BEHEMOTH

Big Electronic Human-Energized Machine… Only Too Heavy (1989-1992)

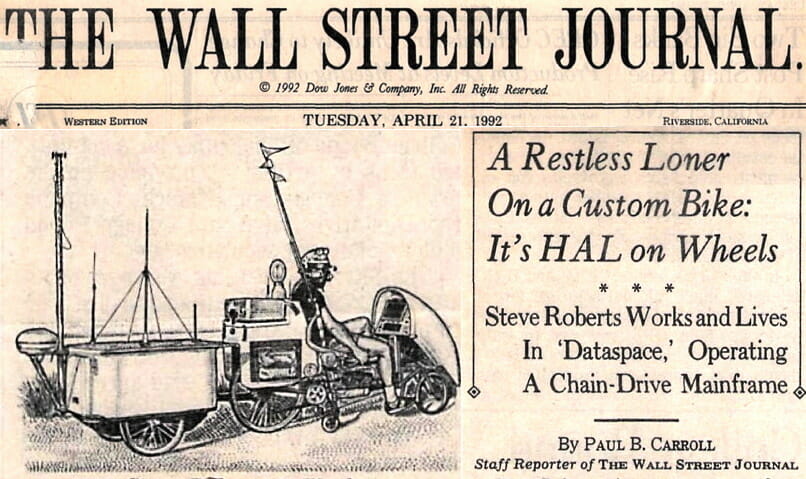

It was 1989, and after 10,000 miles on the Winnebiko and another 6,000 on the Winnebiko II, the road had become my equivalent of living room walls — the network my neighborhood. Being a high-tech nomad had become my identity… I was that bearded writer who pedaled a computerized recumbent bicycle around the US while typing on the handlebars. It must have driven my parents crazy.

For six years I had been wandering, collecting stories, doing interviews… frolicking in this new world I called Dataspace where physical location was less relevant than one’s choice of network providers. This was a very addicting lifestyle, and I survived by putting out a journal called Nomadness, selling my Computing Across America book, and freelance writing for magazines.

But it was frustrating. Technology was moving fast — much faster than the ambling pace of a guy on a bicycle. I had become a spokesman for the very gizmology that was leaving me behind, stuck in the slow lane, getting whiplash from rubbernecking the miracles zipping by and not having nearly enough lab time to keep up. Something had to be done; what I needed was a new machine… one with a software-defined architecture, a set of resources that could be reconfigured on the fly, a glass cockpit, more power, more communications, more file storage… more everything. I needed this:

