Fabrication Home Stretch

Above: Microship website in early 2000

by Steven K. Roberts

Microship Status Report #135

April 11, 2000

“Once you can accept the universe as matter expanding into nothing that is something, wearing stripes with plaid comes easy.”

— Albert Einstein

PSST… Hey, Wanna See the Microship?

Ahhh, Springtime. A young man’s fancy turns to boats, road trips, and high-speed network access. In the foreground is a To-Do list that’s becoming ever more tightly compressed into the 7 weeks between now and the PerlWhirl; progress is happening, but the distractions of project management keep drawing me away from project execution.

Still, we do what we gotta do. At the moment, that translates into a putting together a speaking tour this coming August… with a keynote scheduled in Asheville, North Carolina on the 16th and a few visits in between. This is the opportunity I’ve been waiting for: we’re hoping to land enough gigs on either side of that date to justify purchase of a new Wells Cargo 48-foot trailer to replace my wee 20-footer… which in turn means we can take the Microships cross country as well as the bike! If this audacious plan comes together, it will be the first speaking tour with the boat… and very likely the last with BEHEMOTH before it lands in the museum.

Soooo, if you are involved with a company, school, event, or organization that would like to host an on-site appearance… please let me know right away! At the moment, just about anywhere in North America is fair game, though as our travel schedule develops, the constraints will grow tighter. The general plan is to head east at the end of July to appear at the SolWest Energy Fair in John Day, Oregon, then pass through St. Paul and Madison, aiming ourselves toward North Carolina before reversing course, visiting my dad in Louisville, and cruising west to Silicon Valley (maybe via San Diego) with a few sailing days tucked in here and there. But there’s lots of flexibility in that, including the other two corners of the US. If you’d like more info about my presentations, appearance fees, and how all this fits with various kinds of audiences, please drop me a line and I’ll see if we can work something out.

Ooohhh, a 48-foot Mothership….

Microship Labcam… NOT

Until this afternoon, we had a labcam serving hourly images to our website… but the recommissioned Quadra stopped believing that its disk can be read by its operating system version! I’ll dust off an old laptop and try again — hopefully this will be back up soon… it’s quite amusing, but at the moment the image is static.

In other website news, Natasha is in the process of doing a complete redesign. We’re planning to have it online by May 15, which is when the June Wired article should hit the stands. In addition to all-new aesthetics and structure, a Perl script by Ned Konz serves a random sponsor logo every time the front page is accessed, archives are easier to find, there are more pictures, the Microship overview has been rewritten to reflect the current system design… and the tools are falling into place to support the virtual console and Steve Dimse’s magic tracker display. (I’ll carry the APRS tracker on the upcoming test sail, so you will be able to see real-time location data and power system telemetry.)

Elsewhere in the Yachting Spectrum

We actually had a bit of Time On Water last month… a 2-day delivery cruise aboard a friend’s Morgan 41 Out Island from a boatyard along Hylebos Arm (near Tacoma) to Whidbey Island. Actually, Tasha and I jumped ship and dinghied to a Camano Island beach as I had a meeting to attend, but that was just part of the adventure.

Jessica, the owner of the boat, had ‘er shipped up from Mexico, so the first task was to re-rig and get the systems back online after thousands of miles of road vibration. A rigger and crane showed up to step the mast (This is a stickup!), so all us swabbies grabbed a shroud or a stay, with turnbuckles and pins at the ready and wrenches in our teeth. But something went awry… we got the stick in and had the backstay and one shroud attached, but the headstay was suddenly a couple inches out. Odd… it looked OK a moment ago. I popped off the backstay turnbuckle and they got the headstay in with no trouble, but then I didn’t have enough slack at the stern. It turned out the tide was ebbing so fast that the boat was literally dropping out from under the mast, which was still hanging on its crane!

That problem solved, the six of us wired, fixed, cleaned, mounted, stowed, and otherwise got her ready for sea. We motored north the next day, giving me a chance to practice navigation in unfamiliar waters, cruising up the west side of Vashon Island as night fell… past the amazing lightshow of Seattle… dodging nuns while trying to sort out the visual clutter of lights marking Bainbridge Island’s Eagle Harbor entrance with its interesting shoals. Entering an unfamiliar channel in the dark is always a blend of white knuckles and enchantment, and this was no exception… but we found ourselves at last tied to a guest dock at the Yacht Club, exhausted but giddy, swaggering in our foulies up to the pub in salty camaraderie.

