Harbor Digitizing in Microsiervos

This site in Spain posted a story about my digitizing activities, and quite surprised me with a flurry of web traffic and a few inquiries about home movie archives. According to Google Translate, the title reads, “The veteran technomad who could digitize any audio, video, film or photo format.” Since this is such a good…

Read MoreWizard with a Time Machine

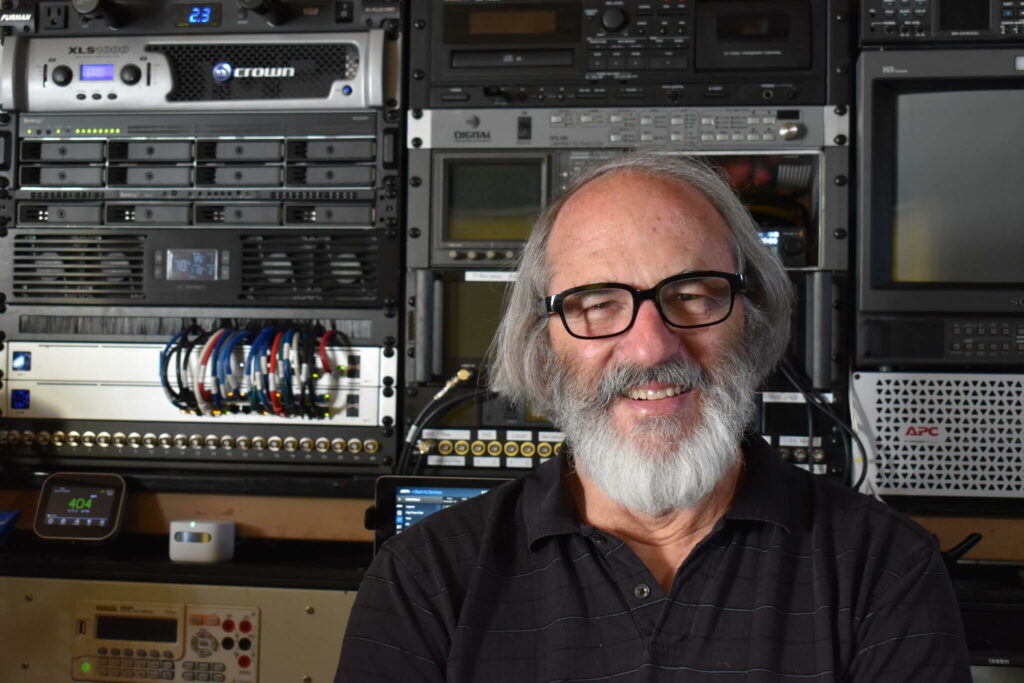

By Kelley Balcomb-Bartok Journal of the San Juan Islands July 19, 2022 Located in an unassuming building in Friday Harbor is a magical place inhabited by a wizard of technology bringing history back to life for clients and friends. Steven K. Roberts is his name, digitizing old films, videos and slides is his game. Harbor…

