Building complete and cross-country tour

by Steven K. Roberts

Microship Status Report #125

Nomadic Research Labs

Camano Island, Washington

August 24, 1998

“Don’t get mad; get nomadic!”

Dan Burdick

THE BUILDING IS DONE!

I never believed we’d reach this point, actually. Eight months have passed since we rumbled out of Silicon Valley with three trucks and two trailers, bound for the mystical vision of an ideal Microship development lab near water somewhere in the Pacific Northwest. Desperate to get back to the project, we came frighteningly close to everything from a falling-down old shipyard in Blaine to a musty barn with crashable loft and rentable doublewide, but instead fell into a 6-acre slice of sociobotanical nirvana on an island in the Olympic rainshadow. We moved into a well-insulated and stylish little house and built a 3,000 square foot pole building back in the woods, with a hushed 750-foot sylvan commute connecting the two. It still seems dreamlike and surreal… like visiting the home of someone whose lifestyle makes me ache with longing.

I’ve delayed writing this update (over 100 days since #124) because I assume that most of you would tire of hearing about the endless details of planning, building, roofing, pouring, wiring, lighting, dehumidifying, schlepping, and unpacking… at least until it was all over. I’ve been dragged deeply into things I know little about, written far too many checks for lumber, and sweated over building and electrical inspections. I can now stand around with neighboring homeowners, passin’ the time o’ day while jawin’ about soffit ventilation, pros and cons of concrete vapor barriers, and what grade of gravel is best for a driveway. It’s all been very interesting, I suppose, but finally we are turning on computers, organizing parts inventory, and thinking more about what will get the first Microship on the water than how to get a recalcitrant hank of 12-2 Romex around the overhead door.

Camano Building Construction – 2 from Steven K Roberts.

Flattening hundreds of boxes for the recycling pile while distributing their contents around the lab has a Christmas-like feel, but getting here was a dance through the minefield of costly gotchas. Humidity, for example, is not something I had to think about in California… but when BEHEMOTH’s handgrips started growing white mold and moving limp boxes revealed damp patches on the slab below, I knew we had a problem. Not only are we dealing with the mysterious concrete-curing process, but we are also perched in deep northwest woods atop a shallow island aquifer… with no gutters or French drains yet to divert rainwater from the 4″ sponge that is our floor. Those are coming, but the first Band-aid was a 50 pint/day dehumidifier that’s chugging away even as we speak, performing the ultimately hopeless task of wringing water out of the air in a forest clearing rich with mosses, ferns, nettles, and slugs.

Another grand adventure in the critical path was wiring. Like most things, this follows my adage that there is an inverse relationship between the number of words required to specify a task and the amount of time required to complete it: “Wire the building” was one unassuming item on a 5-page TO-DO list. I should have given it its own page…

We were fortunate to have consultation from a pro — Bob Hansen, an electrician on the island, was kind enough to spend some time keeping us from doing anything that diverged too far from code. We added a new breaker at the shed, splitting incoming 200A service into two 100A branches (house and lab). 750 feet of buried cable later, power pops out of a PVC pipe through the concrete slab and into the lab’s service panel. Here, ten 20A breakers feed GFI-protected chains of 4-plex outlet boxes; various 15A breakers handle some 20 fluorescent fixtures downstairs, local lighting in the offices, and a couple of 3-way circuits covering stairs and entry doors. All this is dead-simple in principle, but massive bundles of cable now adorn glue-lams, rafters, purlins, and girts… all stapled at code-specified intervals and painstakingly terminated via conduit below the 8′ level into grounded boxes.

Huge thanks go to Charlie Faddis for spending a productive weekend accelerating this process, shaking me out of my precise and aesthetically anal wiring style with the observation that our goal is to build boats, not line up all the cables perfectly. So we finished the outlets, installed IR security lights outdoors, added the ridiculously copper-inefficient 3-way circuits, passed the inspection with flying colors, and moved on.

Meanwhile, other subsystems were coming online. Fred Laun of American Action Security Systems set us up with a Napco Gemini keypad in the lab, along with motion, door, heat, and smoke sensors… linked by buried cable to the system in the house. Now we sleep better, and on my TO-DO list is tying the security system’s serial port to a server and hacking out some webbish front-end tools for graphic remote access.