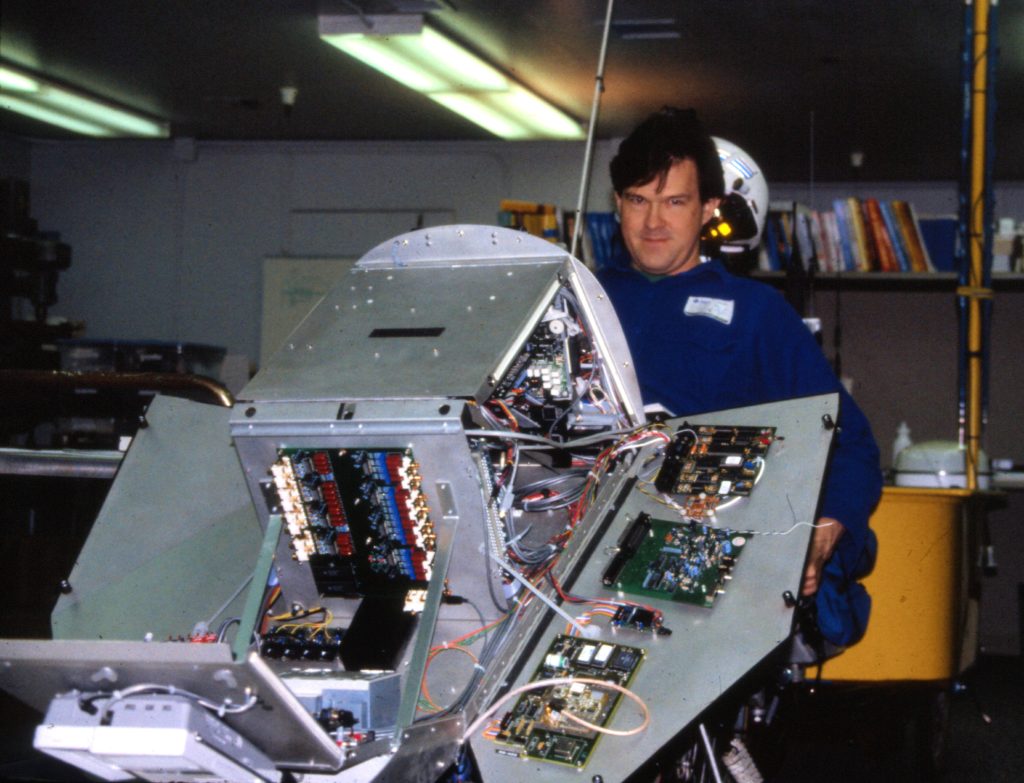

Building BEHEMOTH was a 3.5-year project, an epoch of total immersion in labs in Palo Alto, Milpitas, Santa Cruz, Soquel, Scotts Valley, and Mountain View… diving into fiberglassing, sheet-metal fabrication, machining, FORTH software, system architectures, harsh-environment packaging, networking, bike tech, power management, embedded systems, audio processing, haptic interfaces, antenna design, and more. I had about 160 corporate sponsors (itself a considerable management project, discussed here), along with over 45 volunteers who contributed their brilliance and skills. This was huge, looking back from a quarter century later; a mini-NASA emerged in the lab donated by Sun Microsystems — a dedicated team of geeks driven by the obsession of machines flickering to life, novel architectures, and the thrill of integrating the best available technologies into something that had never before been attempted. (Here is a little on-the-road scenario that explains the insane passion that kept this going.)

The project hit critical mass in 1990, when the folding console and fiberglass trailer were done enough to provide a development substrate. Übergeeks came to the lab every night after work and poured their hearts into the system, and it was like being the conductor of an orchestra consisting entirely of virtuosi. I was surrounded by teachers who gave me a multidisciplinary engineering education while helping bring a mad, abstract vision to life. (The series of 18 Bikelab Reports tells the tale of that epoch from late 1990 to early 1992, with lots of tech details about the systems, and this article in Discover captures the scene.)

A BEHEMOTH Primer

Clearly, building this contraption was an entertaining science project, but what does it actually do?

Basically, BEHEMOTH was to be a collection of all the geeky tools I could imagine, integrated into the limited user interface available while pedaling a bicycle. Most gadgets are made to stand alone or operate in specific environments, but I wanted to pull off a tour de force of usability design and roll ’em all into one system. But how?