Read MoreReality 2.0 Interview with Doc Searls

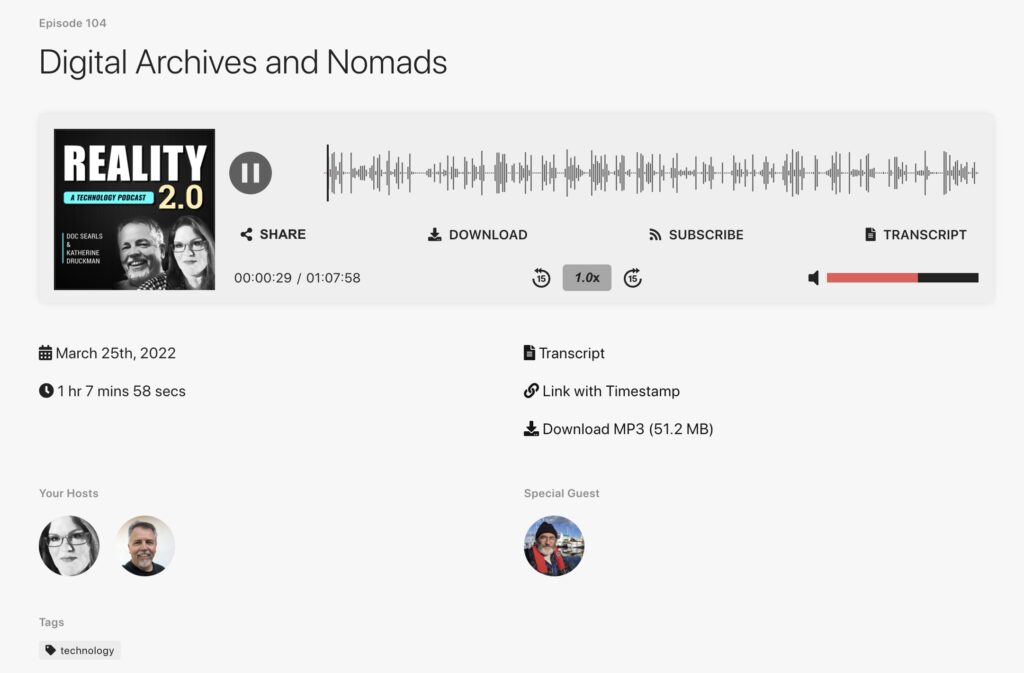

“Digital Archives and Nomads” Ages ago, on the Perl Whirl and Linux Lunacy geek cruises, I had the pleasure of hanging out with the legendary Doc Searls, editor of Linux Journal and co-author of Cluetrain Manifesto along with lots of other things. He also created the FLOSS Weekly podcast, has been a vocal proponent of…