The other oddity of the trip took place the next day, after a lovely wing ‘n wing run up Admiralty Inlet as I watched my pocket GPS with increasing anxiety (the antithesis of proper sailing attitude, I know, but I was fretting about my meeting). The wind faded and we fired up the diesel, and at Jessica’s preferred 2100 RPM maintained a steady 6+ knot speed over water — just enough to make it in time. But after a couple of hours, I kept fretting that something didn’t feel right, and sure enough… the knotmeter read 4.6. “Faster!” I urged, but Jessica was adamant about maintaining 2100 RPM. Harumph… the speed log should be independent of current and there was no wind to speak of, so I set off on a walk around the boat to locate and free the forest of kelp that we were obviously towing.

But it was far weirder than that: a waterlogged 6-foot 2×8 plank was perfectly balanced across the bow, churning up a wave! We were trying to plow Puget Sound….

Physical Fabrication – Home Stretch

In Issue #133, I reported that we were in the process of prepping the aluminum parts for anodizing at Hytek Finishes, a project that involved disassembly of 170 machined components followed by sanding, polishing, and bead-blasting of each. The landing gear, in particular, required careful record-keeping — with a total of 324 parts (including fasteners and suspension blobs), I didn’t want to end up with a confusing mess months later after forgetting how it all works. Disassembly was thus documented with metal engraving, sketches, notes, video, and photos… while I became ever more amazed at the engineering challenge that was successfully met by Bob Stuart while building these crazy things. It seems that adding saltwater-impervious hydraulically steered retractable landing gear to a canoe is not a trivial problem after all… especially with Ackerman geometry, remote deployment, tuckaway stowage, and independent suspension that can handle 4G shock loads!

(Speaking of canoes, a friend recently pointed out that if Lewis and Clark had carried duct tape, it would have knocked a year and a half off their journey.)

Hytek did a beautiful job, passing our batch of Microship parts through the same processes used by Boeing and other deep-pockets clients who insist on serious quality control and batch uniformity. The pre-etch and anodizing steps were followed by a dichromate seal to survive the brutal marine environment, giving the parts a hard green finish that’s incredibly functional in appearance… just like aircraft parts. To add visual balance, I’ve decided to abandon the original drab “Pearl Grey” hull color and go with “Lemon Mist,” which is also compatible with blue Solarex panels and the red Sunbrella fabric of the cabin top. Io should look right festive out there… especially with lavender Europa rollicking alongside.

The big project at the moment is doing everything that has to occur before painting, which translates into a massive collection of hardware mounting jobs — Globalstar satellite antenna, four whips, GPS antenna, Mobri radar reflector integrated with sternlight, Guest spotlight and Az-El camera platform, speakers and cable channels in the arch, Delta anchor with rollers and tensioner, detachable cowling-hinge and draw-latch retrofit so we can get at the console, and so on. We’re also nearing the Solar Integration Project, as Bob is now vacuum-bagging the substrates on Saltspring Island and at some point we must bond on the mounting fixtures and connector nacelles.

In addition to the solar panels, quite a bit of other development work is taking place offsite. In Madison, Tim Nolan is refining the Peak Power Tracker boards that will let us extract maximal juice from the solar array — he’s seeing consistent gain in the 15% range. He’s also doing final tweaks to the main power control board, which gathers data from the solar arrays, battery, thruster, and system loads in order to optimize battery charging while delivering the magic number to the thruster controller that lets it track available leftover power without impacting the battery. Blue Sea Systems just sent a wonderful care package of shunts, circuit breakers, bus bars, fuse blocks, and other goodies that will take care of the whole power environment. (Tim has changed to high-side current measurement with Blue Sea meter shunts instead of the Hall-effect sensors we started with; while the latter work fine, they are fragile, draw significant operating current that necessitates power-cycling with attention to settling time.)

Meanwhile, the physical mounting problems alluded to a moment ago forced me to think about the whole communication system, since antennas occupy deck space, interact in interesting ways, have biological exposure effects that must be considered, and in some cases even require a counterpoise. I’ve been distributing the various whips to accommodate all the trade-offs and water/land modalities, but nothing was as messy as HF… especially since it has to work in salt, fresh, and NO water. With brilliant email brainstorming partners Ralph Wallio (W0RPK) in Iowa and Courtney Duncan (N5BF) at NASA’s Jet Propulsion Labs, plus occasional input from Roy Lewallen (W7EL), the author of EZNEC antenna modeling software, we have been going back and forth for a couple of months refining the design while reluctantly rejecting the convenient solutions one by one.

