New Microship Substrate

A huge event took place in 1995 — the abrupt transition to Microship 3.0. I had already abandoned the original kayak-based system and its variants, and a Puget Sound adventure on a small commercial trimaran (Fulmar) revealed many deficiencies that called for a larger boat. This article was posted to my broad Nomadness distribution list, which at the time was a different thread than the Microship Status Reports. The latter were detailed and fine-grained for a technical audience; these had a much larger scope and went out to over 4,000 people via a listserve.

The Nomadness Notes, Issue #27

by Steven K. Roberts

San Diego, California

May 30, 1995

“If you take something apart and put it back together enough times, eventually you will have enough parts left over to build a second one.”

— wisdom from Out There

The Microship Finds a New Substrate!

In our last episode, so long ago, Faun and I found ourselves aboard a pair of tiny Fulmar-19 pedal/sail trimarans, plunging through the flying spray, soupy fog, unexpected calms, and interesting currents of the Pacific Northwest. Not only was this a memorable adventure, but it substantially changed the very concept of the Microship.

One of the most notable revelations was that full-time cruising for two requires, at minimum, a boat big enough for two to sleep on (and not just in swimming-pool conditions). When you add the need for a robust array of systems, solar power system with electric thruster, communication tools, and enough provisioning to realistically consider passage-making… then toss in decent rigging, essential safety equipment, and a healthy dollop of seaworthiness… you have just reinvented the yacht. Despite the romantic appeal of a wee bicycle-scale micro-trimaran, the issues of survivability win the toss.

Upon our return from the Fulmar adventure, therefore, we began a quest for the perfect boat (within our budget, alas). I flew to Texas to sail a Stiletto 27 catamaran (the photo above), talked to sellers of 25- to 35-foot cats and tris across the land, and collected study plans from noted multihull designers of the Pacific Northwest. Faun and I looked at a MacGregor 36 catamaran, sketched interiors, made cardboard models, and found ourselves gravitating toward a sleek Hughes 30-foot cylinder molded tube cat that we could have had built in Oregon… only to discover after drawing a hull cross-section on the wall that it would be like living in a parallel pair of narrow tunnels. We backed off, recognized the structural advantages of a tri, and homed in on a Marples Seaclipper — something that could be realistically homebuilt of plywood and epoxy. But the 2-year, $15,000 investment necessary to arrive at the START of electronics packaging was, despite interesting learning curves enroute, a daunting reality. The calls and research continued… somewhere there had to be a boat that was complete enough to give us a head start but not so complete as to be unaffordable.

Then came a stroke of luck. I was speaking one afternoon with Mike Leneman of Multihull Marine in Marina del Rey, and he was explaining that what I obviously need is an F-31 “kit.” For only $52K, I could buy a sleek folding trimaran shell with no interior or rigging… and hey, it comes with a trailer! I chortled and told him that I’m a freelance writer who has managed previous technomadic projects through the twin miracles of sponsorship and obtainium, and was about to politely hang up after giving him a capsule summary of BEHEMOTH and the Microship.

“Wait!” he cried. “I have your boat right here!”

A few weeks later (after a 4-day documentary filming with the French TF-1 network that segued into a whirlwind jaunt with Faun to eyeball the boat, retrieve the Fulmar from Seattle, meet John Marples, swap the Libra double kayaks for a lovely pair of rotomolded Storm singles, kayak around Bainbridge Island, sail at Black Butte, hang out with Dave Berkstresser, and speak at IBM in San Jose), I returned to Marina del Rey with Paul Picot, attached the rustbucket trailer and makeshift lightbar to the back of my diesel truck, and hit the freeways at 5 PM. <shudder> (More details in this Microship Status posting from April 9)

All this was every bit as exciting as it sounds, and the net effect is that I am now the owner of an eccentric 30-foot folding trimaran steeped in multihull history… built in 1983-84 by John Walton and Mike Michie just prior to the formation of Corsair Marine (builder of F-series trimarans). Affectionately known as Hogfish, this 3,000-pound boat has no interior accommodations, lacks rigging, and has languished in dry storage for most of its life — sailed only 4-5 times. The carbon wing mast originally built for the boat has become a billboard, but Mike tossed in a 40′ aluminum mast section and a traveler track to get us started on rigging. (That’s the first major project, in fact — finding a rigging contractor to render the ship seaworthy so we can get a feel for the basics before blithely installing widgets that have to make room for winches…)

Construction is excellent — S-glass over Klegecell core; carbon-fiber crossbeams, aft cabin, Lewmar hatches, kick-up rudder, and so on. We have the bow and stern pulpits and various other bits and pieces, but are essentially starting from scratch with rigging and outfitting. Suddenly it all seems more real… and we wander by the storage yard every few days to lounge about in the cockpit and ponder the enormity of it all.

The Fulmar epoch provided an essential reality-check for my original notion of a tiny human-powered craft, while giving us a bit of on-water experience to augment the tame Bay-sails on friends’ monohulls. But the Fulmar is now for sale, and we’re deep into the design of this new system.