Read MoreThe first digital nomad – Fast Company article

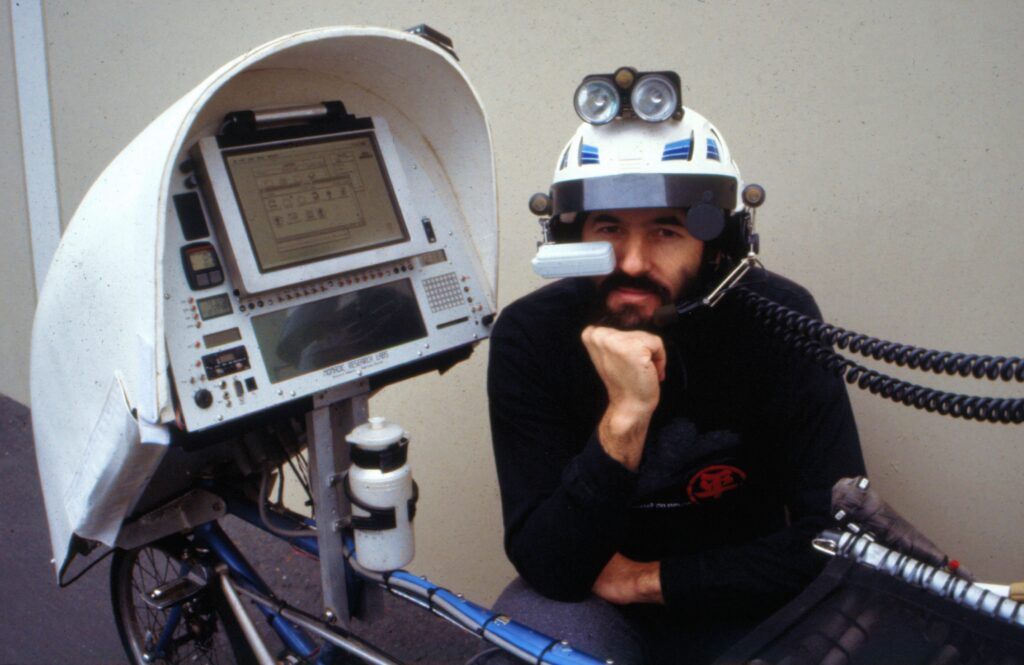

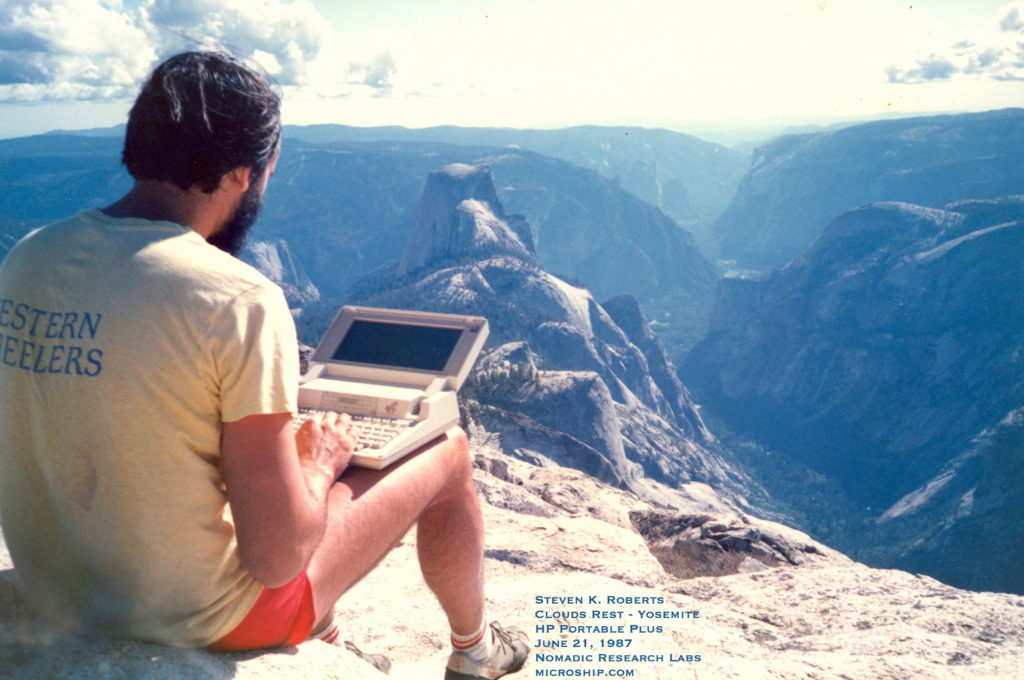

It is a treat, here in late 2021, to see this article make a splash on that newfangled “social media.” How far we’ve come in a third of a century… with the essential tools to enable a truly mobile lifestyle now in every pocket and backpack. When I took off on a “computerized recumbent bicycle”…

Read MoreA Cruiser for Mobility

by Steven K. Roberts Friday Harbor, Washington As this paleo-technomad pushes seventy (!) there have been a few reminders of mortality… not to mention a noticeable reluctance to go gallivanting up hills every time I need something. This has become more of an issue lately with a little medical distraction, so my first solution, given…

Read MoreIn Death: Unchained – Literature Archive

by Steven K. Roberts updated: April 28, 2024 Latest updates: Two tracks from the Songs of Cupid album by Ichor are now available! Also, Gabriel does an IDU run with a smuggled VR headset and we chat with Salvo the Unmerciful (the author of Brutal Arrows, modeling his formal robes in the photo above). The…

Read MoreThe Consoles of my Life

Over the years, there has been one stylistic constant in my pursuit of übergeekery: equipment consoles. It started one 1964 afternoon in Louisville, when this skinny 12-year-old electronics-obsessed geeklet got a peek at how the big boys do it. Via a ham radio friend, I had wangled an invitation to visit the avionics maintenance shop…

Read MoreDigitizing in a Pandemic

Coronavirus will echo for decades. Everything was normal… then suddenly we were on sabbatical from our own timelines, routines disrupted by intimations of mortality… priorities shifted, values inverted, unspeakable things whispered, stats obsessively reloaded. We watch the news in horror, contemplate de-facto partnerships, ache at disconnections, and muse about the messes we will leave behind…

