Building a Mobile Digitizing Lab

Here in late 2022, as a sort of technomadic swan song, I have embarked on a new adventure in mobile geekery. There will be no pedaling this time, nor is this another floating extravaganza of boat hacking and nautical gizmology. Instead, I’m creating a 48-foot mobile laboratory packed with the tools of my trade… digitizing ancient media and creating tools for its distribution.

This post introduces the machine, and over the next few months I’ll be producing YouTube videos about the rolling substrate itself, power systems, packaging, arcane media machines, and digitizing processes. There are a few twists that should make this fun, including a novel business model and companion mobile electronics lab. But first, let’s take a look at this new rig.

Lighting the Fire

For the past few years, my attention has been focused more on Harbor Digitizing than the 50-foot Datawake that I thought I would be cruising by now. This business began as a way to amortize the film scanner that I bought to explore my father’s movies from the forties, but such things have a way of taking on a life of their own. The scanner gave way to a new version, I added a dozen consumer and professional video decks, threw audio tapes into the mix, set up monitoring tools, and built a system to capture slides & negatives as RAW files. Employees appeared, networked systems got plugged into 160 terabytes of NAS, I found help with adulting, and clients keep arriving…

While all that was unfolding, my life-long fascination with mobile labs and consoles flickered continuously in the background, snapping into focus with this new project. Instead of puttering into my dotage operating a digitizing emporium in an expensive tourist town, why not re-create the Traveling Circuits and have a few adventures, rolling into communities and staying around long enough to archive local history?

So this is what we are doing, and it is not as insane as it sounds. It pushes my geek buttons (of course), but more than that, one of the things I have noticed over the years is that most folks aren’t interested in dropping irreplaceable family history into the mail. That is how I got into this, in fact: back in 2005 when I inherited my dad’s boxes of 8mm films, it didn’t take much online research for me to start getting nervous about shipping the reels off to digitizing vendors. While there are obviously some excellent ones, I read too many horror stories about quality issues, scrambled originals, off-shoring to cut costs, and boxes of film lost in transit. At Harbor Digitizing, I hear it all the time… “wow, I can’t believe you are right here – we really didn’t want to ship these.”

For that reason, most of my business is local; some folks have even driven up from the City with boxes of media to ensure a proper chain of custody. Until digitized, these “single copies” of historical images violate every backup protocol and are worth handling carefully. This includes the collection of old photos and films that almost every family has tucked away, vulnerable to environmental degradation, fire, or inadequate estate planning.

Scaling the Substrate

My wheels have not always been human-powered, you know… five times since 1980 I have had “motherships” that packed collections of geeky toys into rolling substrates, culminating a decade ago in my Polaris mobile lab. That was based on a 24-foot Wells Cargo trailer, which softened the transition from my Camano Island forest to a new life aboard a sailboat. After that adventure, it sat idle for many years… and is now about to become auxiliary shop space for messy work, machining, and parts inventory:

But I need something much bigger for the digitizing lab. By contrast with that svelte little rig, my new trailer is a behemoth reminiscent of my 580-pound bicycle. It’s 48 feet long, made for hauling race cars, and is very shiny. In addition to open space for my equipment, it contains a comfy bathroom with shower, beautiful lighting, power distribution, and a generator compartment with 4500-watt Onan. The GVWR (maximum weight fully loaded) is a stunning 21,000 pounds.