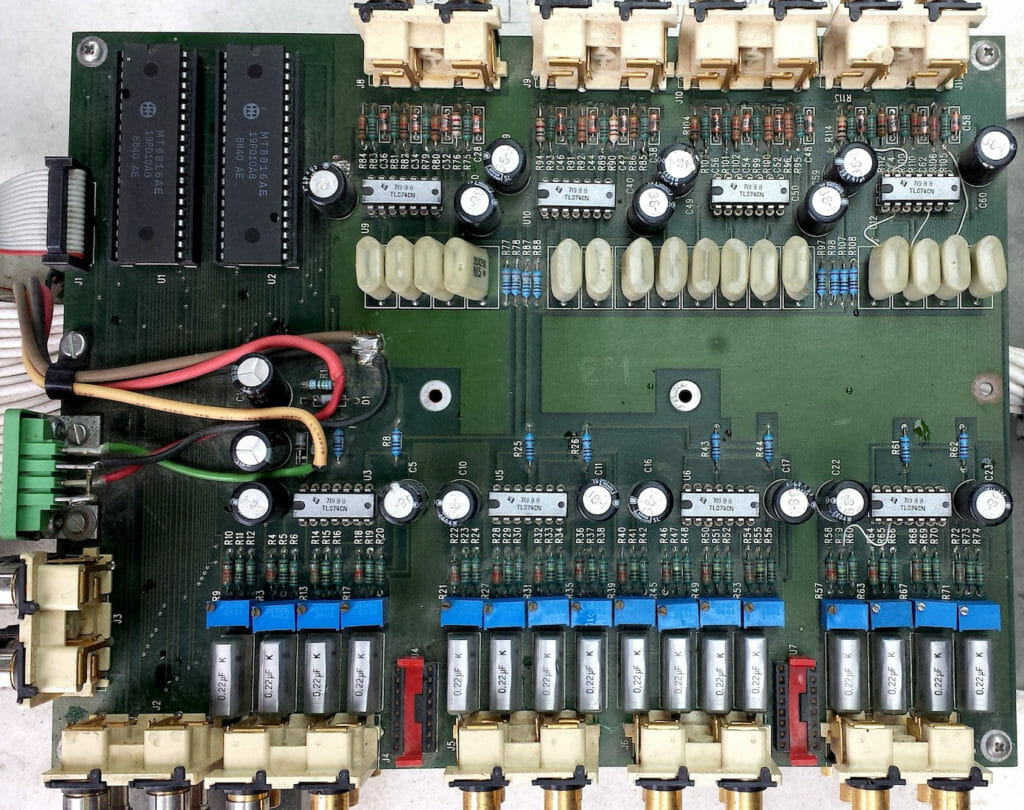

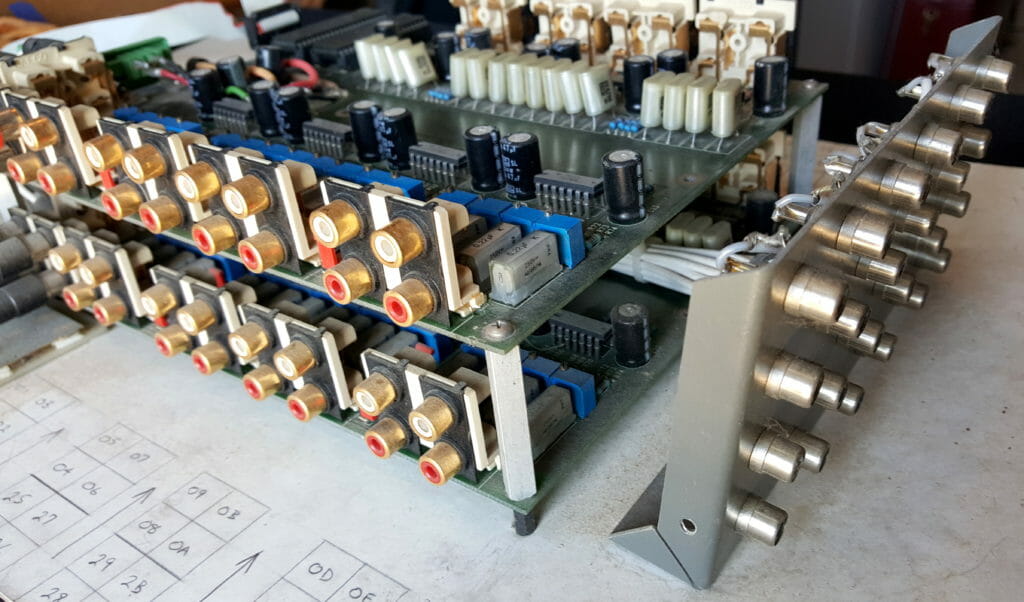

The bike had crosspoint networks of line-level audio and serial data, letting anything talk to anything with a simple command. Similarly, there were lots of logic-level power switches in all three equipment enclosures, so every device could be powered on under software control when needed… and of course there were tons of random inputs and outputs for sensors and control (both analog and digital). All of this was managed by a trio of 68HC11 bicycle-control processors located in the console, the enclosure behind the seat, and the communications bay in the trailer. So whenever I wanted to integrate some new device into the bike, all I had to do was throw away the standard packaging to cut weight, adapt its power supply to my standards, hook it up to network and control-system ports, document it, and write a bit of code. Easy!

Suddenly, all sorts of things became possible without needing a control panel with dedicated switches and LEDs, as I had on the Winnebiko II. Every device could be expressed as a few addresses on networks, and could be made to dance with a bit of FORTH code. This allowed spinning up all kinds of interesting applications that were not anticipated before launch, leveraging the power of a whole range of products by blending them into a meta-system.

At the human end, there were a few application environments for biketop publishing, control, security, communications, databases, and so on. The “big iron” was a SPARCstation in a Zero case behind the seat, equipped with an exotic cellular modem to reach the newfangled Internet that had recently burst on the scene. But I didn’t use that while pedaling; my main work environment was a console Macintosh that drew much less power, controlled by an ultrasonic cursor control that tracked my head position and a binary chord keyboard built into the handlebars… with two microprocessors translating all this into something that the Mac believed was a desktop keyboard/mouse. The cursor followed my nose and text flowed from my fingertips, all while cruising country roads. (“Texting while driving” was not an issue back then, and I may have been the first to do it.)

The user interface was immersive. A heads-up display (720×280) was owned by a 286 DOS machine, and that was my view into the bicycle environment as well as a collection of utilities. There was a 386 for CAD in a screen under the Mac, and a hacked Toshiba laptop running the smaller screen on the console just for a scrolling FAQ when parked. And a speech synthesizer kept me current with notifications from the Bicycle Control Processor, not to mention being a key part of an elaborate security system (talking locally to anyone detected touching the machine, and, if lat/lon changed without the right password, telling the police via 911 that “I am a bicycle and I am being stolen. My coordinates are….”)

Anatomy of a Unixcycle in SunWorld can give you a deeper look at the bike network… and Mr Protocol wrote a delightful piece about the bike in SunExpert.

The console was only one of three networked equipment enclosures. The RUMP behind the seat (Rear Unit of Many Purposes) carried audio, security, helmet interface, the SPARCstation, microwave motion sensor, embedded radio gear including data links, and one of the three crosspoint nodes… and there was an active head-cooling system with a 7-liter tank and a peristaltic pump to circulate ice water through the helmet liner and let my body operate more efficiently on hot days.

