Project Delta

When I bought this sexy lab trailer, I was dealing with a red-alert… my business lease in Friday Harbor had become unstable, and it was impossible to find a rental on this rock except for overpriced triple-net absurdities. Erecting a pole building on my dear friend’s land was out of the question (36-week permitting delays, not to mention yikes-cost), so what the hell… time for a new mobile lab!

With 384 square feet of mostly open space, this is a decent substrate… and I assembled a suite of furniture including a 10-foot rolling unit to ensure rear access to the console, another 14 feet of maple-top digitizing workstations, YouTube studio wing, desk with magnetic fixturing, piano drawer, and lab infrastructure. This photo shows the port side near the stern; across the hall is the movie film scanner and copy stand for slides and negatives.

Forward of all that is video production, followed by my primary workspace, scanners, microscopes, office equipment, and print center. There is a closet for lithium battery bank, a bathroom with bidet seat and shower, and an 8-foot gooseneck region for client project storage (as well as massage mat for creaky body breaks). This trailer is a beast, though of course I have yet to actually tow it besides nervously turning it around a year ago to point north on a gravel pad. Was epic.

But even sitting still, this contraption pushes buttons like the ones that launched BEHEMOTH, Microship, Nomadness, and Polaris. There is deep satisfaction in a geeked-out mobile system, an aesthetic that has affected the design of this since the beginning. Even if “mobility” actually translates to “portable in case I need to escape the dangerously poor medical care on San Juan Island” it shapes the system in deeply familiar ways.

There are still some packaging jobs to do. If I get a wild hair this weekend and drag the lab four miles to Friday Harbor, the resulting gizmological gumbo would cost thousands to fix and disrupt productivity for months. I’d need a team with a walkie-talkie, poised in the trailer with pillows and duct tape… springing into action whenever I announce a looming curve. Even if everything more or less stays put, delicate video decks and other machines would really not like road shock.

In addition to fixturing, there are a few other parts of Project Delta...

Upper Deck

One practical headache is the lack of outside attachment points. The flat aluminum roof holds puddles and doesn’t carry body weight, so my original plan to mount 3.5 KW of solar panels on RV-style mounts with cable passthrough is not going to work. Toss in a Dishy, three ham antennas and related fixtures, PTZ camera, Tempest weather station, WiFi AP, random sensors, and terminus of overhead weatherproof cabling to the Gamma electronics lab trailer… and it is a recipe for nasty leaks.

The canonical solution in the cargo-trailer world is a “ladder rack” spanning the full 8-foot width, so my first thought was to just buy one from Amazon… but quality is dodgy. They all seem to ship with junk hardware that shears on installation, and while that’s trivial to fix, poor QC in that department is not a good sign especially when reviewers frequently mention the issue. Worse, there are many reports of aluminum welds snapping under mild cyclic load, something you don’t want while trundling down the highway at 160 kilofurlongs per fortnight with an impatient queue of litigious four-wheelers on yer donkey. So instead, I’m making a frame of 80/20 (an upscale and more precise aluminum-flavored Unistrut alternative), bolted to the upper rails and supporting an elevated platform on cross-members. With an access ladder and clever cable management, fixturing problems should go away.

HVAC and Structural Issues

This shiny Bravo trailer is a thing of beauty, but I was a naive buyer. The word “insulation” means something different to sales guys, and those walls contain only token Reflectix foil-backed bubble wrap and a lot of dead airspace. The roof is thin foam with a bit of light plywood, and the floor is a very nice 3/4″ engineered plywood… with no insulation. So the summers are brutally hot and the winters are cold, even with the marginal pair of Dometic roof units running continuously on their new smart thermostat to keep my equipment in the zone of livability. One A/C is intermittent, thanks to sloppy installation with power supplies flopping around untethered during the cross-country delivery… so on the hot list, so to speak, is daunting installation of a mini-split. But the real problem is still poor insulation, and research reveals considerable differences of opinion about how (or even if) that can be fixed. Most agree that it is too late to open it up and do expanding foam without turning the thin aluminum skins into Michelin Man, and the walls are assembled with adhesives and essentially unserviceable.