New System Overview

This new substrate instantly clarifies some of the mysterious design issues that have remained in a vapor phase since Day 1 of this project. I now know the size constraints of my aft-cabin equipment console, for example, as well as the dimensions of our photovoltaic array and the amount of cockpit display space available. The battery bay, the galley, the head, Faun’s hydroponic garden — all have moved from vague notions to something approaching real specifications.

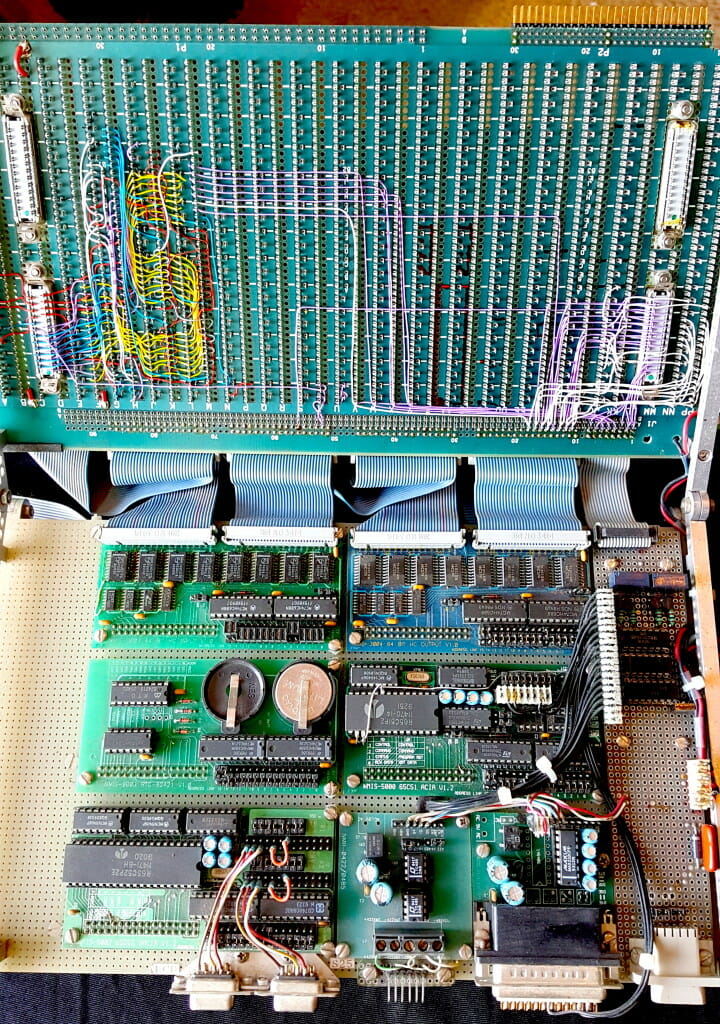

The control systems, likewise, have evolved far past the level described in previous reports of this series. We’ve taken advantage of Bill Muench’s multitasker to pack much more into each FORTH node — reducing their number along with the concomitant packaging and power requirements. Last week, I repackaged the Hub — it’s now a folding affair based on BEHEMOTH’s original bicycle control processor hardware (I know, I know…) — a New Micros FORTH board and backup batteries on the bottom layer; I/O and networking hardware on the second; serial crossbar, LED monitor matrix, and interface hooks on the third. As I write, it’s happily blinking its heartbeat LED and displaying real-time on its mini-LCD… scanning the Audio, Video, and Turret nodes without affecting the interpreter. A simple command redirects either the Hub’s console port or the network itself to the serial crossbar, allowing a fully-functional remote front end via packet radio or other media.

A number of UCSD engineering student projects have helped us reach this point, and many more lie ahead — more clearly defined than ever. The HyperTalk graphic helm has been established, offering an exquisitely simple programming and operating environment that seems tailor-made as a front end to FORTH. The A/V crossbars work so well that they are in daily practical use in the lab, and we’re just now starting to connect security and environmental sensors to make the system useful for watchkeeping and data collection. In short, this epic control network project is now defined enough for us to actually see the big picture clearly… though I’m sure there’s still plenty of hair-pulling ahead! (Photo essay of Microship electronics)

The physical installation in the ship deserves a moment’s mention. The aft cabin is a small room that will be a sort of wrap-around lab — I’ll snuggle into it and find myself surrounded by Mac, Hub LCD, video screen, comm gear, control and monitoring systems, the breaker panel, and so on. The key control and navigation tools will also appear in the center cockpit — on a panel that can be pivoted to allow either of us to stand watch in the forward cabin. Both Faun and I will have wireless “manpacks” that dock on board and give us full control, navigation, and communications off-ship — the core processor and interface board for the prototype was completed last quarter by a spirited team of three young engineers. Wireless AppleTalk takes care of relocating the HyperTalk user interface wherever necessary, as well as all the requisite email and file-handling tasks (we have three Digital Ocean Groupers in the lab, and are running Netscape over them to control the turret and snag images via a ComputerEyes/RT SCSI frame grabber).