In the hand-me-down karma department, we passed along our old phone system to Fred (originally donated by our friends at Asepco)… and upgraded to a very whizzy Inter-tel GLX system donated by Joe Tyner from his old business. Now we have paging, NOAA weather as music-on-hold via a dedicated Motorola marine VHF, conferencing, and the other myriad communication features that present the illusion of brisk corporate efficiency.

On the same cross-country jaunt that included the visit to Joe in St. Paul, we swung through Columbus and picked up a woodstove, courtesy of my old pal Frank Feczko. This unusually sunny summer has rendered us a bit complacent about the weather, although neighbors do shake their heads and chuckle when we casually mention that the stove is not yet installed and we haven’t quite started cutting firewood with the wicked new 20″ McCullough. I suspect there will be a mad scramble to do both, followed closely by all the auxiliary heating systems that will let epoxy set and fingers type in the extended chill of northwest winter.

We have taken one step in that direction, though — a 6×12′ woodshed grafted onto the side of the building, using leftover roofing left on the jobsite. Thanks go to Lonnie Gamble for designing this and doing most of the framing during a productive and amusing visit that also included building the second Microship workstand, tossing together a compost cage (thanks, Syndi!), and doing most of the drywall in my office (thanks, Barbara and Shariel!).

As you may recall, the building is a “monitor” style with a second, narrower floor as wide as the space between the two inner rows of poles. This gives us about 13×56′ of office space separate from the gritty realities of the lab below, with a stairway along the back wall emerging first into the “gear room,” for storage of packable goodies. A large central area comprising three bays has become known as the media lab — the place for video production with our beloved Casablanca, publication and production of monographs, sewing the boats’ bimini covers, and general office equipment. Lisa’s world is in the middle of all this, so she’s adopted the media lab as her space and taken on all the drywalling, painting, and floor sealing. Winding through this is the path to my little sanctum sanctorum, a carpeted escape when I need a quiet place to write, schmooze, or surf.

But the real thrill is the lab. I went on a bench-fabrication frenzy last week, taking advantage of the 29″ girt height to build 180 square feet of workbenches along the walls in the Zone of Hackage… a giant reverse ‘F’ shape in the southwest corner with an 8×6 projection providing a U-shaped software development lab that abuts the hub-node and console fab area (easy access to the *backs* of computers!). All this is adjacent to one of the boat bays, allowing a long in-utero packaging phase without driving everyone crazy with dangling umbilici. The other boat bay has roll-down dust-control curtains and a roll-up door, with a fiberglass shop off to the side as well as a wash-up area; remaining lab space is given over to machine shop and the huge wrap-around Hall of Inventory that segues from hundreds of small-parts drawers to a rank of shelving units and on into the tool crib and stand-up racks for sheet stock. Our latest acquisition is Big Red, a 1 HP floor-model 22-speed drill press to generate the obligatory sea of chips that quietly bespeaks “machine shop.”

All of this gave us the space to haul the goodies back from their entombment in rented storage units — four backbreaking trips to Bellingham with truck and trailer. Lisa and I are indebted to Jerry Moa, Mike Nestor, Doug Scoggins, Dewayne Hendricks, Mike Setzer, and Mary Davis for their invaluable physical help during various phases of this seemingly endless process.

And so, it’s over. Other than occasional minor tweaks and additions, you’ve just read my final commentary about the epic lab quest and building adventure… we’re now back into the Microship project full-time!

NRL EXPANDING OPERATIONS 😉

CAMANO ISLAND, WA (August 24, 1998) PR HOTLINE. Nomadic Research Labs announced today that it has acquired first-round funding from an unnamed offshore venture consortium to develop large-scale manufacturing capability for the company’s line of Internet-connected recumbent bicycles, kayaks, and backpacks. Spurred by rising demand from the growing population of RACONTEURS (Restless Affluent Corporate Oldtimers Now Taking Extended Unpaid Recovery Sabbaticals), the market for technomadic systems and accessories has more than tripled in the past year.

Steve Roberts, director of NRL’s west coast facility on Camano Island, is characteristically effusive about this new development in his company’s operations. “We’ve set our sights on corporate America,” he said. “After observing obvious wistful longing in the audience during hundreds of speaking engagements around the US, it dawned on me that we’re sitting on a gold mine. Cubicle Denizens everywhere are crying out for release, and we have exactly what they need — a way to reach escape velocity.”

