored north of Hope Island at the moment, the boat feeling much lighter off the dock, the rhythm of life distinctly more relaxed than the task-oriented staccato that has characterized the past eight months. There is much of the latter yet ahead, alas, but this break is a good reminder of why I’m putting myself through this.

As expeditions go, this is a minor one. There was talk of popping over to the San Juans, but my diesel is suddenly putting out black smoke above 1800 RPM or so and I have yet to diagnose the problem. (That typically means partially burned fuel from either restricted airflow, high engine load like a fouled prop, exhaust back pressure, or a bad injector.) I’ll deal with it, but for now I am more focused on remembering life aboard… the best part of which is the pace.

At the lab, I juggle management tools, nudging a dozen parallel projects ranging from eBay and homeowner stuff to enclosure fabrication and boat network design. It is never simple, never feels calm, and only rarely gives any indication that it might end someday.

But now I’m swinging at anchor, a pasta in the oven, Sky off to give the dog a shore excursion, genset purring to slurp a few amp-hours back into the aging AGM bank, body pleasantly tired from unfamiliar exertions, a hint of sun-sting here and there, and really nothing I urgently need to do at the moment but write this blog posting. What a difference. One project can be the focus of a whole day, with time for a nap, a hike, a frolicsome dinkabout, and an eventful ride (complete with retrieval of a powerboat-pooped dinghy) over to Cornet Bay for ice cream with friends aboard Nereid… our buddy-boat companions on this little jaunt.

Projects aboard have more immediacy than the ones that involve Linux servers, distributed Arduini, and radio gear. Yesterday an intermittent in the engine-starting circuit blossomed into a full-blown failure, so I dug into the wiring harness, found a mashed-together butt splice that had not been properly crimped, fixed it, and vroom. It’s no big deal, but there’s a perverse, almost pleasant purity in having a single task in focus… and a real satisfaction in getting it done.

Especially when the engine starts again.

Random Thoughts on Boat Projects

This calls to mind a discussion that percolated on Cruisersforum recently… someone launched a thread on refit lessons and I was inspired to contribute. Given the focus of this blog, an edited version is worth including here:

- Never hire a guy who hates his work… I’m still fixing messes left by the plumber-from-hell, and there were lots of clues while he was on the job that should have been grounds for termination. The latest discovery: instead of using the correct bolts for the SeaLand inspection plate, he just shot in some sheet-metal screws. This distorted the polyethylene Ronco tank material, with one screw even penetrating the sidewall of the oversize cutout… creating a gap that leaks under pressure and insufficient material for a proper re-installation. This hotshot charges $80/hour. Hiring First Mate Marine was a mistake, even though some of the tasks were intimidating and I felt I needed his skills… but ever since, I have been chasing leaks and cleaning up after him.

- In that spirit, I’ve learned that DIY should always be first choice, with the hiring of professionals limited to cases of esoteric knowledge, true gurus, or jobs requiring expensive capital equipment. As I proceed with the geeking-out of the ship, my “business model,” although very casual, is publishing the designs and in some cases assembling kits. I think a lot of boaters are coming to the same conclusion, and the economy has a lot to do with it.

- To-Do lists are fractal. The closer you zoom into one item, the more it expands into a cluster of component items. I try to anticipate this with what I call “CDTs,” or Clearly Defined Tasks. Writing these out ahead of time may seem like over-detailing, but pays off when it helps avoid gross underestimation of time and costs.

- Project management tools can make or break a job. I like OmniFocus since you can list by projects and then review by contexts (like, “what else do I need to do now that I’m aboard with wiring tools spread out?”). And Scrivener is very useful for keeping the sprawling collection of design documents in one cohesive environment… before that, I had stray files everywhere.

- If a project requires n components, there will be n-1 units in stock (quoting an ancient collection of Murphy’s laws, circa 1969). It is really worthwhile to buy in bulk… and besides, you end up with repair inventory and trade goods. For hardware, McMaster-Carr is spectacular.