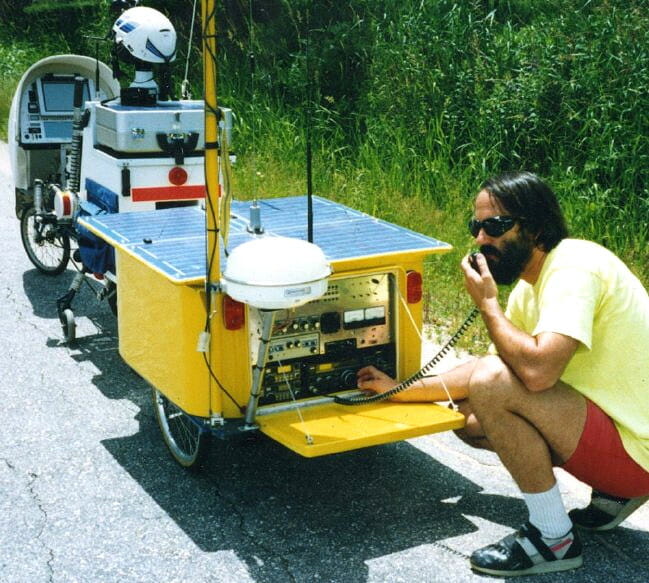

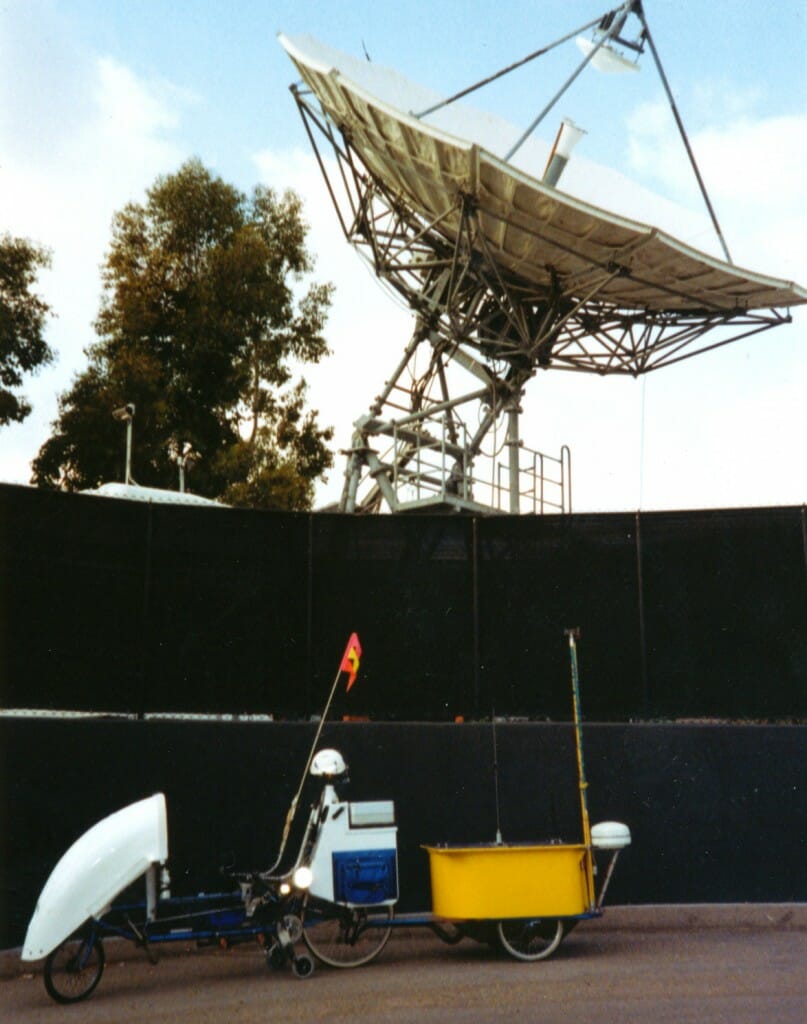

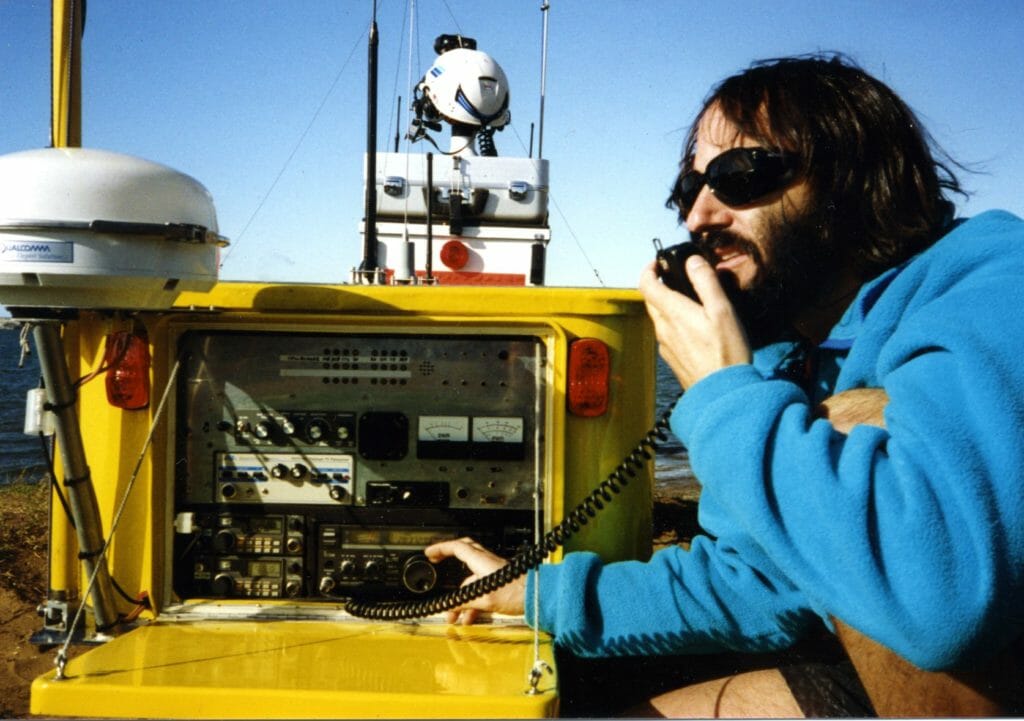

The yellow WASU (Wheeled Auxiliary Storage Unit) carried a 19″ rackmount communications bay with fold-down door… shown in the photo below. This included HF, multimode VHF and UHF, amateur television, and other gear, along with an embedded cellular phone with interfaces to modems, fax, credit-card verifier, cordless phone, and answering machine. The white dome is a Qualcomm satellite antenna that gave me 24/7 email connectivity (in 1991… slow but magical). Taillights were homebrew LED, and the trailer carried two of the three 15 amp-hour batteries along with charge controller for the 72-watt solar array or shore power.

A folding dipole antenna on the BYP (Big Yellow Pole) gave me global coverage on the HF amateur radio bands, and three other antennas on the solar lid took care of VHF/UHF, cellular, and security pager. The trailer body was made of cellulose-core, silicon-matrix, polyester-filled composite (CSPC)… or fiberglass over cardboard (which is also how we fabricated the RUMP enclosure, though the fairing over the console was built from a custom mold).