Reflected in the company’s slogan, “Don’t get mad, get nomadic!” the Nomadic Research Labs solution to the stresses of the torporate lifestyle is deceptively simple: hit the road, but keep consulting. Few can afford to take early retirement for a life of full-time vagabonding, but if integrated computers and net connections are added to the hobo’s toolkit, then any information worker can become productively homeless. Until now, NRL offered only “do it yourself” how-to guides for building BEHEMOTH and Microship clones. As these manuals run into the thousands of pages and require many years of well-funded dedicated effort, however, the number of successfully completed projects has been understandably low.

The new manufacturing facility located in the sprawling woods near the company’s research facility on Camano Island is expected to employ upwards of 150 technology workers, with product rollout commencing in second quarter, 1999. First off the line is a mass-market version of the CyberFanny, a small wearable system integrating basic technomadic tools in a handsome mauve cordura shell with fold-out solar panel and “rib tickler” antennas. By early 2000, NRL is predicting beta testing of a sealed modular console system suited for integration into recumbent bicycles, kayaks, snowmobiles, hang-gliders, and ultralight aircraft (the Supreme Court decision on the landmark “Chord Keyboard Killings” case prohibits attention-diverting technomadic systems in licensed on-road vehicles or General Aviation aircraft).

Projections by the Gartner Group extrapolate current Corporate Refugee trends into a $100 million industry by the turn of the century, and Nomadic Research Labs is positioning itself to capture an estimated 85% market share. As noted yuppie hobo spokesman “Veep” Hawkins observed last year during a boxcar press conference in the Kansas City yards, “pretty soon everybody’s going to be out here, and if I had a dime for every burned out engineer sticking out his thumb I’d turn in my stock options.”

Nomadic Research Labs (Nasdaq NRL) was founded in 1983, and is dedicated to providing technomadic solutions and support systems.

CROSS-COUNTRY TOUR REPORT

Ahem.

We’ve done another Mothership jaunt since the last update — a 7,500-mile cross-country drive to Virginia and back. The key event was a speaking gig for the Cabletron Government Users Conference in Williamsburg, with mostly-social stops enroute and lots of camping and hiking in the company of the latest addition to our family — the Maine Coonish kitten known as Dr. Java C. Furberger.

The diesel truck threw me an interesting curve… after a full week of hard driving including a night of careening through Appalachian Mountain back roads, we were on the home stretch… four hours until showtime, watching the street numbers counting down to the conference hotel. Suddenly the truck started pulling to the left, and when a quick peek at a stop light showed no impending flat tire I pressed on with the intent of dealing with it later.

A block later we reached our objective and turned into the parking lot… whereupon the brake pedal, in a masterstroke of good timing, went smoothly to the floor and smoke poured out of the left front wheel. Ehhh? Turned out that the caliper pistons, made of PLASTIC, of all things, had overheated and initiated a catastrophic positive-feedback event in which the brakes dragged, heating even more, at last seizing up, boiling the brake fluid and destroying the whole assembly. The heroic mobile repair service guy handled it the next morning for a most reasonable cost, but I remain shocked that Ford would use plastic pistons in this critical area (but hey, what do I know about automotive engineering?).

Actually, Biggus Truckus has been a wonderfully reliable workhorse, handling dozens of cross-country towing jobs with nary a belch. We had some apparent altitude problems in Colorado, belching and guttering, smoking and wheezing… but it turned out to be only the demise of my well-amortized fuel filter. Monarch Pass passed without incident.