- Tool duplication between home and boat is unavoidable. You’ll end up needing ’em anyway. Expensive tools are usually good investments, though they sink just as fast as cheap ones (don’t be too macho to use a lanyard when leaning over the rail). The new Li-Ion Makita LXT power tools are awesome… I love them, along with the best drill bits I’ve ever owned. This felt like a crazy splurge at the time, but has already been a winning investment.

- Document, document, document! Buy a cable-labeling machine and ID every cable as it is identified. Take the time to do good drawings (I use OmniGraffle Pro for overall diagrams, and Eagle for detailed schematics). Start a binder for the known-correct information that you will want to be able to find again… sprinkled throughout project notebooks and random scraps, it gets lost. Dedicate portable file boxes to manuals and individual projects. Use your digital camera to chase otherwise invisible mysteries, and save the images. Take photos before closing off an area so you will know later where not to drill.

- Save labeled core samples from hole-saw adventures.

There are a lot more lessons that fall out of all this, and I’ll share them as they occur. But for now, there’s a bit of catch-up to do; somehow I let 5 weeks get away since my last posting here.

Stove Cage

The Navigator Little Cod wood stove that was installed last year was excellent company over the winter, but one job remained unfinished. The exposed stovepipe, especially with the related sacrifice of a wooden pole in the cabin, was an accident waiting to happen: hot or not, a lurch into sharp sheet metal during a hands-free transit at the instant of wave impact could have devastating consequences. So I built a cage:

I’ll probably soften up the top rail and the upper halves of the verticals with St. Mary’s hitching some night at anchor, but even as it is we already find it pleasant to use as both a leaning station and a grabrail when passing through. The parts are standard 7/8″ rail and associated fittings, and the 60° angle of the struts both opens more rail to gripping and minimizes flexion of the top half.

Curtains

Another major lifestyle enhancement in the raised-salon pilothouse is a set of curtains… especially on the sloping front windows that make a highly effective greenhouse on sunny days. After months of frequent staring at the problem and a number of brainstorming sessions, we decided to take a novel approach and use high-power neodymium magnets sewn into the edges of the curtain panels… with matching ones attached to the window frame with double-stick foam tape. Our fabrics guru was not at all happy about trying to keep feisty magnets under control while sewing on her industrial steel machine, but eventually she got them all in there.

The panels are a lush patterned dark blue fabric inside, and a special light-colored UV-resistant material outside. And while there is a little gaposis and sag, they are a huge improvement in quality of life aboard. Peeking out is easy: just pop open a corner, have a look, and slap it shut. It is much tidier than rods and associated hardware.

(The black contraption at the top wrapped in foam and gorilla tape needs to come out – it’s one of the old windshield-wiper motors. I’d like some, actually, but one of the three melted its wiring in the harness and I no longer trust them… and besides, they are head-bangers. One of these days.)