Of course, all this didn’t come without cost. Among other things, I had formulated the Roberts Law of Applied Mobile Gizmology: If you take an infinite number of very light things and put them together, they become infinitely heavy. What I had initially called the Winnebiko III became the backronymic monster BEHEMOTH — “Big Electronic Human-Energized Machine… Only Too Heavy.” The total weight including all the stowed gear was 580 pounds. Plus me!

This called for a complete re-thinking of the bicycle itself, not just a new console grafted onto the trusty frame that had already carried me 16,000 miles. I needed technology to compensate for the weight of all the technology. Bikelab Report #9 from April, 1991 describes the bike mechanics in detail, including the 105-speed transmission and braking system… but I also required landing gear that could be pneumatically deployed to let me slowly crawl up hills in the 7.9-inch ultra-granny. Having an air compressor and aluminum tank also powered serious truck horns that saved me a few times.

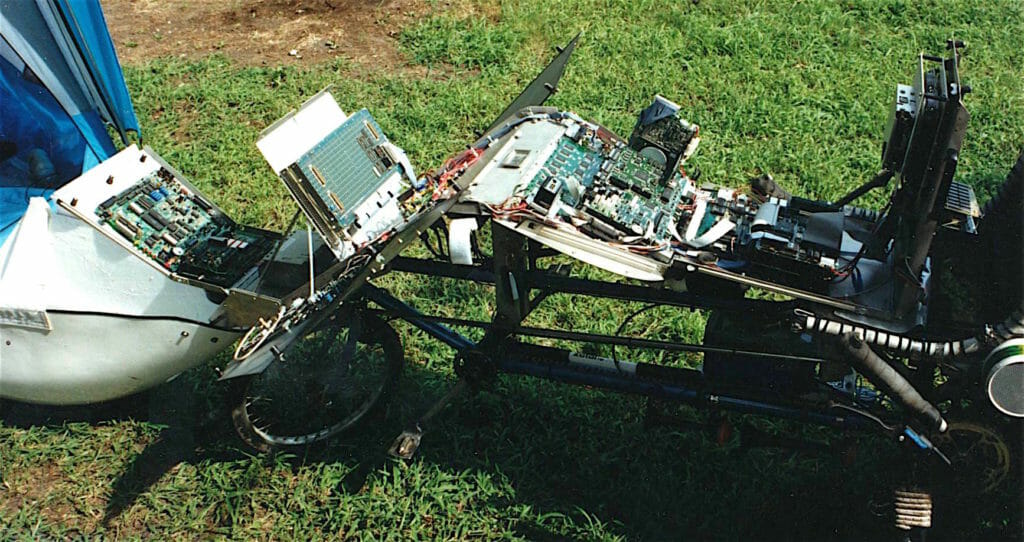

The years were passing, but by July 1991, all the pieces were in place… the photo above was taken just before trucking the machine to Omaha to begin the massive RAGBRAI ride across Iowa with 10,000 other cyclists, a “trade-show deadline” of sorts, keeping me focused on the calendar despite the constant temptations of creeping featuritis and the BEHEMOTH Effect (“hey, this is cool. I wonder how I can use it on the bike?”).