Last summer we shaded the trailer with a black fabric sail, and this year we’re planting fast-growing vegetation… none of which goes well with the term “mobile,” but should help. We’ve even fantasized about building a barn around it. Yes, yes, I know… might as well put the rig up on blocks and eBay them fancy wheels. I tried to get this redneck imagery across to Alice the AI, who stacked the blocks separately and decorated them with partial hounds…

The floor is another problem. Part of my negotiation with the dealer (Millennium) was to retrofit the “beavertail” region that, in the original trailer, played nicely with the ramp door to make a smooth entry for low-slung race cars. Of course, I actually wanted a level floor for maximum lab space… so instead of steering me to a suitable office trailer they agreed to retrofit that last six feet with strong 3/4″ plywood matching the rest of the rig, built up with a wedge insert to fill the ramp. The result looked very pretty under the black coin flooring when it arrived a few months later from Indianapolis, and I signed off without thinking so the drivers could catch the ferry and go home. What could go wrong?

Well, quite a lot. The dealer hired some guy who did the job sloppily with soft 3/8″ chipboard, so weak that I have to steer large people away from the area around the slide workstation and feel it give under my step if I don’t stay on the joists. The rolling console immediately started getting trapped in the wells that formed under its wheels, making it impossible to pull it out for service without help, so I added an expensive .25″ aluminum track to keep the casters from sinking through my squishy floor (the others work perfectly on the original flooring). There will be surgery someday, along with an invoice on fancy letterhead, but the poor workmanship has cost me dozens of hours. (In the esoteric reputation-based economy of cargo trailers and social media, it has already cost them two sales.)

There have been a few other issues, like all the AC outlets in the entire open bay being on a single 15A breaker, domestic Romex (!) power cable lying across sharp metal wall cutouts and partially cut through from the delivery trip, and a near-total lack of documentation… but the finish work is sleek and clients love it. It is a well-lit comfortable workspace (in temperate weather conditions), most of the floor is solid, and I have had no significant failures. The dealer threw in a gorgeous Onan generator and a cool folding sofa that I didn’t think I wanted, and my support contact at Bravo has been helpful. So on we go, with more lessons learned (this is my fourth cargo trailer, so you’d think I would have caught some of this before it was too late… but the clock was ticking loudly and I didn’t push back hard enough).