Basically, it appears that there will be a 102-inch stainless whip at the stern, pushing against as much bonded copper foil as I can possibly laminate below waterline in the aft hatch. In between, an automatic antenna tuner will busy itself with matching, recalibrating when we move from salt to fresh water or operate on land with an added ground wire. None of this would have been very difficult if we didn’t need automatic operation, as there are some excellent antennas that eliminate the need for a tuner (most notably the Outbacker, which served me so well on BEHEMOTH). But if manual intervention is required to change bands, we lose the ability to perform server-initiated telemetry via PACTOR and APRS when the system might have been left tuned for a 10-meter ragchew. All the numbers suggest that this approach will work, so at the moment I just have to worry about its impact on fiberglass… with the hope that our eagerly awaited Icom 706mkIIG will find itself in a happy RF environment when we at last put to sea.

I should mention that while all this is going on, Natasha continues to make amazing progress on her boat — working solo much of the time yet turning out some great layups. She has just contracted local wizard sculptor/welder Rick Wesley to conjure her landing gear, and is looking for volunteers who want to camp here for a while and help with electronics, machining, and other packaging projects. Our goal is to have Europa day-sailable by the time we do the August tour, so we can take both boats with us to sample some of the waters that we’ll be traveling for real next year. In the middle of being a boat builder, small-time chicken rancher and gardener, video producer, webmistress, and endlessly interesting companion, she also stretched her electronic wings last week by building the Paia theremin kit… with the intent not only of making eerie music but also building a gestural interface to the video crossbar to speed editing.

On the Systems Front…

Speaking of volunteers, we made a key decision that should have sweeping effects on the way Microship software comes together. As you may recall, Ned Konz lived with us for a while and made incredible progress in specifying the various modules that will collectively present a consistent interface to the suite of asynchronous and differently flavored data sources, with clients ranging from real-time Java charting widgets inside the browser environment to telemetry tasks that periodically gather everything interesting and ship it off to our public server. All this is wrapped around a database, presumably SQL-ish, and Unix-domain sockets take care of the interconnection between device servers and the central switcher that routes channels to various clients. Most of this data flows in via the serial crossbar or through the original FORTH hub system, which is now an I/O manager that greatly expands the Octagon board’s already substantial set of ports.

Given the linux development environment and the remarkable culture of our age, we’ve decided to put all this under GNU Public License… in other words, open-source. We’re setting up the project website, mailing list, discussion forum, and CVS (version control) tree on Sourceforge, and are now actively seeking other team members in addition to the half-dozen who have been involved so far. If you want to look over the spec, please go to our development homepage at Sourceforge; if you’re interested in getting involved, let me know!

You know, it’s funny… as this develops I can’t help but reminisce about the project’s beginnings (maybe munging archive files for Natasha’s web project had something to do with it… I’ve posted 1.4 megabytes of textual updates in this series since 1993, enough for a substantial book). I never would have believed back then that we’d be writing real-time code in an on-board Unix-based wireless network environment distributed over two canoes and two backpacks, scattering tens of gigabytes of disk around and maintaining parallel satellite and HF telemetry pipes to a public server. Sheesh. We gotta get out of here and start traveling…