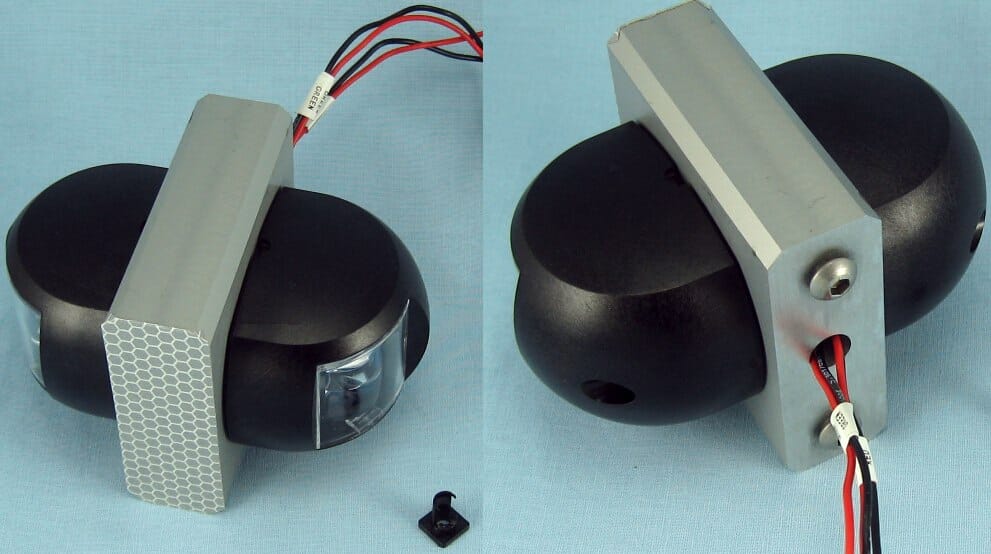

Bow Navlight Assembly

In my last post, I moaned about the mounting scheme used by the Aqua Signal Series 32 LED navigation lights, and I remain unimpressed… it should not have taken so much work to get them installed. One of the units, fresh from the clamshell packaging, had the key expando-plastic toy part fractured and useless, so any cop-out attempt to mount according to the nearly nonexistent documentation was out the window anyway.

Instead, I cobbled up a little machined aluminum assembly that bolts to the original mounting plate that carried a milky incandescent power-hog from yesteryear:

(That little black thing in the foreground is the broken critical mounting part, which is supposed to expand when a tapered knurled brass plug is pulled into it by the one and only mounting screw. I like my approach better… a longer #8 button-head, turned down slightly to fit in the metric-sized hole in the plastic, threaded into a block of aluminum. This might have to take green water over the bow someday.)

Marine GPS Datalogger Kit

Thought I’d insert a quick plug for our little datalogger; my enthusiastic tales about various incarnations of this technology have generated a lot of interest over the years, so I finally packaged my favorite logging engine along with a sealed enclosure, charge cable, SD card, mounting velcro, and expanded how-to. These things are a hoot, and provide all sorts of graphic evidence of adventures (and embarrassing oops moments like trying to dock in a cross-current). The marine GPS datalogger can live permanently in some out-of-the-way location with a sky view, and is accessible via Bluetooth. Over 6 months of continuous track logs (one point per second) can accumulate in the SD card before it starts to get crowded in there, and the retrieved files can be displayed in Google Earth, Google Maps, or other formats with a free online tool.

Nomadness at Anchor, Part 2

This posting has been idle for a while, though I have occasionally poked at it with a stick or added notes about stuff to add. I should just do short postings and not make each one such a multi-threaded repository of techno-philosophical musings. Old habits die hard; I still think of these as articles and use my vintage live page for short news bits of interest to friends.

Anyway, I’m at anchor again. A week or so has passed, and the big week-long regatta has taken over the marina where Nomadness has been moored. Us riffraff have been asked to vacate the docks to make room for all the go-fast toys, so for a while we will be gunkholing about, taking friends for long-promised sails, and returning randomly to the lab to keep the nickel generators sputtering along.

It has been a very eventful few days. Way back at the beginning of this post, I mentioned the black smoke above 1800 RPM. This was quite worrying, and I concocted a theory that the diver who replaced the nose zinc on my Max Prop had somehow fungled the pitch and increased engine loading. Only… it still went from forward to reverse so was not jammed, and an email exchange with helpful PYI tech support pretty well convinced me that such a phenomenon was not possible. I have the Classic 3-Blade model, shown here during the pre-purchase haulout before cleaning and zincage:

I was not happily contemplating either an engine service call or haulout with prop-removal… so, grasping at straws, I asked the diver to take a look even though it has only been a couple of months since the last cleaning. And guess what… this has been the worst year in memory for marine growth around here! It was fouled from bow to stern, the running gear covered with barnacles and other biology. They went back down the next day and polished her up, and yesterday I cranked the engine to 3200 RPM and purred along smoothly with nary a wisp of smoke. All betterz…

Feeling smug about a cheap solution to a scary problem immediately induced another one… I carelessly let the furling line get away when deploying the headsail, so at the end of the day, rounding up in a fresh breeze to anchor off a friend’s beach, the sail got stuck HARD when still about 30% out. No amount of fiddling had any effect, so I cast off the furling line, wrestled the drum around until I had a couple of sheet wraps, and tied it off to the pulpit with small stuff. All day today, with gorgeous perfect breezes and sails dancing in bright sunshine, we swung at anchor waiting for enough calm to drop the basket and untangle the mess.