Mobile Lab Automation

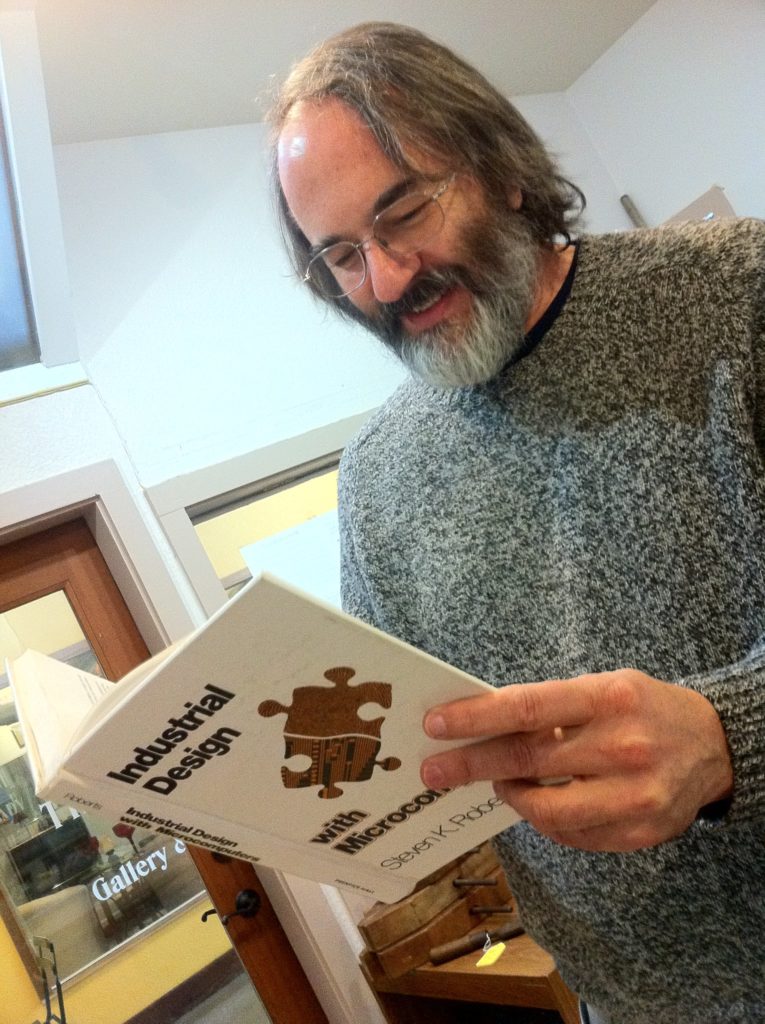

But now for the fun stuff! Most of my gizmological projects over the past few decades have involved data collection and control systems… back in the seventies, when I was doing industrial process automation consulting under the Cybertronics name, this was what I found most engaging. “Business machines” never excited me nearly as much as those that are interfaced to things, and I even wrote an engineering textbook about it in 1980.

The BEHEMOTH bicycle had lots of gadgets that could be stitched together to make magic happen… and the Microship took that to the next level with crosspoint switching matrices and a network of embedded controllers. I now use a similar conceptual architecture in the mobile lab, with tools that allow anything-to-anything connection in the domains of audio, video, and HDMI.

So with all that background, how could I have missed the coolest geek bandwagon of the past decade… Home Assistant? I was even building systems with similar objectives (though not nearly as well) back in the early days of the Nomadness sailboat project, writing Arduino code and deploying a fragile multidrop network of controllers from stem to stern. By the time I was moving to the Dark Side with a big 50-footer, the N2K world had grown to encompass all this and it was getting seriously fun out there. Now it is easy to integrate everything in a domestic environment, with most of the goodies available from Amazon for a song.

There will be a lot about this in future posts, but the nutshell nerdy summary is that I now have an i3 NUC running Home Assistant in a Proxmox VM. A remote hub glows like an electronic candle in the window of my rolling Faraday cage, providing Zigbee and Z-wave gateways along with WiFi and BLE. Off-the-shelf networked widgets are scattered around the compound, providing an astounding number of entities that let me monitor and control almost everything. Automations are easy to spawn, dashboards fit their environment, and I even have remote access while my phone triggers events based on my location. It is insane. Want a roof vent to open when VOC levels climb due to cleaning dusty 16mm movie film with a stinky Edwal-saturated pad during a digitizing run? Piece o’ cake, with an RGB light indicating danger level.

The Home Assistant community is amazingly rich and helpful, and the huge code base is open-source and free from dependence on cloud services. Like many people, I got bitten years ago when parts of my boat’s smart-home system became unstable due to corporate decisions… and it would get flaky when the net connection faltered. HA is free of all that, running on my local server, and there is a ton of good advice in online communities to support the deep and satisfying learning curves.

This will be one of the topics in this blog going forward… there is a new level of integration not limited to traditional lighting, security, HVAC, and energy monitoring applications. I’ve picked up an infrared interface to control my suite of video decks, and I’m getting to know the ESP32 chip to give me hooks into the crosspoint systems and other tools (with a new kind of “programming” that triggers delighted “WTF?” thought bubbles in the air above this creaky paleogeek). This is a unifying environment for my whole system, and I suddenly am motivated to get the electronics lab organized again.