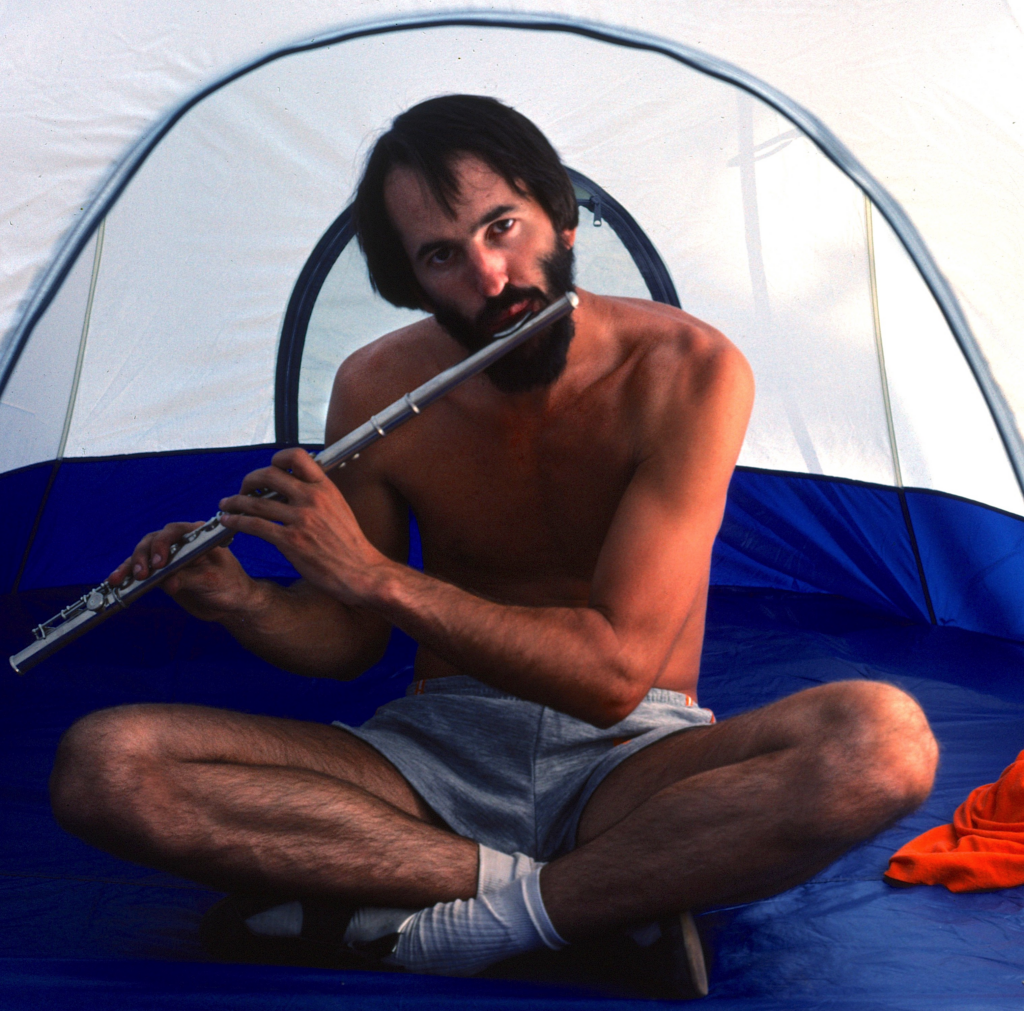

One of the applications I’m finding amusing these days is music — Tasha bought me a new Gemeinhardt flute and I’ve been jamming with friends, and I just Ebayed my old Casio synthesizer and bought a Korg X5DR. Even though I’m still a synth newbie, mostly just downloading and playing General MIDI files, it absolutely astounds me how good this little box sounds, how easy it is to view it as an accompanist, and how far a gigabyte goes when you’re storing MIDI data instead of the shape of every waveform, MP3’d or not. This will live on the serial crossbar, of course, just as accessible to system software as any other resource. The only problem is that it makes me care even more about speaker quality, and in the tiny cockpit I’m severely constrained by magnetic fields that affect the hand-bearing compass… EVERYTHING on a small boat interacts with everything else. Looks like the little 4″ ultra low magnetic field Poly Planars instead of the hearty Sonys…

News Updates

First, the sponsor news… it’s been over 2 months since our last update and we have some exciting acknowledgments…

I mentioned Blue Sea Systems earlier — I have long admired their marine power hardware and even used a bit of it when rewiring Rick Waldbart’s Sea Pearl in Tampa a few years back. Waterproof circuit breakers, robust bus bars, main fuse block, shunts, keyed main switch, and more… we now have enough on hand to take care of all our power wiring.

Some time ago, I reluctantly agreed to let Natasha build a structure on Europa’s arch to carry the video turret, the sealed 8″ cylinder containing a camera head with 450 degrees of rotation and an embedded FORTH board running PWM motor-control code. As much as I love this unit, she appealed to my vanity (or so goes the local myth), pointing out that I will be the subject of the video far more often if please, oh, please, she can mount it on HER boat . There’s some logic to this, as she’s also carrying the Draco Casablanca video editing system, but a lot of loving work went into that sparkling little robotic widget and I’m attached to it. But hey, lately I’ve been thinking that having elevation control would be even cooler, and while we’re at it, why not on-board IR illumination? This led naturally to the search for a suitable Az-El remote-controlled device that can handle the marine environment… and surprise… it already exists in a very useful form.