One of the highlights of this whirlwind tour (a bit rushed because what we REALLY wanted was to get back and finish the building) was a quick stop at the headwaters of the Missouri River near Three Forks, Montana — a recon mission to the projected launch point for the Microships’ Coastal/Inland Tour. Remote and wild, it seems a fitting site for a sendoff party… and all along, every time we crossed or paralleled the Missouri, Mississippi, or Ohio, we would crane our necks like gawking tourons, visualizing solar-encrusted microtrimarans, bristling with antennae, scudding briskly downriver. One o’ these days…

Like all road trips, it was rife with surprise moments and oddities: camping across from the Museum of Flywheels in Kansas, exposing the kitten to the huge world of other critters and Big Places, watching divers work a car wreck in a small pond beside an arrow-straight North Dakota freeway, camping at Hot Lake in Oregon, doing the campground laptop email dance at KOA’s various, clambering in the Rockies and Arches National Park, and visiting lots of friends as well as some of our interesting present and future sponsors (Solarex, Qualcomm, Xybernaut). As always by motorcar, it was way too fast… missing more than we saw, regretting the visits not made, vowing to return by human-scale Microship as I did, long ago, on a machine so ponderously slow that every tactile and olfactory detail of the land could be observed, pondered, recorded, and later recounted.

JAMMIN’ ON THE DELTA

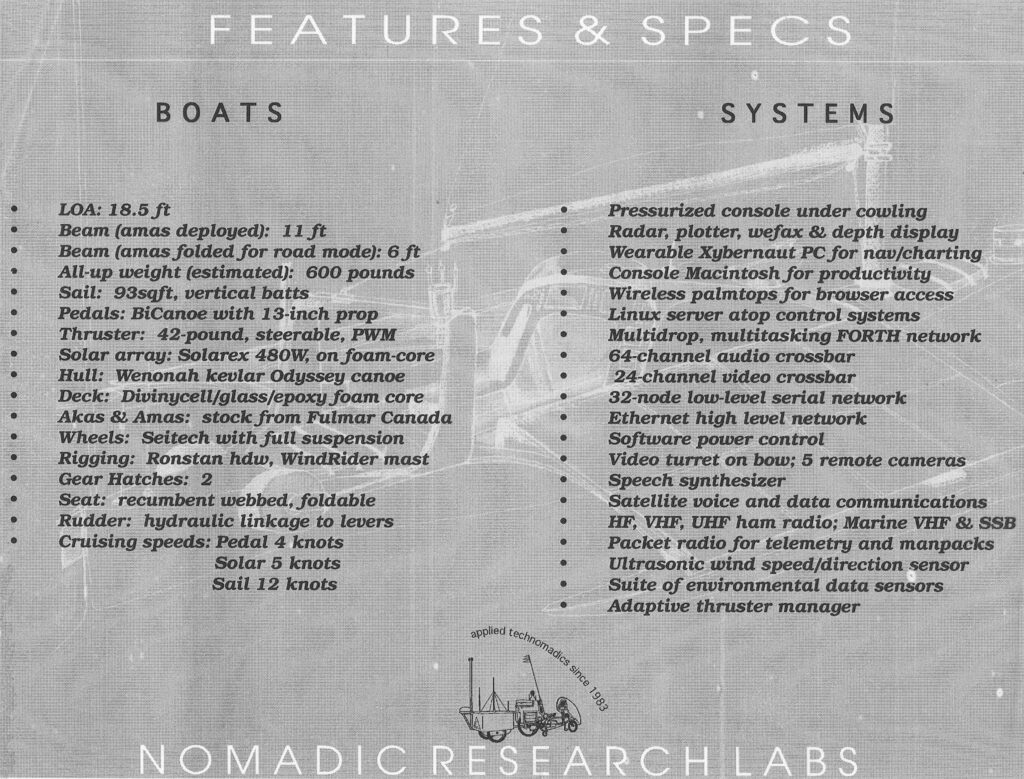

With that in mind, and with the building fading into the background, we’re hard at it again. Bob Stuart has returned to weave his fiberglass magic and help with key fabrication projects, and we’re on a mission: to sail around south Whidbey to Port Townsend, arriving in time for me to speak at the Sea Kayak Symposium on Sept 18-19. This is, of course, insane, given the number of basic components yet to be built and tested, but what the hell — nothing like a deadline to kick things into high gear. The general plan is to take two boats, the second being a Fulmar-19 on loan from Cy Hernandez (the same tri that Faun used on our gonzo symposium mission exactly four years earlier… see link below).