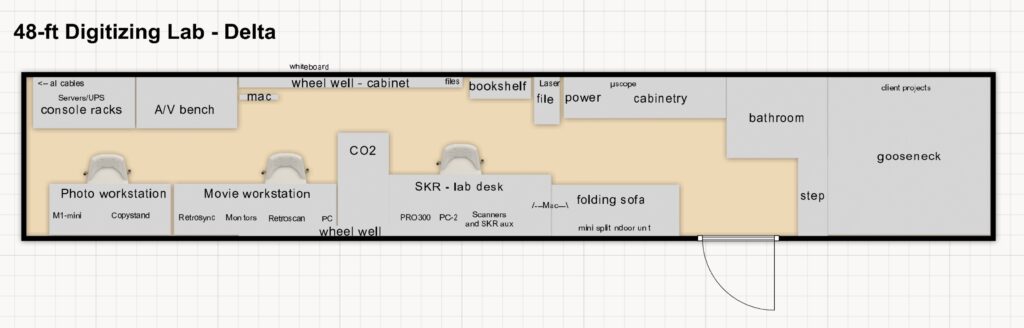

The flash of the racing circuit was not on my list of design specifications, but neither was waiting a year for something to be custom made. The beast in the photos should be perfect for this project, with a layout that gives us 30 feet of workstation space, 10 feet of equipment racks that roll out for service access, dedicated closet for a grid-tied power system, stowage for client jobs in progress, office tools, and a place to relax. We’re adding mini split and diesel heaters to the existing HVAC system with two roof units, and bringing in 50-amp split phase power and gigabit fiber… both of which can be unplugged and replaced by Lithium and Starlink when the mobile lab hits the road.

This is very geeky, intimidating to tow, and getting ever heavier… we just loaded 918 pounds of Uline industrial tables in addition to the lab bench visible in the photo. The “streetside” console region has swivel-locking casters that allow it to roll into the aisle, opening up a 3-foot service-access hallway behind the systems. This will be fixtured to the wall with E-track when it comes time to take it for a spin, and on the other side is 14 feet of workstation space.

The workbench assemblies have such tight tolerance that the last one snapped into place with less than 1/4 inch of clearance, and the next article about the system will detail the lab furniture. Those casters fit perfectly, and the two benches are about to be bolted together to move as a unit.

The development site on a dear friend’s land is a “campus” of three rigs. In addition to the 48-foot beast, my old 24-footer will carry parts inventory, electronics fabrication workspace, ham shack, mini machine shop, and tools… while a 32-foot fifth wheel will provide on-site comfort space. Keeping the two labs separate is a huge benefit, as it prevents hackage from spilling across every desktop.

A Brief Look at the Tools

At this writing, I am still building furniture and designing support systems… while the digitizing business continues for about another month in the sweet little building in town. Here’s how the mobile workspace is shaping up:

When you walk in the front door, the bathroom/shower is dead ahead, and the “gooseneck” area to the right is filled with red baskets of client projects. Just to the left is a counter with checkout terminal, lab microscope, monitor for previewing footage, and wall-mounted displays for home automation and power/network status. Aft of that is a closet that holds a rack of 48V lithium batteries with Victron power hardware, and after that is a file cabinet with laser printer on top followed by thin cabinetry over the wheel well.

Across from all this is a folding sofa next to my desk… with the main Mac on an arm that lets me alternate between slouching and swivel chair. Desktop scanners for documents and slides fill the surfaces, along with the usual computer stuff. This segues into a secondary PC, then the Canon color printer that we use for photos. Not shown is a small tool cabinet to keep clutter under control.

The wing carries a 50-watt water-cooled CO2 laser for packaging and tagging, with forced air to a roof vent via inline fan, and under that are two short file cabinets for raw materials and finished goods. Walking around the demi-wall at the end of this zone takes you at last into the Hall of Geekery.

To the right as you head aft is the rolling 72U rackspace and A/V bench mentioned above, allowing rear access for surgery (all cabling to the trailer exits via the rear corner). Across the hall we find the movie workstation with heavy-duty PC and related tools, including a dedicated machine for sound film… and finally a mirrorless camera on a copy-stand, tied to an M1 Mac for processing slides and negatives.

The end wall is a ramp door that can be lowered on nice days, and scattered about the lab are all those other random components… studio monitors and subwoofer, tucked-away office supplies, shipping equipment, and so on.

Viva nomadness!

You must be logged in to post a comment.