I suppose there are worse things than a day at anchor since we had no place in particular to go. “Cruising,” quoth some ancient wag, “is the art of fixing your boat in exotic ports.”

A Critical Comment

This is a good time to answer a comment from “Anonymous” that came in response to my blog post of a few weeks ago. Every now and then, someone will write a stinging criticism of my peculiar blend of passions, usually from the perspective of the traditional values associated with the most visible substrate. Someone in 1989 told me that I was “bastardizing the simple, beautiful act of bicycling” with the BEHEMOTH project, and a few years later, a guy in Arizona lambasted my transition to the Microship… insisting that I remove him from my mailing list since I was “abandoning my bicycle roots.” One needs a bit of a thick skin when making a life public, and I was initially going to just ignore Mr. Anonymous. But he actually makes a valid point that I should address, even though he did not do so very kindly:

So mr nomad how’s outfitting the space shuttle going? Excuse me for being skeptical, only you seem stuck in the yuppie yesteryear of “too much is never enough.” Complex systems galore, oh…and you’re going to swing it by going global and what… tweeting from fiji?

Salt water, the motion of the ocean, an unrealistically long supply chain combined a global depression will have the final word on your work I feel.

Really, go cruising and report how the multitude of systems are holding up… that is if you aren’t too busy maintaining broken systems. I’ll give your techno path some credence if you can go a year or two of cruising without giving up in exhaustion.

There are a few things this fellow is overlooking, though his perspective on complexity is not uncommon in the cruising community and is not entirely irrational.

First, and I think most of my readers know this, my primary source of geek pleasure is the blending of passions. From my ancient 1983 “computerized recumbent bicycle” to this crazy starship-to-be, what has kept me going for a quarter-century has been the integration of geek delights into adventure substrates and then (usually) spending quality time playing with the quirky combination. So my initial response to his comment is that I am not just getting distracted by technology in what is fundamentally a cruising project; the whole point here is the combination of the two.

Of course, he is absolutely correct in pointing out the potential fragility. Water corrodes; salt water corrodes absolutely. Systems crash, parts can be hard to get, and complexity is anathema to reliability. A purist would have already snorted at my furling drum problem; a hanked-on jib would never “jam.” And if I do find myself dealing with constant electronics failures, then I have not done my job well, since a rather large percentage of the design is related to robustness, sealing, serviceability, isolation, backups, and easy replacement if it’s all toasted by lightning.

But beyond all that, one of the fundamental design standards here is that none of this gizmology can be mission critical… at least in the sense of disabling basic ship operation if it fails (like requiring power to move a swing keel on a high-performance race boat). I still pull strings for sheets and halyards, there are TWO independent hydraulic backups to the autopilot as well as a wind vane and emergency tiller, I have an Astra IIIB sextant on board that will still work when the GPS toys crap out, I don’t use microprocessors to control navigation lights, and safety-critical things like the marine VHF are not dependent on crossbar networks to get audio in and out.

So why, one might cynically ask, am I farting around for years with lab-logistics and development tools when I could just go cruising (other than the fact that I find the geek stuff fundamentally entertaining)?

In a purely practical sense, the systems that I am building address a very specific need that is not well met by existing tools. When I am off the boat, I want to be able to see it and scan sensors. When I am in bed and it gets bouncy, I want to reach up to a display and take a quick reassuring look at GPS guard zone, depth, and wind data. When batteries are sagging, I want to know why. When I forget how the 20 or so valves related to engine fluids are configured (3 tanks, 2 Racors, transfer pump, oil changing system, coolant loop pickoff for water heating), I want to see a live drawing with active lines a different color than inactive ones and relevant flow sensor values displayed in context. When I’m tired and try to fire up the macerator pumpout without first opening the tank vent and seacock (duh), I want something to yell at me very loudly. And so on.

None of this suggests that I should get lazy and hand all responsibility over to systems; instead it is an attempt to bring the insane complexity of a modern cruising yacht’s systems into a user interface that looks and feels like a simple website… accessible from anywhere on or off the boat. If that fails, oh well. The boat still works.