Thanks thus go to Guest (which is now an affiliate of Marinco) for their 100,000 candlepower 50-watt remote halogen spotlight! We’ll add position feedback like the scheme Tim retrofitted to the Minn-Kota steering motor, then stack on a couple of waterproof cameras from Supercircuits (one B&W with 104 infrared LEDs, the other color) along with a Coherent 15mW diode laser in a third sealed housing. The resulting Roving Eye module will be a remote-controlled see-in-the-dark security camera with a few interesting features, mounted on the starboard winglet near the mast.

One of the most common bits of advice you hear when contemplating extended travel in tiny boats is, “Carry a radar reflector!” This is fine in theory, but the standard 12″ spherical corner reflectors are too big and clunky for use in the Microship environment. The performance compromise for this tiny boat is a sleek cylindrical unit called the Mobri — available in 4 configurations for various sizes of boats and different mounting constraints. I chose the M2, which is 2″ diameter and 23″ tall, and am mounting it on a block that also carries a little Aqua Signal sternlight (to be retrofitted with white LEDs, of course!).

The deck-completion project led me on a long quest to identify all the skyhooks that will comprise the antenna farm, and one issue was cellular. The Globalstar satellite phone (a whole section on that will be in the next issue, once I have some experience with it!) cycles through three operating modes as needed — digital cellular, analog cellular, and LEO birds. The satellite radome is on the stern, but we needed a cellular whip — preferably dual band so we have the option of 1900 MHz PCS as well as 800 MHz service. The perfect unit, only 4′ tall, turns out to be the 5410-XT from Shakespeare, for which we are most grateful!

Our final sponsor-huzzah this issue goes to Don Douglass and Reanne Hemingway-Douglass, an amazing couple over on Fidalgo Island who publish the Exploring series of cruising guides to the Northwest… replete with hundreds of waypoints. They’ve spent years exploring every anchorage between here and Alaska aboard a Nordic Tug, and have captured massive detail without sacrificing readability (this is quite an art, for many cruising guides either put you to sleep or rhapsodize without useful content). Their book about GPS is also the best I’ve seen (going far beyond the usual basics), and other volumes in their nautical product line include the gripping tale of pitchpoling near Cape Horn. Great stuff!

In media news, we’re keeping a low profile until we’re ready for on-water photos, but we’re excited about the upcoming piece in Wired that is now tentatively slated for June. I’m also pushing deadline on a mobiling feature for the June 73 Magazine, and we won’t even TALK about how late I am with a series for Dr. Dobbs Journal… suffice it to say that we’ve been waiting for the server design to stabilize, which is actually getting close. I suspect the upcoming rollout and 2-week test sail (the long-awaited “Previews of Coming Attractions” tour) will spark a succession of news bits. I’ll keep you posted…

The Nomadic Research Labs homebase has grown significantly since our last update. Not only have there been major lab improvements (most notably a 115,000 BTU heater and a layer of R-19 atop the original R-13), but we also have more land. This wasn’t our plan, but we discovered that the owner of 5 wooded acres immediately adjacent to our long skinny 6-acre parcel was considering offers from loggers… including the horrifying possibility of a new neighbor from hell clearcutting the 100-year-old fir/cedar/alder forest to pay off the land and then plopping a doublewide in the resulting stump farm. This was too horrific to contemplate, and the owner was incredibly gracious about giving us first right of refusal despite higher offers from the land-rapists, so we agreed to buy it.

For hand-to-mouth freelancers with infinite cash sinks called “boats” this is easier said than done, but between Natasha’s old investment account languishing in the UK and my luckily timed purchase and sale of SCON, ISCO, and NGEN, we managed to pull it off. We now have 11 acres of forest, and I’m wearing a wrist brace to ease the RSI I contracted from over-exuberant trailblazing with hand tools. (Our trail network is comprised of Edward Boulevard, Superconductor Alley, Titcombe Lane, and Anchor Rode.)

Hey, don’t forget our Geek’s Vacation program! We welcome volunteers, and a long-term fantasy is to have treehouses for guests scattered through the woods, connected, of course, by a wireless Intreenet.

You must be logged in to post a comment.