Of course, I was long out-of-shape, the bike was ridiculously heavy, and lots of things had not yet been tested… two days into the ride, a failed hub required a field-expedient repair that pinned it together with bits of spokes hammered into holes drilled into the hub body (naturally I carried a Makita electric drill). I slowed down and let RAGBRAI whoosh past without me, languishing on a Winterset farm for a few days where I did a QST interview… then continued east at a languid pace, making my way up through Illinois, visiting Fermilab, dropping in on companies, and meeting a net friend for a dreamlike trek through Wisconsin and up the shore of Lake Michigan. That water… tempting me…

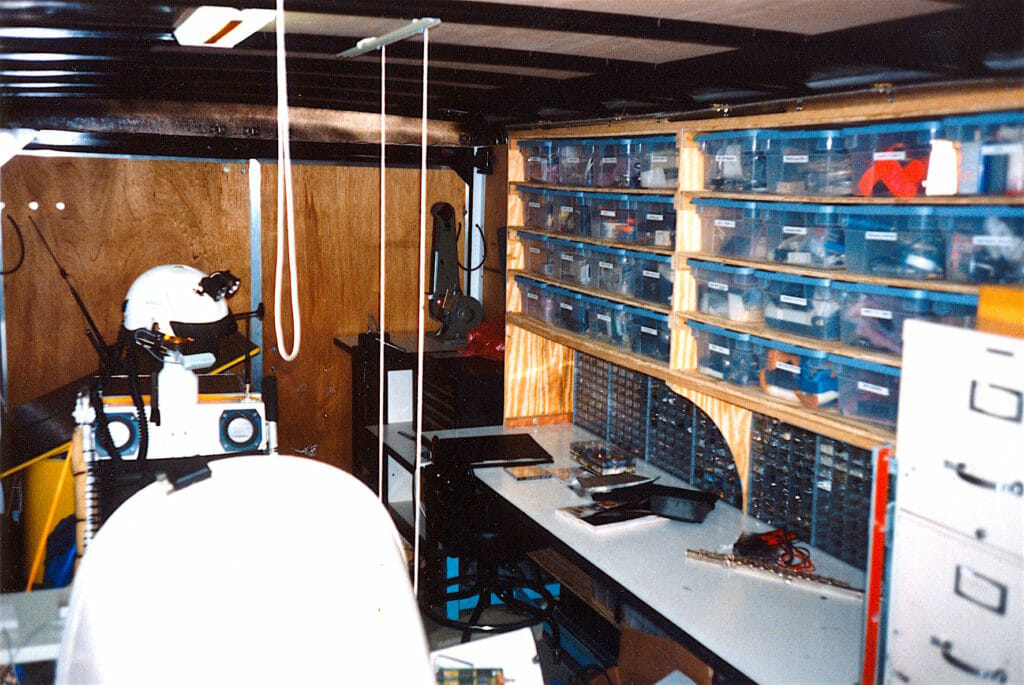

It was wonderful being on the road, but the tech was unfinished. I bought a trailer and set up a mobile lab with the idea of continuing bike development while traveling the country, doing speaking gigs, visiting sponsors, and going for rides in gorgeous places. As I quipped at the end of the dreamlike link above: “And then… back to Silicon Valley to bring the function-to-weight ratio up to a level that will make this even more fun, if that’s possible. As I said, I’m having thoughts of watercraft, but BEHEMOTH has to pay his dues first… there are miles to go yet…”

If only it had been that tidy.

I found my way back to the Bikelab to finish up bike loose ends and outfit the mobile lab, moved tonnage into storage, then began criss-crossing the country in the Mothership, bike docked in the middle of lab equipment, rumbling around on a breathless media/speaking schedule. Most of the BEHEMOTH rides involved TV cameras (including a full hour on the Phil Donahue Show in 1992… video embedded at the link). Meanwhile, the Microship was becoming an obsession. Imagine… BEHEMOTH with hulls…

From that same day, I gave a little walkthrough demo of the BEHEMOTH console. Embedded here is a 4.5-minute video digitized from the original B-roll on U-Matic tape:

BEHEMOTH Feature List

Console

- Macintosh 68K (control GUI and primary workspace)

- Bicycle Control Processor (FORTH 68HC11)

- Ampro 286 DOS platform for CAD system

- Toshiba 1000 repackaged laptop for scrolling FAQ

- 80 MB hard disk space

- Audapter speech synthesizer

- Speech recognition board

- Trimble GPS satellite navigation receiver

- Audio and serial crosspoint switch networks (homebrew)

- PacComm packet TNC (VHF datacomm)

- MFJ 1278 for AMTOR (HF datacomm)

- Diagnostic tools (LED matrix, DPM, etc)

- Handlebar keyboard processor

- Ultrasonic head mouse controller

- Icom 2-meter transceiver; dedicated Larsen half-wave antenna on seat

- Radiation monitor

- Cordless phone and answering machine on RJ-11 bus

- Folding 6-segment aluminum console

- Fiberglass fairing

RUMP (white enclosure behind seat)

- Stereo System (Blaupunkt speakers, Yamaha 18W amp)

- 10 GHz Microwave motion sensor (security)

- UNGO physical motion sensor (security)

- Rump Control Processor (FORTH 68HC11)

- Audio crosspoint network, bussed to console

- Ampro DOS core module for heads-up display

- LED taillight switch-mode controller (including turn signal logic)

- Single LED taillight cluster

- Motorola 9600-baud packet modem for backpack link

- 7-liter helmet-cooling tank and pump

- Personal accessory storage

- Air compressor for pneumatic system

- 15 amp-hour sealed lead-acid battery (1 of 3)