A secondary benefit of all this, besides my finding it intrinsically fun and justifiable on that basis, is that a lot of other people are interested as well… so there is an associated business model that yields publications and kits.

Finally, a bit of broader perspective… sailing itself is not low-tech, even though it has been done for centuries. We’ve come a long way from square-riggers and tallow-tipped sounding leads; by the time you throw in N2K navigation networks, watermakers, high-brightness LEDs, windvane self-steering, carbon composites, FLIR, forward-looking sonar, broadband radar, and MPPT solar charge management, a cruising boat is a masterpiece of multi-disciplinary engineering. But I think I understand Mr. Anonymous’ objection to complexity: it is anything that is not already a turn-key product.

Footnote: Life Under a Lightning Rod

I was just about to send this via the trusty EVDO link when I started seeing flashes outside, and emerged to observe huge cloud-to-cloud lightning displays covering many miles (with occasional ground strikes). When you’re in a steel box with a 60-foot aluminum stick in the air, the tallest thing around with a hook down just off a lee shore as reversing wind gusts whistle the rigging, this is somewhat disconcerting.

The dilemma: stay aboard, let more chain out, and watch the sky show… even though swinging then becomes dicey if the wind shifts to the west… or hop in the dink and paddle to the home of an out-of-town friend. We opted for the latter, and have been watching my anchor light drift back and forth like a motile Venus against a backdrop of lightning-streaked clouds and distant shoreline.

A nice, primal footnote to all those existential questions about the essence of technomadics…

Fair winds,

Steve

On "A Critical Comment"…

You are absolutely right Steve. We get the same sort of comments about our use of geeky toys/electronics on board (we probably have the most you can pack into a 28 foot monohull sailboat).

For us mastering these devices IS the challenge for our kind of "cruising". Its a FUN challenge. That is not saying that we soley RELY on these devices. We do have paper charts (my wife insists) and sometimes bring the sextant for sight practicing.

In fact our most recent cruise saw our charging system fail and we had to turn off all geek toys to conserve battery for a couple days. We had no worries navigating the "olde way", using paper charts, tide books, motoring though currents at night. In fact is was refreshing.

Sometimes those hardnosed purists are just too… well… hardnosed.

Steve, regarding Mr Anonymous {rolleyes}, it's quite obvious that he doesn't know who you are or what you've done in the past. It's hard for some people to understand how a geek thinks. They just doesn't "get it," and I don't think there's any way to make them understand, no matter how you try to explain it.

If systems fail, as he predicts (and no doubt something will at some point), then you learn from that and redesign it better. And that is fun. To him, tinkering with complex electronics is a hassle, and a distraction. To a geek, it's enjoyable, and something that enhances life.

I remember a few years ago when you started looking at bigger boats, you wrote that you didn't want your website to become just another unremarkable blog by a guy cruising around in a yacht, of which there are plenty. You've certainly avoided that, but Mr. Anonymous is suggesting you do exactly the thing you were trying to avoid.

In addition, as you mentioned, the potential exists to generate some dimes and nickels with it all. People are interested in what you are doing.

In any case, you really shouldn't have to explain yourself.

– Eric

Steve …. just thought I would leave a comment from England …. not at anchor just tied to the tow path …. I read the blog from time to time to feel salty again but have begin to settle in to the life on the canal …. still alive here now with a long term visa so we don't have to leave every 6 months …. house in AZ is still for sale but what the hell this is fun ….. Frank Sharp

Frank – wonderful to hear from you after all these years! Please email me; I'd love to catch up in more detail.

RJ and ER – thanks so much for the supportive comments! Highly appreciated….

(sorry about the duplicated comment from RJ – blogger got confused and presented it twice for moderation. I didn't want to risk losing it, so accepted it a second time.)

Nice post. I don't believe we need justify our passions or what turns us on. That it does (turn your crank) is all that matters.

So sail and tinker on, you beautiful geek. 🙂

p.s.: Khalan says you're on Facebook? Come find me — I'm listed under Anne Marie (no last name).