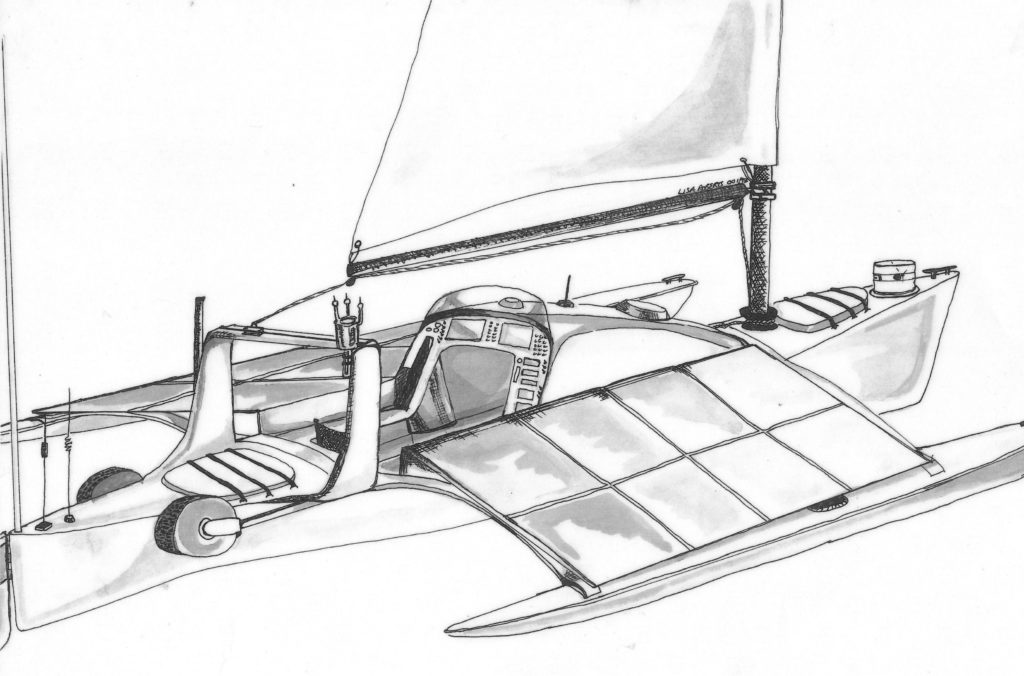

Getting from here to there involves a huge number of projects, large and small. We have to bolt on the akas, mount the recumbent seat in a way that allows adjustability and retraction for sleeping, temporarily hang the rudder to allow on-water fine-tuning of helm balance before attaching it permanently, fabricate rev-1 pedals and mount the deployable drive unit, acquire and install the full suite of mainsheet rigging components, paint or gelcoat the deck to protect the epoxy from UV, add basic deck fixtures, hack a temporary power system for VHF and lighting, install steering controls with hydraulic linkage or something temporary, finish the basics like hatch tie-downs and daggerboard handling, and so on. It would also be nice to get the landing gear working, so Bob has been doing suspension analysis and specifying parts for that as well. Madness, delicious madness.

Meanwhile, I’m reassembling the control system (hub, crossbars, nodes, turret, and such) with the intent of starting the new on-board server project — an embedded linux box that supports connections from various browsers for boat control and monitoring. This will allow a consistent front end from Delta and Wye local consoles, wireless backpack palmtops, and remote secure net connection. All this, of course, involves YALC (Yet Another Learning Curve), so we took an old AT 386 box donated by Joe Tyner, parked at Bdale Garbee’s house in Colorado Springs for an evening, and installed the latest release of Debian linux. When the time comes to choose a tiny server for the boat, we’ll drop in a teensy board with loads of flash memory… but for now, we have a desktop development system with connectors chunky enough to solder.

This is probably a good time to mention that we could use help with this… there are a number of projects that would benefit from a distributed team of linux, Mac, and Pilot programmers (as well as web designers and database gurus). Also, don’t forget our ongoing “Geek’s Vacation” program… now that we have a place, we’re welcoming folks who want to immerse themselves in some part of the project. Tim Nolan is arriving next week from Wisconsin to work on power management and thruster control… if you’re interested, speak up!

NEWS UPDATES

We have, as usual, a number of random news bits…

First, mea culpa on leaving out “http://” in the links in issue #124… and thanks to messrs. Feldman, Vodall, and Purcell for pointing out that web-savvy mail readers need that to display them as clickable links.