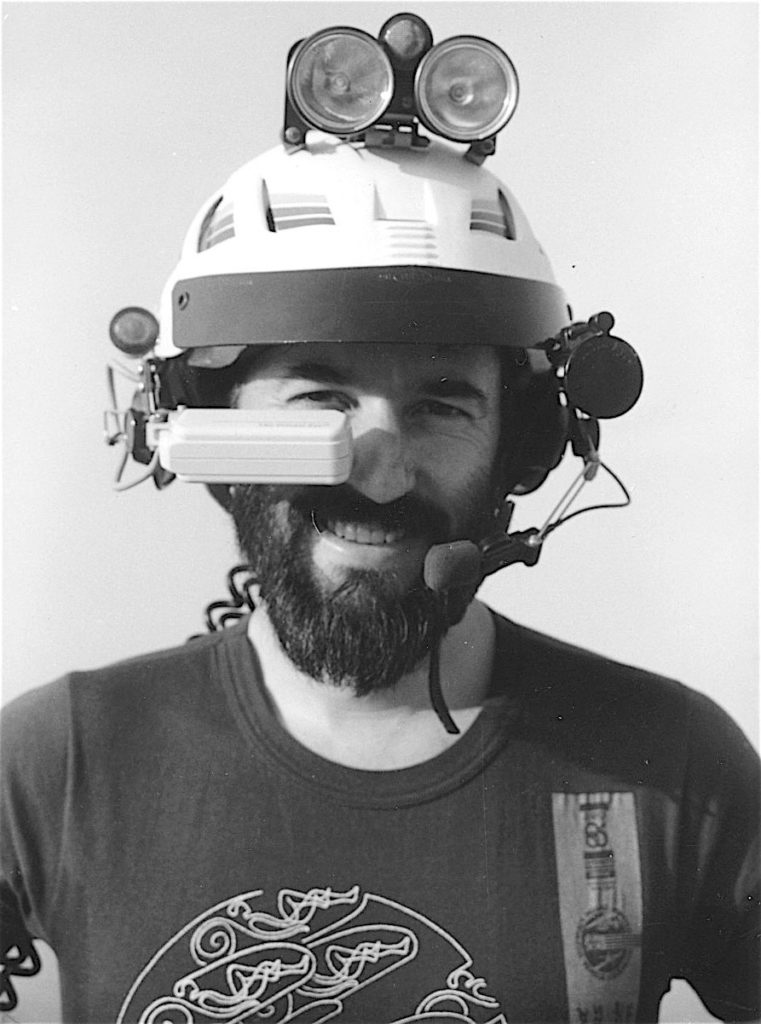

Brain-Interface Unit (Helmet)

- Reflection Technology Private Eye display

- Ultrasonic head-mouse sensors

- Helmet lights (2)

- Life Support Systems heat exchanger for head cooling

- Setcom headset with boom microphone

- Rear-view mirror on gimbaled mount

- Jacks for stereo ear-insert headphones

SPARCpack (aluminum case atop RUMP)

- Sun SPARCstation IPC with 12MB RAM and 424 MB disk

- Sharp Color active-matrix display

- Motorola 9600-baud packet modem

- 10-watt solar panel

Trailer

- 72-watt Solarex photovoltaic array (4.8 Amps at 12V)

- Qualcomm OmniTRACS satellite terminal

- Ham Radio station:

- Icom 725 for HF

- Yaesu 290/790 for VHF and UHF

- AEA Television transceiver

- Audio filtration and Magic Notch

- Antenna management and SWR/power meters

- Automatic CW keyer

- Outbacker folding dipole antenna on fiberglass mast

- Dual-band VHF/UHF antenna

- Oki cellular phone, repackaged and integrated

- Telebit CellBlazer high-speed modem

- Telular Celjack RJ-11 interface

- Credit card verifier for on-the-road sales

- Trailer Control Processor (FORTH 68HC11)