The solar array has grown — 36 30-watt Solarex ultralite modules in six clusters. Each cluster is packaged on a trifold panel assembly currently being designed by a UCSD mechanical engineering team, with wires routed through doubly articulated hinges and a Divinycell substrate to handle loading. The assemblies will be attached to the tramps with wrap-around hook-and-loop fastener (in shear mode) that allows full extension, partial retraction when things get breezy, or quick removal and stowage below for security or a bad blow. The modules will be cabled into the ship as separate units, probably jumpered in series groups of 6 and handed off to peak-power trackers that maximize the power extracted under all conditions. The current plan is to have a 48-volt battery bank (with a DC-DC converter charging a 12-volt “house” battery), running a Ray Electric outboard motor. We’ll see. This is a lot of weight for a light trimaran, and we’re awaiting a bit of consultation to get the allowable loading limits.

Enough tech details for now… we’ve been busy, as you can see, but all this is about to be eclipsed by a crisis looming on the horizon.

Where to Now? (help!)

I’ve been at UCSD for two years. I might be here two more — one possible deal would have us port our manpack technology to a project that would pay the rent on a new off-campus lab. But there’s a storm brewing: the 3rd-floor lab in the Engineering Building here is no longer adequate (and no longer available after the end of this quarter!).

And so, as I have done before in these postings with generally good results, I’m sending out a call for help. We have an immediate need for about 2,500 square feet of reasonably secure ground-level space, with a roll-up door tall enough to pass the folded ship (about 13′). We expect to need the space for about 2 years. Nearby water is certainly a plus, as is proximity to a major high-tech center with a good sailing community. If we can live in the space, so much the better — but that’s a deal-breaker in most places and is thus not essential. About half the space is needed for the ship; the rest is labs and offices. And net connectivity is a must, of course.

There are at least four possible models that might work:

- First, a corporate host that benefits from the PR and general excitement of a crazy public techno-skunkworks project — all the better if the company’s products are in some way related to nomadic connectivity or other key aspect of the system. Any number of engineering/consulting/test deals can be folded into this, depending on the nature of the business. (Example: Sun Microsystems, which generously hosted the last 18 months of BEHEMOTH development.)

- Second, an academic host that benefits from the presence of an endless supply of challenging student projects along with active on-site management, practical engineering instruction, and extensive industry contacts. We’ve learned a lot since our first tentative student projects here, and there’s plenty of interesting work ahead in EE, ME, and CS.

- Third, an entrepreneurial relationship that funds the development lab in exchange for the engineering effort and marketing rights on product spinoffs, of which we have a fair-sized list. We’ve never had a relationship like this, but it sounds like a potential win-win with the right entity.

- Fourth, a deep-pockets sugar daddy who thinks this is cool and wants to fund it for the pure pleasure of being involved. We’ve never had a relationship like THIS, either, but hey, we’re flexible…

The key here is that we have to move FAST — possibly as soon as the end of next month. If you have any strong leads or interest along these lines, please let us know ASAP!

Closing Notes And A Wee Bit Of Marketing

I’d like to refer you again to our Web site and a few other resources. Faun (my lovely partner… ah what the hell, I’ll go public: my lovely fiancee) has done a magnificent job on the Microship web server. In addition to all the archives of the Winnebiko/BEHEMOTH epoch, the site carries detailed technical status reports along the lines of the bikelab reports that once went to THIS mailing list. I stopped the frequent mailings because lists of 2,000+ names are way too much work to maintain, but we’ve put out 86 issues so far to a small list of sponsors and project participants… all archived in the Web site. There’s also a good collection of photos, the technomad general store, adventure tales, and tons of other relevant stuff including pictures of Faun.

We’re even getting back into print publication (finally!) — Faun has become a wiz at PageMaker and PhotoShop, and has so far produced three Monographs. These are the full collection of Microship Status Reports and Nomadness Notes since the start of this nautical dementia (to borrow Dave Wright’s apropos term), plus dozens of pictures and drawings to flesh out the text. If you’re interested, drop her a line for a flyer (see below) — I’ll stop short of listing prices and being too commercial in this posting! We also have Microship T-shirts and a few other goodies. (Incidentally, if you’re a subscriber to the print journal Nomadness, your subscription is about to be fulfilled at last with a suitable number of Monographs. PLEASE let us know immediately if your address has changed — paper bouncies are expensive and slow.)

And, as always, I’m on the speaking circuit sort of sporadically — usually accompanied by BEHEMOTH and the Mothership. Our next move will be to have a demountable shipping crate fabricated for the bike so we can realistically take on East-coast gigs without making a major lifestyle change… let me know if this sounds interesting. It’s how we’re paying for rigging and other expensive non-sponsorable essentials. You know what BOAT stands for… Break Out Another Thousand!

With that, I send you my best from the Microship lab, and thank you for your continued interest in high-tech nomadness!

Cheers,

Steve

You must be logged in to post a comment.