Read MoreAn Underwater Exploration Toolkit for Boats

Tools for exploring the aquatic environment by Steven K. RobertsNomadic Research Labs — May 4, 2018 One of the strongest motivations behind the Datawake project is to extend my human sensorium, letting me see into otherwise invisible realms. This takes many forms: data collection systems fed by environmental sensors, embedded probes that report conditions I would never otherwise…

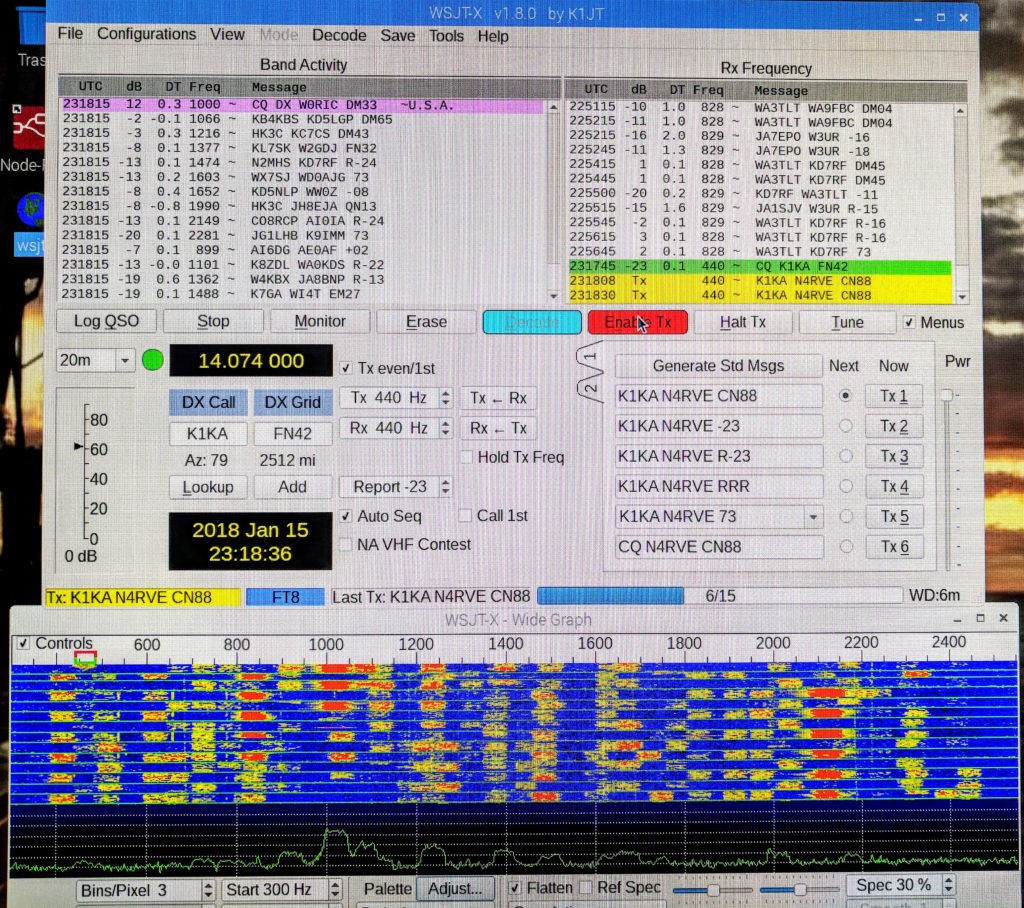

Read MoreMaritime Mobile FT8 Amateur Radio

I’ve recently been enjoying immersion in a sort of ham radio for introverts… a new digital mode called FT8 that allows weak-signal communication on all the HF bands from 160 to 6 meters via tiny 50Hz-wide signals exchanged by time-synchronized computers running WSJT-X. A complete exchange takes a minute and a half, with the connected machines…

Read More

You must be logged in to post a comment.