We had a few media appearances since the last update — one page articles in Outside and Outpost, a piece in the Italian Forbes-like magazine Capital, and an interview with the wonderful Recumbent UK magazine (yes, recumbents are coming of age!). We also did an interview with the wandering Quest-4 guys, who are exploring the various meanings of success while making a grand loop around the US — a sort of self-referential odyssey of exploration.

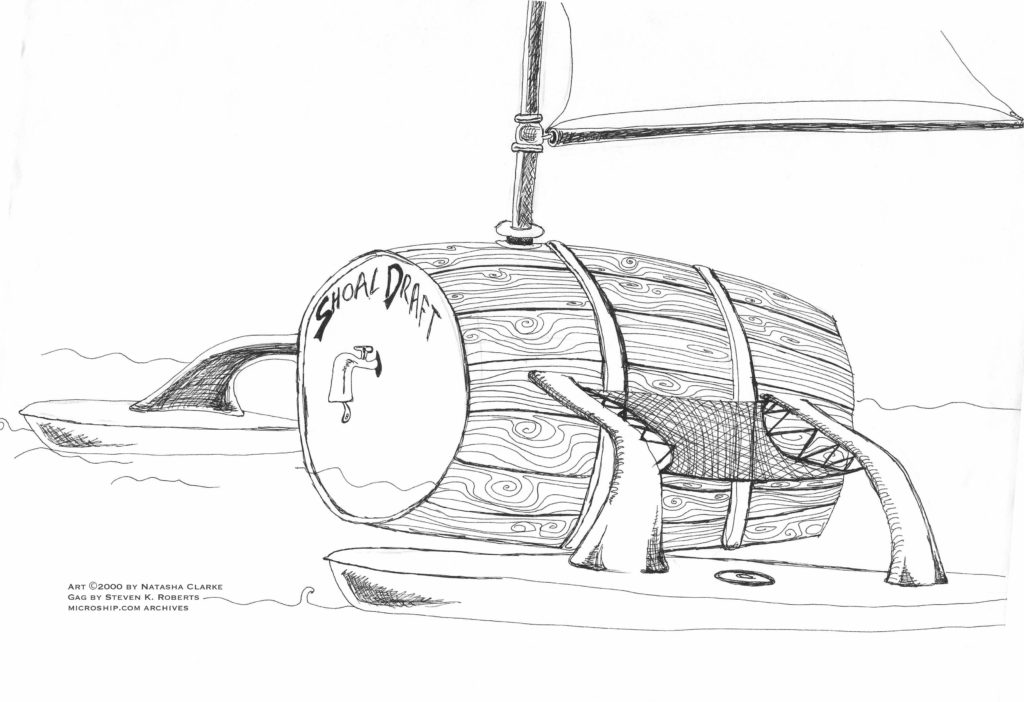

Lisa and I are working on a few publishing projects, and just for kicks have started a cartoon series. Since I tend to spew unforgivable puns and she’s an artist (see her Microship drawing referenced below), it’s a natural alliance. We just made our first sale, to Multihulls Magazine: a picture of a trimaran whose center hull is a giant beer barrel with a tap… labeled “Shoal Draft.”

I’m also writing the LONG overdue Microship technical overview to replace the ancient version that we recently deleted from the website… it should be up Real Soon Now. And we have about 75 planned monograph titles that should keep me busy during those spare moments that pop up once every few weeks.

Upcoming events include a keynote at the TAPR Digital Communications Conference in Chicago (9/25) and, presumably, delivery of BEHEMOTH to the Tech Museum of Innovation in San Jose sometime in October IF we can put together a Silicon Valley speaking tour in the short time remaining. I’d like to drive down in early October, make the rounds of high-tech companies to do on-site BEHEMOTH presentations, then leave it with the museum. If you work for a company in the Bay Area and want to make this happen, or want to put it all together for a piece of the action, please let me know ASAP…

Finally, now that we’re actually getting back to work, the obtainium quest is again in full swing… time to start assembling comm/nav systems and other key tools! Thanks go to our first new technology sponsor in quite a while: KR7KZ has donated a couple of beautifully crafted dual-band J-pole antennas that can handle the marine environment… all stainless, anodized aluminum, and Delrin.

Damn, it feels good to be back at something that doesn’t involve the Skilsaw…

Back to it!

You must be logged in to post a comment.