- Audio crosspoint network, bussed to console

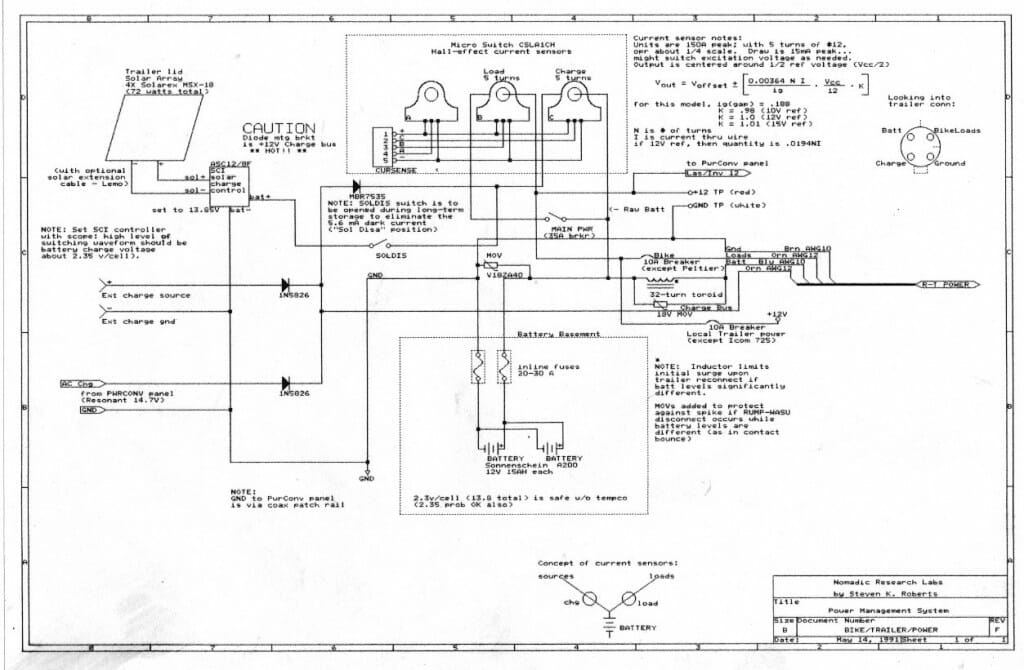

- Bike power management hardware

- Two 15 amp-hour sealed lead-acid batteries

- Security system pager

- Canon BubbleJet printer

- Fluke digital multimeter

- Mobile R&D lab, tools, parts, etc.

- Makita battery charger (for drill and flashlight)

- Microfiche documentation and CD library

- Camping, video, camera, personal gear

- Fiberglass-over-cardboard composite structure

- High-brightness LED taillight clusters

Bike- and Frame-Mounted Components

- Custom recumbent bicycle

- 105-speed transmission (7.9 – 122 gear inches)

- Pneumatically-deployed landing gear

- Pneumatic controls, pressure tank, air horn

- Hydraulic disk brake

- Under-seat steering

- Handlebar Chord Keyboard

- CD player

Technomad Dreams

I added a kayak to the Mothership, and hit the water whenever I could while visions of the future Microship began to take shape. The more I talked about the bike, the more I thought about the boat. All I needed was a lab near water, a quest that merged with the rambling open-ended speaking tour that consumed much of 1992-3. One nice video that happened during this period was Next Step on the Discovery Channel, airing in April 1993… just before I landed at UCSD to begin building the little trimaran.

Other Resources

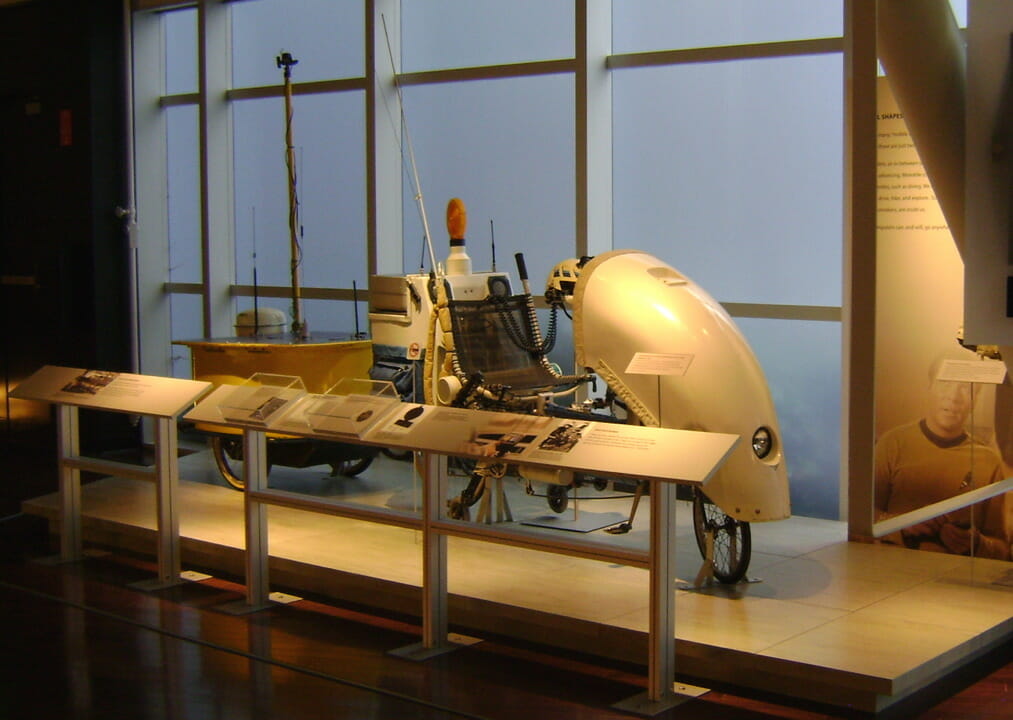

The story above contains embedded links to a lot of material, but there is much more in these archives including the set of 18 Notes from the Bikelab including a FAQ that captures the intensity from the lab just before departure. Here is all the BEHEMOTH Media Coverage, along with a list of speaking engagements. Many years later, I donated the bike to the Computer History Museum where it is now on permanent display, and one of my most energetic and detailed talks was this one at Quantum (with the bike on stage and a lively audience of engineers). My talk at BBN in 1992 was also very techie and playful.

Next… A Decade of Microship Development (1993-2002)

BEHEMOTH Bikelab reports

This short series covers some of the tech details of the bike, published online while the project was underway (1989-1992). These open in new browser tabs…

You must be logged in to post a comment.