Mobile Time Machine

The excuse for this trailer full of networked retrogeekery, of course, is the digitizing business… and there is a lot going on. What started as a tool for capturing home movies has grown to include slides and negs, every flavor of consumer and some professional video tape, audio cassettes and reels, digital media from the transitional age of miniDV and DAT, vinyl, and shiny discs ranging from mini to macro. We usually put all this converted media onto thumb drives or SSDs, but also use SmugMug and various cloud services, and have even been known to do a bit of editing (including amazing new AI tools).

It’s intrinsically fun, though when I look at my life from the perspective of this archive it is insane… here I am in my seventies, selling off hours in what amounts to a service business immersed in other peoples’ history. All of these machines and fine-tuned processes are documented only in my creaky wetware, and when the day comes for me to shuffle off this mortal inductor the mobile lab will become just a big box of obscure eBayables for somebody to deal with.

This is unacceptable, so I am actively seeking an employee or apprentice. Film and other flavors of retro-media are hip these days, and I like to imagine that some geeky pup will see this as an opportunity to launch a career while playing with amazing toys in the time machine.

It’s always dangerous to predict what’s ahead, but I created that YouTube studio to give myself a new publishing venue. The backlog of technical how-to topics is stunning, and the production station includes a teleprompter with the Sony ZV-E10 camera, Aputure lighting, ATEM Mini for source switching and live production, Czur desktop book scanner that doubles as a downward-looking camera, OBS in the Mac for easy B-roll, video editing environment, and the ability to feed live HDMI sources from anywhere in the lab.

The Microship YouTube channel is not yet monetized… if you subscribe, it will send me a little dopamine hit every bit as exciting as the BEL that was triggered whenever people from out there on the Internet accessed my newfangled Nomadic Research Labs “Mosaic Server” way back in 1993, when the web had a wild west feel. It reminded me of DX’ing on ham radio… “oooh look, Sweden!”

A Paleo-Technomad Swan Song

Speaking of the Olden Days, you may know that my “claim to fame” is the subject of most of this archive: in 1983, I took off on a computerized recumbent bicycle and spent a decade wandering 17,000 miles around the US while using emerging tools to maintain a writing and consulting business. The adventure took on a life of its own, became a career, and spawned other projects; this mobile lab 40 years down the road has its roots in the Winnebiko that permanently resides (in its final BEHEMOTH incarnation) in the Computer History Museum.

Way back middle of that delicious life epoch, I wrote a book called Computing Across America. This was a publishing-industry horror story with editorial musical chairs, contract messes, and malfeasance… and it has been out of print since the late 1980s despite having a cult following and continuous media coverage. Used copies on Amazon don’t do me any good, so it is time to get this back out… there is much more to the story than what made the cut 40 years ago.

This has been a lingering annoyance for over a quarter century, and “working on the new edition” rolls off the tongue like a well-practiced sound bite. But now there is fresh impetus, in addition to simply wanting my legacy to outlive me. Lately there has been a huge increase in publicity describing me as the first digital nomad (although back then, my term was “high-tech nomad,” portmanteau’d into technomad by 1984). A wonderful new book called How to be a Digital Nomad was published in early 2024 by Kayla Ihrig, and she delightfully tells the story of my early adventures, with quotes and tidbits throughout. Also in January, I had an enjoyable interview with Gabe Marusca, discussing this history, and a substantial piece in Bikepacking tells the story with lots of my favorite photos.

This reminds me, painfully, that there needs to be a product again. Computing Across America ended abruptly at the 10,000-mile mark on a publishing deadline… even though the personal and technological narratives yet had miles to go. The story continued online through 1989, with much more satisfying closure as I dealt with The Other Woman and solved the problem of being productive and connected while mobile with the Winnebiko II. Ending the book there makes more sense, though I will of course be unable to resist a geeky appendix (if not another whole book) about the $1.2 million BEHEMOTH Grand Turing Machine that rolled out of the lab two years later.

So with warm thanks to Kayla, Gabe, and many others who have reminded me of the historical significance of this story, I’ve cranked up the priority of the book project… and might even do a reading or two with this fancy new YouTube contraption while working to get it published.

Onward!

You must be logged in to post a comment.